| OPERATION |

| ||

|

|

|

|

|

FAN CONTROL

The fan is designed to come on automatically when a weld arc is established. The fan will stay on for a mini- mum of 6 minutes after the weld arc is terminated. The fan will also stay on when the machine’s welding and feeding are disabled during thermostatic over temperature protection. (See Welding Thermal Overload Protection)

INPUT LINE VOLTAGE PROTECTION

High Line Voltage — If the line voltage exceeds 125% of rated input voltage, the output will be reduced to the lower level to protect voltage rating of the capacitor bank.

Low Line Voltage — You may not be able to get maximum output from the machine if the line voltage is less than rated input. The unit will continue to weld, but the output may be less than what is set.

WIRE FEED OVERLOAD

PROTECTION

The PM 255 has solid state overload protection of the wire drive motor. If the motor becomes overloaded, the protection circuitry turns off the wire feed speed and gas solenoid. Check for proper size tip, liner, and drive rolls, for any obstructions or bends in the gun cable, and any other factors that would impede the wire feeding. to resume welding, simply pull the trig- ger. There is no circuit breaker to reset, as the protec- tion is done with reliable solid state electronics.

WELDING THERMAL OVERLOAD PROTECTION

The PM 255 has

OVERCURRENT PROTECTION

The machine will automatically reduce the output if the load on the machine exceeds 300 to 320 amperes. This protects the welding power SCR’s from exces- sive short circuit currents and from exceeding their temperature rating before the thermostats can react.

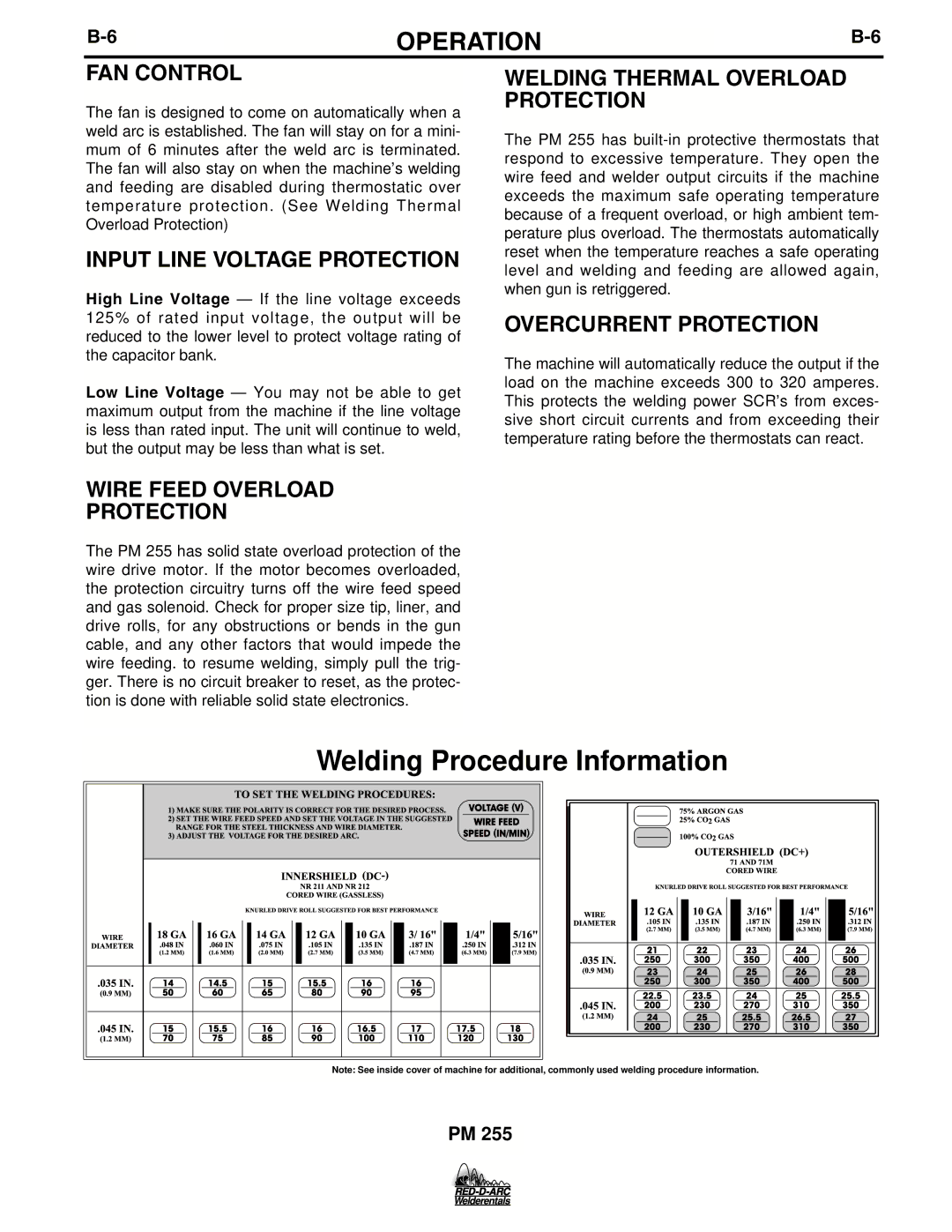

Welding Procedure Information

Note: See inside cover of machine for additional, commonly used welding procedure information.

PM 255