HEATING SEQUENCE OF OPERATION Ð See Fig. 26-33 and unit wiring label.

On a call for heating, terminal ``W'' of the thermostat is energized, starting the induced-draft motor. When the hall- effect sensor on the induced-draft motor senses that it has reached the required speed, the burner sequence begins. This function is performed by the integrated gas control (IGC). The evaporator-fan motor is energized 45 seconds after flame is established. When the thermostat is satis®ed and ``W'' is deenergized, the burners stop ®ring and the evaporator-fan motor shuts off after a 45-second time-off delay.

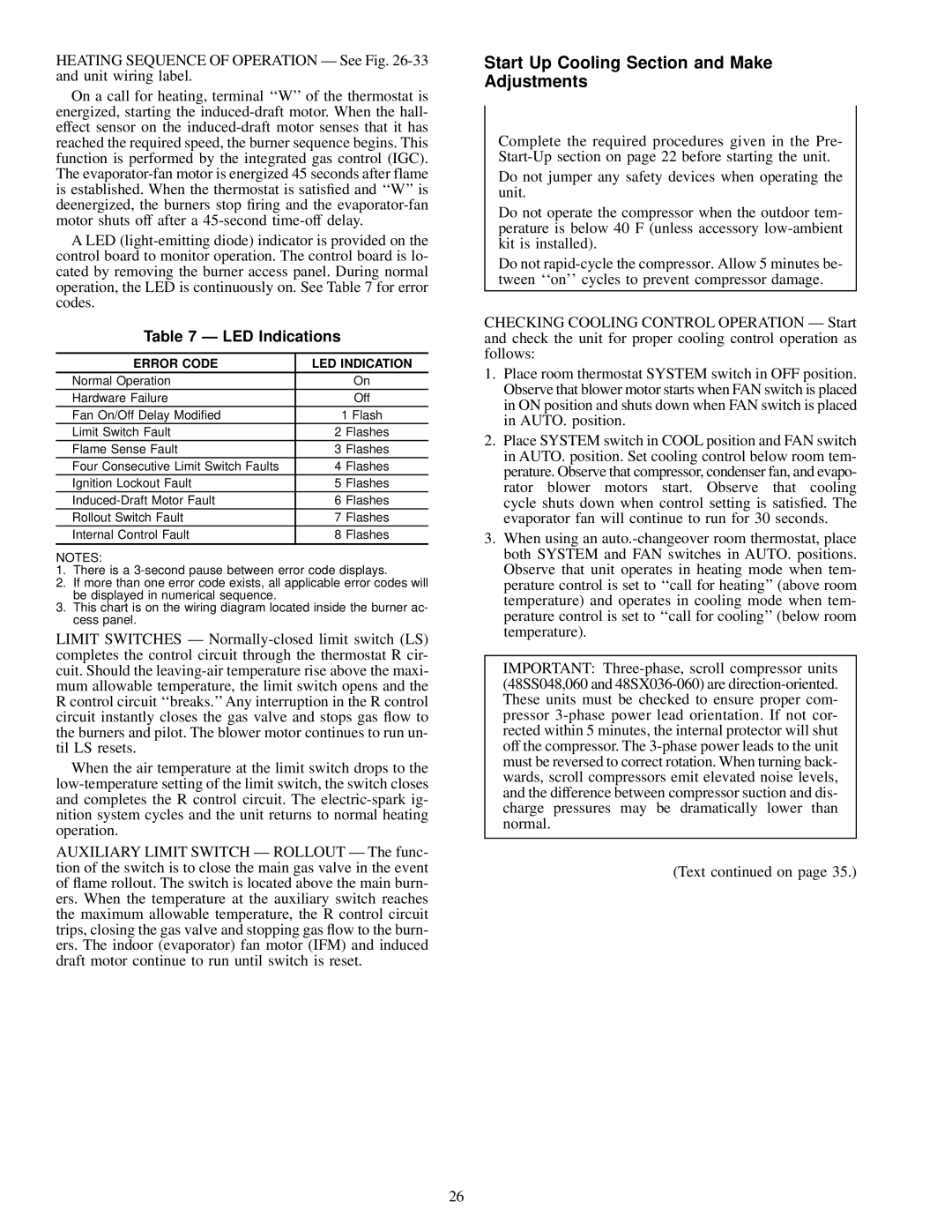

A LED (light-emitting diode) indicator is provided on the control board to monitor operation. The control board is lo- cated by removing the burner access panel. During normal operation, the LED is continuously on. See Table 7 for error codes.

