30%W E L D I N G IncreaseC O N S U M A B L E S in Productivity

UltraCore | ® | Owen Steel Company, Columbia, SC |

|

| |

|

|

|

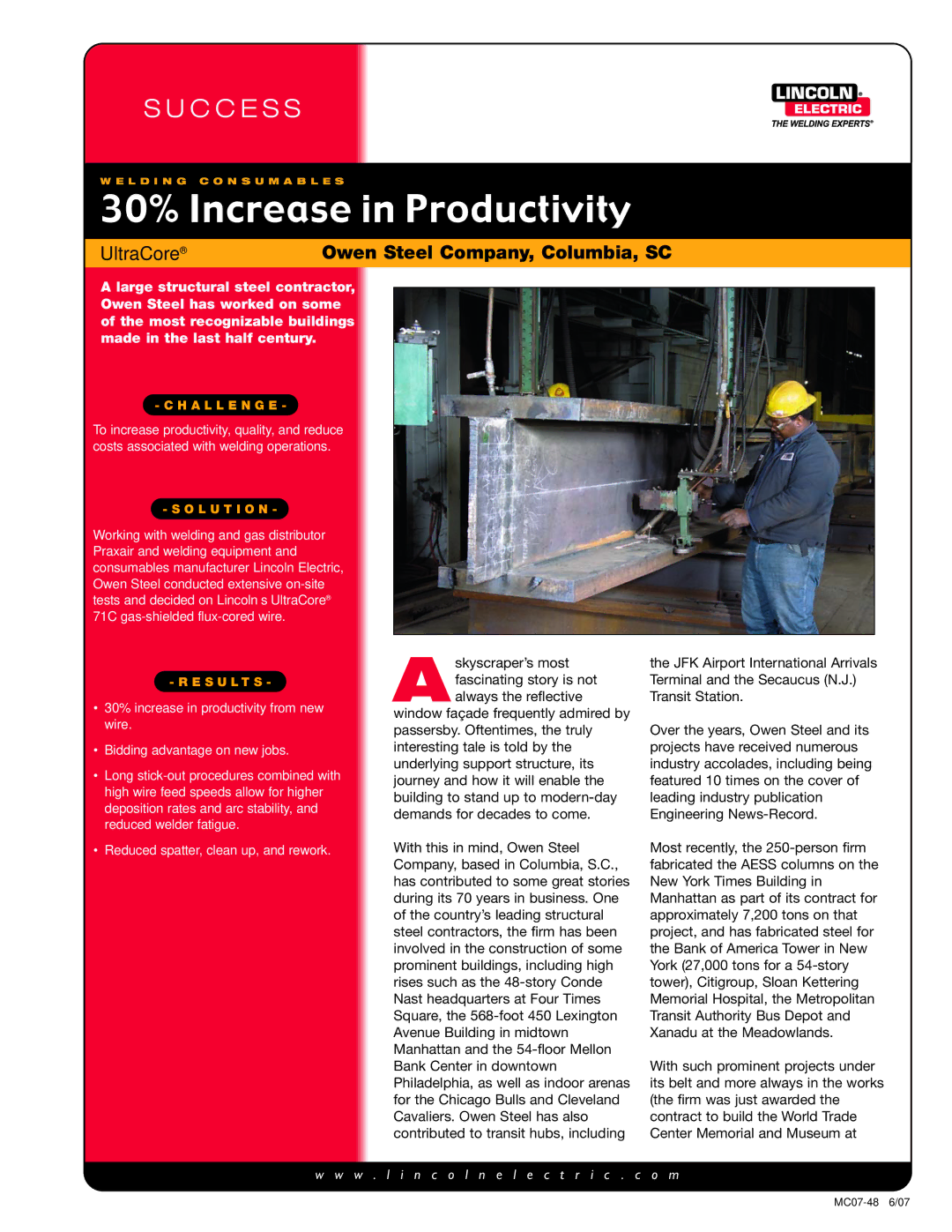

A large structural steel contractor, Owen Steel has worked on some of the most recognizable buildings made in the last half century.

- C H A L L E N G E -

To increase productivity, quality, and reduce costs associated with welding operations.

- S O L U T I O N -

Working with welding and gas distributor Praxair and welding equipment and consumables manufacturer Lincoln Electric, Owen Steel conducted extensive

tests and decided on Lincoln7s UltraCore ® 71C

- R E S U L T S -

•30% increase in productivity from new wire.

•Bidding advantage on new jobs.

•Long

•Reduced spatter, clean up, and rework.

Askyscraper’s most fascinating story is not always the reflective

window façade frequently admired by passersby. Oftentimes, the truly interesting tale is told by the underlying support structure, its journey and how it will enable the building to stand up to

With this in mind, Owen Steel Company, based in Columbia, S.C., has contributed to some great stories during its 70 years in business. One of the country’s leading structural steel contractors, the firm has been involved in the construction of some prominent buildings, including high rises such as the

the JFK Airport International Arrivals

Terminal and the Secaucus (N.J.)

Transit Station.

Over the years, Owen Steel and its projects have received numerous industry accolades, including being featured 10 times on the cover of leading industry publication Engineering

Most recently, the

With such prominent projects under its belt and more always in the works (the firm was just awarded the contract to build the World Trade Center Memorial and Museum at

w w w . l i n c o l n e l e c t r i c . c o m