INSTALLATION | ||

|

|

|

21.Adjust the length of the cables and hoses coming out of the front of the arm to permit connections to the feeder.

22.Secure the cables and hoses to the

![]() CAUTION

CAUTION

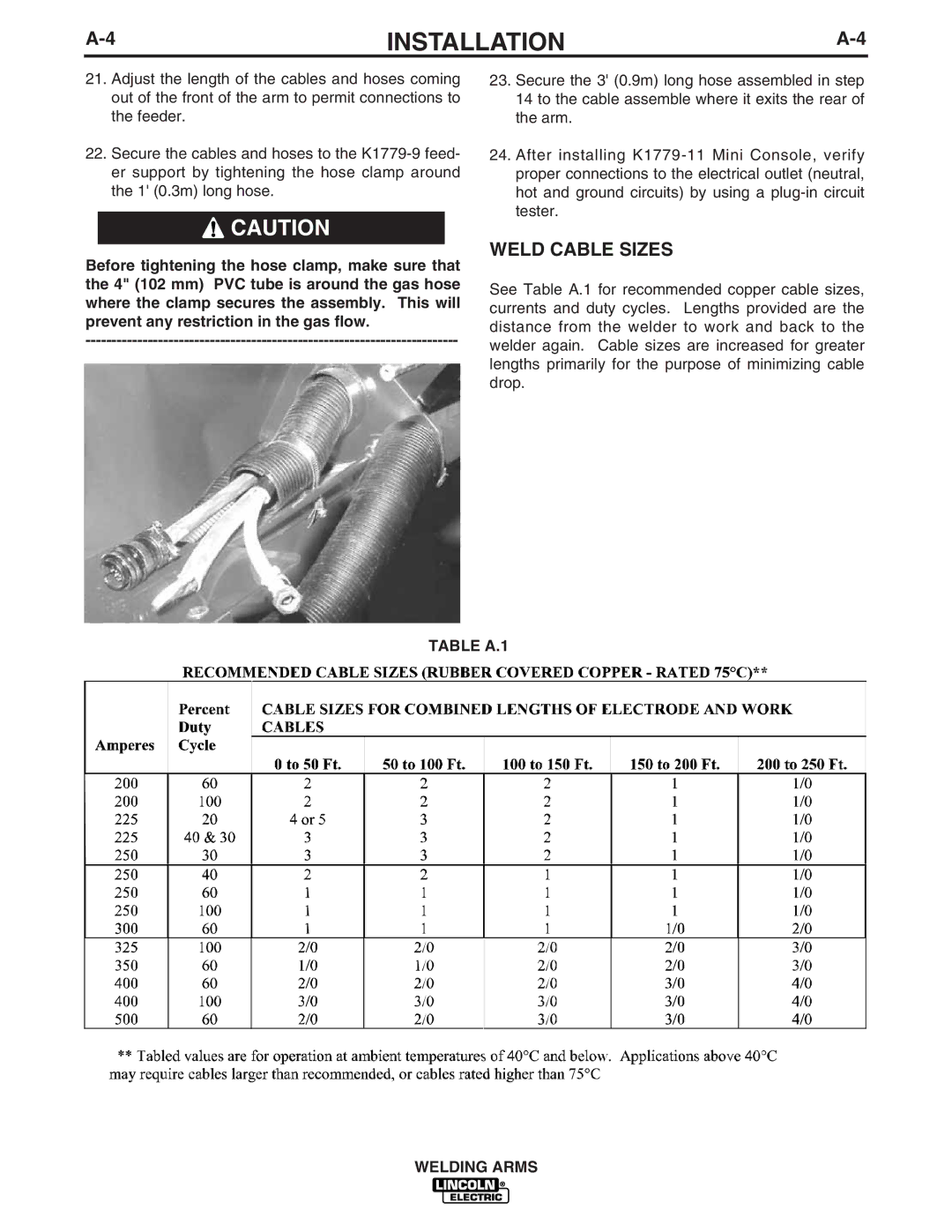

Before tightening the hose clamp, make sure that the 4" (102 mm) PVC tube is around the gas hose where the clamp secures the assembly. This will prevent any restriction in the gas flow.

23.Secure the 3' (0.9m) long hose assembled in step 14 to the cable assemble where it exits the rear of the arm.

24.After installing

WELD CABLE SIZES

See Table A.1 for recommended copper cable sizes, currents and duty cycles. Lengths provided are the distance from the welder to work and back to the welder again. Cable sizes are increased for greater lengths primarily for the purpose of minimizing cable drop.

TABLE A.1

WELDING ARMS