Table 7 Ð LED Indications

ERROR CODE | LED INDICATION |

Normal Operation | On |

Hardware Failure | Off |

Fan On/Off Delay Modi®ed | 1 Flash |

Limit Switch Fault | 2 Flashes |

Flame Sense Fault | 3 Flashes |

Four Consecutive Limit Switch Faults | 4 Flashes |

Ignition Lockout Fault | 5 Flashes |

Induced-Draft Motor Fault | 6 Flashes |

Rollout Switch Fault | 7 Flashes |

Internal Control Fault | 8 Flashes |

| |

NOTES:

1.There is a 3-second pause between error code displays.

2.If more than one error code exists, all applicable error codes will be displayed in numerical sequence.

3.This chart is on the wiring diagram located inside the burner ac- cess panel.

LIMIT SWITCHES Ð Normally-closed limit switch (LS) completes the control circuit through the thermostat R cir- cuit. Should the leaving-air temperature rise above the maxi- mum allowable temperature, the limit switch opens and the R control circuit ``breaks.'' Any interruption in the R control circuit instantly closes the gas valve and stops gas ¯ow to the burners and pilot. The blower motor continues to run un- til LS resets.

When the air temperature at the limit switch drops to the low-temperature setting of the limit switch, the switch closes and completes the R control circuit. The electric-spark ig- nition system cycles and the unit returns to normal heating operation.

AUXILIARY LIMIT SWITCH Ð ROLLOUT Ð The func- tion of the switch is to close the main gas valve in the event of ¯ame rollout. The switch is located above the main burn- ers. When the temperature at the auxiliary switch reaches the maximum allowable temperature, the R control circuit trips, closing the gas valve and stopping gas ¯ow to the burn- ers. The indoor (evaporator) fan motor (IFM) and induced draft motor continue to run until switch is reset.

Start Up Cooling Section and Make Adjustments

Complete the required procedures given in the Pre- Start-Up section on page 22 before starting the unit.

Do not jumper any safety devices when operating the unit.

Do not operate the compressor when the outdoor tem- perature is below 40 F (unless accessory low-ambient kit is installed).

Do not rapid-cycle the compressor. Allow 5 minutes be- tween ``on'' cycles to prevent compressor damage.

CHECKING COOLING CONTROL OPERATION Ð Start and check the unit for proper cooling control operation as follows:

1.Place room thermostat SYSTEM switch in OFF position. Observe that blower motor starts when FAN switch is placed in ON position and shuts down when FAN switch is placed in AUTO. position.

2.Place SYSTEM switch in COOL position and FAN switch in AUTO. position. Set cooling control below room tem- perature. Observe that compressor, condenser fan, and evapo- rator blower motors start. Observe that cooling cycle shuts down when control setting is satis®ed. The evaporator fan will continue to run for 30 seconds.

3.When using an auto.-changeover room thermostat, place both SYSTEM and FAN switches in AUTO. positions. Observe that unit operates in heating mode when tem- perature control is set to ``call for heating'' (above room temperature) and operates in cooling mode when tem- perature control is set to ``call for cooling'' (below room temperature).

IMPORTANT: Three-phase, scroll compressor units (48SS048,060 and 48SX036-060) are direction-oriented. These units must be checked to ensure proper com- pressor 3-phase power lead orientation. If not cor- rected within 5 minutes, the internal protector will shut off the compressor. The 3-phase power leads to the unit must be reversed to correct rotation. When turning back- wards, scroll compressors emit elevated noise levels, and the difference between compressor suction and dis- charge pressures may be dramatically lower than normal.

(Text continued on page 35.)