UNITS WITH OPTIONAL BASE RAIL Ð Lifting holes are provided in optional base rail as shown in Fig. 13. Op- erating weights are shown in Tables 1 and 2. Refer to rig- ging instructions on unit.

Protective wood support must be removed from unit be- fore unit is mounted to curb. Remove 4 screws that secure support above rigging holes in rails. Slide support out through rectangular hole in rail. See Fig. 13.

Step 6 Ð Connect Condensate Drain

NOTE: When installing condensate drain connection be sure to comply with local codes and restrictions.

Model 48SS,SX disposes of condensate water through a 3¤4 in. NPT ®tting which exits through the compressor access panel. See Fig.

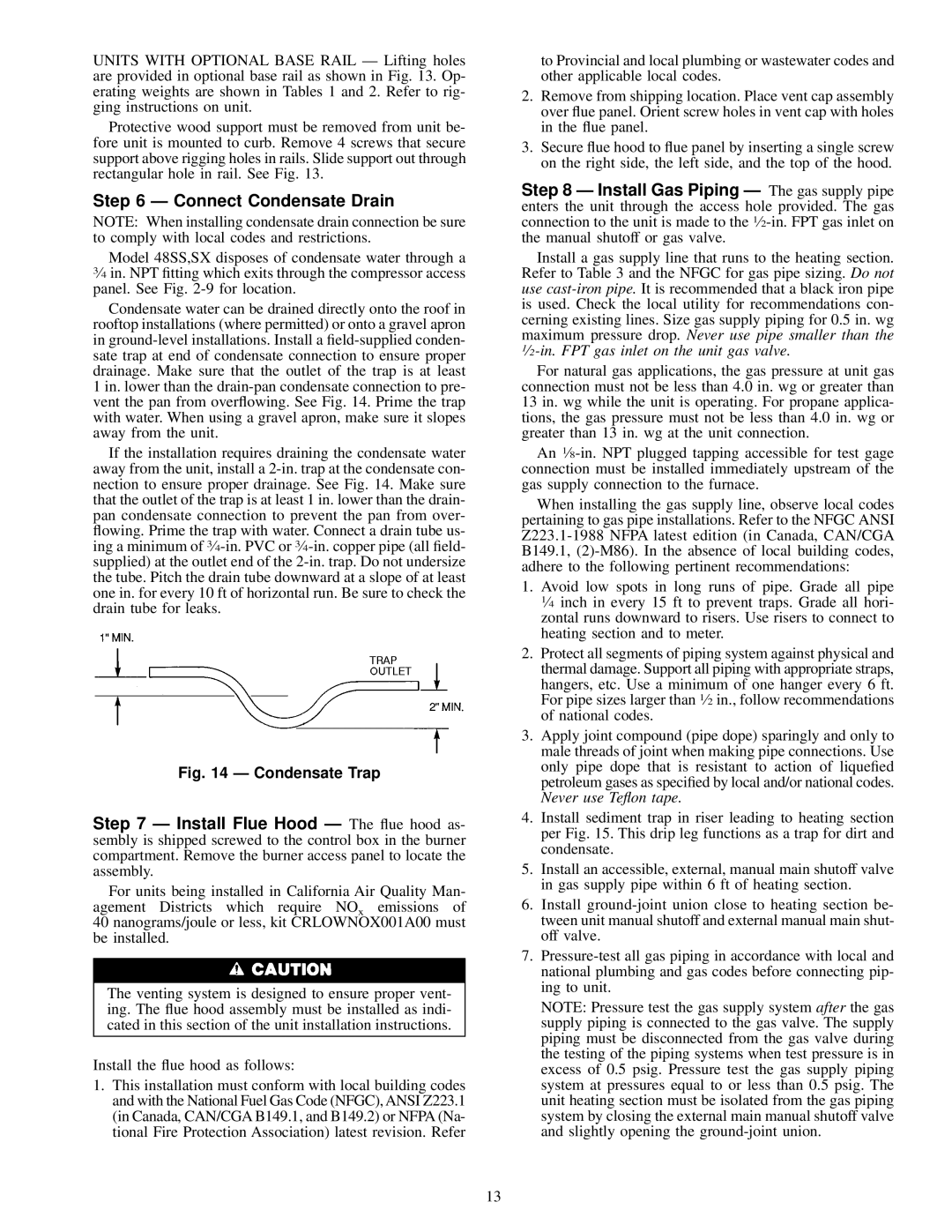

Condensate water can be drained directly onto the roof in rooftop installations (where permitted) or onto a gravel apron in

If the installation requires draining the condensate water away from the unit, install a

Fig. 14 Ð Condensate Trap

Step 7 Ð Install Flue Hood Ð The ¯ue hood as- sembly is shipped screwed to the control box in the burner compartment. Remove the burner access panel to locate the assembly.

For units being installed in California Air Quality Man- agement Districts which require NOx emissions of 40 nanograms/joule or less, kit CRLOWNOX001A00 must be installed.

The venting system is designed to ensure proper vent- ing. The ¯ue hood assembly must be installed as indi- cated in this section of the unit installation instructions.

Install the ¯ue hood as follows:

1.This installation must conform with local building codes and with the National Fuel Gas Code (NFGC), ANSI Z223.1 (in Canada, CAN/CGA B149.1, and B149.2) or NFPA (Na- tional Fire Protection Association) latest revision. Refer

to Provincial and local plumbing or wastewater codes and other applicable local codes.

2.Remove from shipping location. Place vent cap assembly over ¯ue panel. Orient screw holes in vent cap with holes in the ¯ue panel.

3.Secure ¯ue hood to ¯ue panel by inserting a single screw on the right side, the left side, and the top of the hood.

Step 8 Ð Install Gas Piping Ð The gas supply pipe enters the unit through the access hole provided. The gas connection to the unit is made to the

Install a gas supply line that runs to the heating section. Refer to Table 3 and the NFGC for gas pipe sizing. Do not use

For natural gas applications, the gas pressure at unit gas connection must not be less than 4.0 in. wg or greater than 13 in. wg while the unit is operating. For propane applica- tions, the gas pressure must not be less than 4.0 in. wg or greater than 13 in. wg at the unit connection.

An

When installing the gas supply line, observe local codes pertaining to gas pipe installations. Refer to the NFGC ANSI

1.Avoid low spots in long runs of pipe. Grade all pipe 1¤4 inch in every 15 ft to prevent traps. Grade all hori- zontal runs downward to risers. Use risers to connect to heating section and to meter.

2.Protect all segments of piping system against physical and thermal damage. Support all piping with appropriate straps, hangers, etc. Use a minimum of one hanger every 6 ft. For pipe sizes larger than 1¤2 in., follow recommendations of national codes.

3.Apply joint compound (pipe dope) sparingly and only to male threads of joint when making pipe connections. Use only pipe dope that is resistant to action of lique®ed petroleum gases as speci®ed by local and/or national codes. Never use Te¯on tape.

4.Install sediment trap in riser leading to heating section per Fig. 15. This drip leg functions as a trap for dirt and condensate.

5.Install an accessible, external, manual main shutoff valve in gas supply pipe within 6 ft of heating section.

6.Install

7.

NOTE: Pressure test the gas supply system after the gas supply piping is connected to the gas valve. The supply piping must be disconnected from the gas valve during the testing of the piping systems when test pressure is in excess of 0.5 psig. Pressure test the gas supply piping system at pressures equal to or less than 0.5 psig. The unit heating section must be isolated from the gas piping system by closing the external main manual shutoff valve and slightly opening the

13