OPERATION | ||

|

|

|

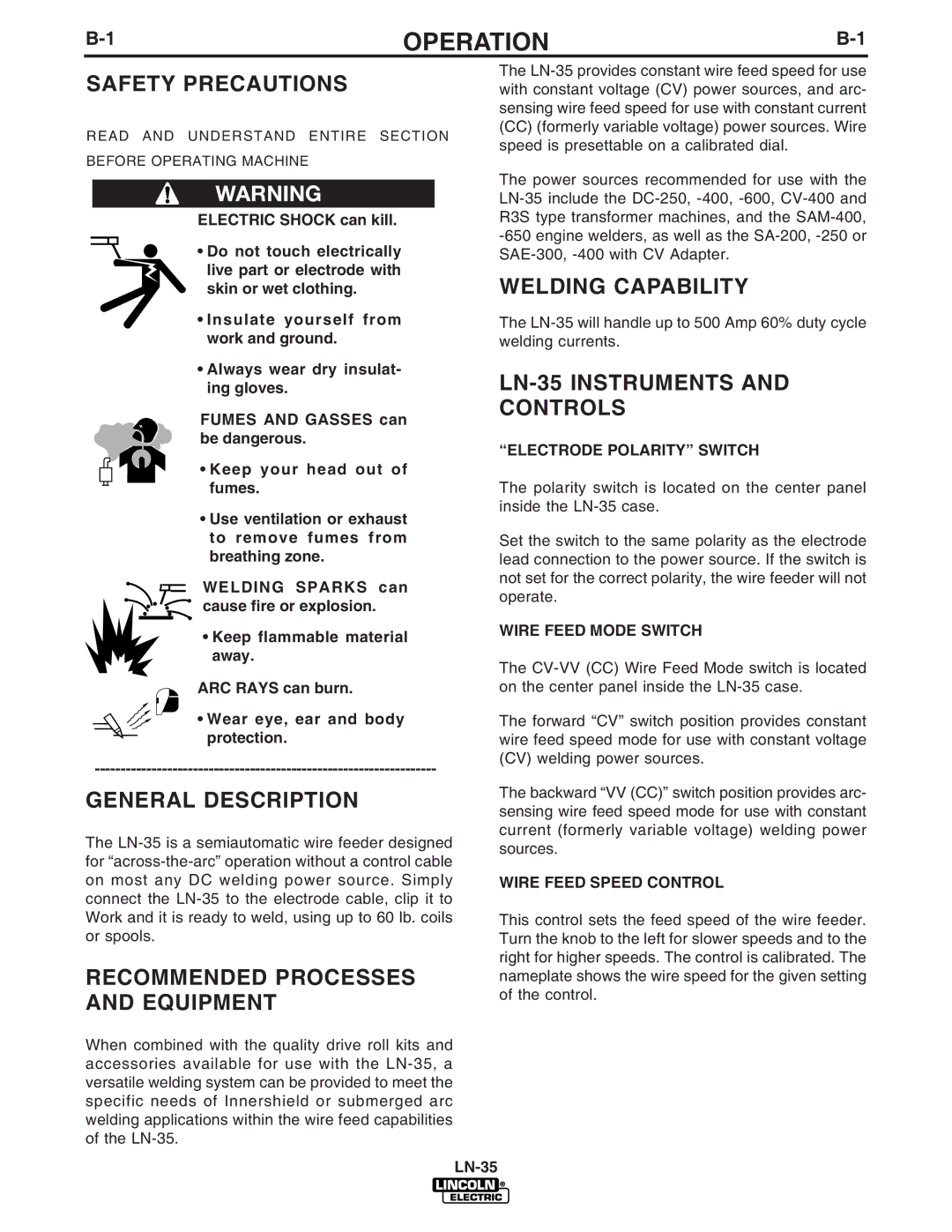

SAFETY PRECAUTIONS

READ AND UNDERSTAND ENTIRE SECTION

BEFORE OPERATING MACHINE

The

(CC)(formerly variable voltage) power sources. Wire speed is presettable on a calibrated dial.

WARNING

ELECTRIC SHOCK can kill.

• Do not touch electrically live part or electrode with skin or wet clothing.

•Insulate yourself from work and ground.

•Always wear dry insulat- ing gloves.

FUMES AND GASSES can be dangerous.

• Keep your head out of fumes.

•Use ventilation or exhaust to remove fumes from breathing zone.

WELDING SPARKS can cause fire or explosion.

•Keep flammable material away.

ARC RAYS can burn.

• Wear eye, ear and body protection.

GENERAL DESCRIPTION

The

RECOMMENDED PROCESSES AND EQUIPMENT

When combined with the quality drive roll kits and accessories available for use with the

The power sources recommended for use with the

WELDING CAPABILITY

The

LN-35 INSTRUMENTS AND CONTROLS

“ELECTRODE POLARITY” SWITCH

The polarity switch is located on the center panel inside the

Set the switch to the same polarity as the electrode lead connection to the power source. If the switch is not set for the correct polarity, the wire feeder will not operate.

WIRE FEED MODE SWITCH

The

The forward “CV” switch position provides constant wire feed speed mode for use with constant voltage (CV) welding power sources.

The backward “VV (CC)” switch position provides arc- sensing wire feed speed mode for use with constant current (formerly variable voltage) welding power sources.

WIRE FEED SPEED CONTROL

This control sets the feed speed of the wire feeder. Turn the knob to the left for slower speeds and to the right for higher speeds. The control is calibrated. The nameplate shows the wire speed for the given setting of the control.