INSTALLATION | ||

|

|

|

10.Install with arm section with the six 1/2" x

11.Raise the front of the arm with a forklift or hoist and attach to the appropriate hole in the clevis and arm triangle.

12.Install the cover plate at the top of the stanchion.

13.Install the optional

14.Route the control cable, gas hose and electrode cable through the center tube.

15.Slip the 3' (0.9m) long, 2" (51 mm) diameter black hose over the assembled cables and hose at the rear of the arm.

16.Slip the 1' (0.3m) long, 2" (51 mm) diameter black hose over the assembled cables at the front of the arm.

17.Slip the 4" (102 mm) of PVC tube over the gas hose(s).

18.Secure the welding arm to prevent movement.

![]() WARNING

WARNING

Secure the welding arm to prevent movement before mounting wire feeder, cables, or any other accessory.

The Universal Wire Feeder Mounting Bracket has holes for mounting:

•

•

•

•Power Feed 10 and Power Feed 10M

•Power Feed 10 Dual and Power Feed 10M Dual

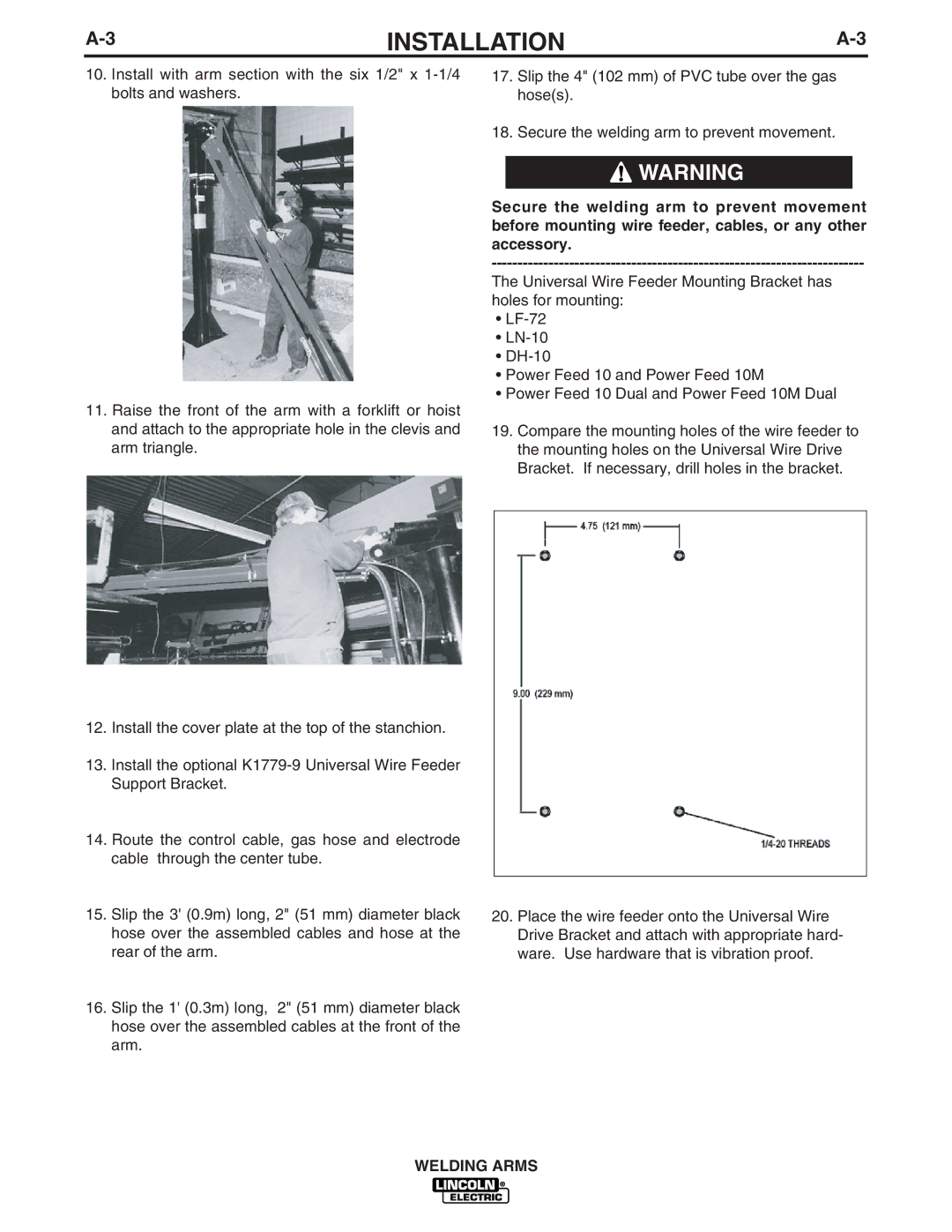

19.Compare the mounting holes of the wire feeder to the mounting holes on the Universal Wire Drive Bracket. If necessary, drill holes in the bracket.

20.Place the wire feeder onto the Universal Wire Drive Bracket and attach with appropriate hard- ware. Use hardware that is vibration proof.

WELDING ARMS