MAINTENANCE |

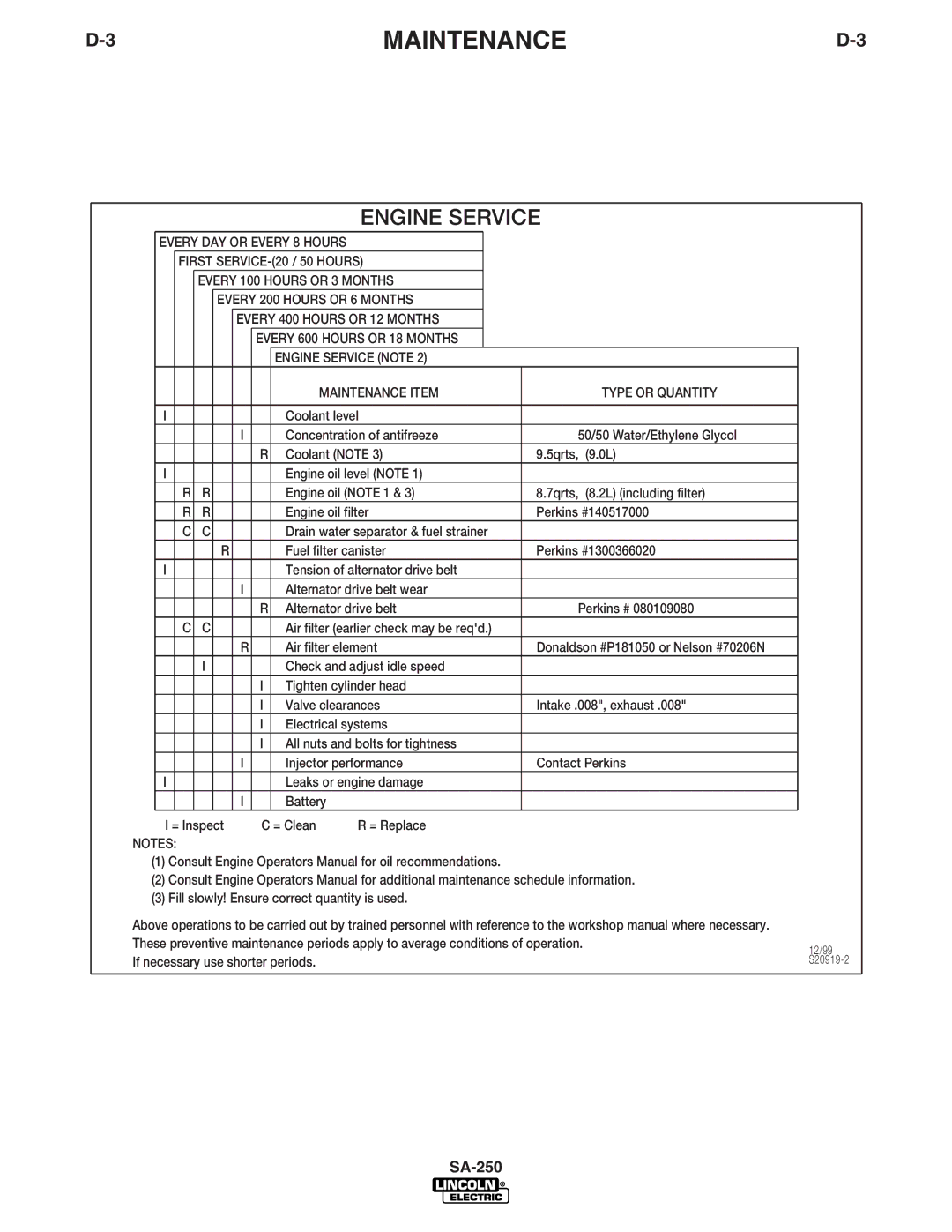

ENGINE SERVICE

| EVERY DAY OR EVERY 8 HOURS |

|

|

|

|

| ||||||

|

| FIRST |

|

|

|

| ||||||

|

|

| EVERY 100 HOURS OR 3 MONTHS |

|

|

|

| |||||

|

|

|

| EVERY 200 HOURS OR 6 MONTHS |

|

|

|

| ||||

|

|

|

|

| EVERY 400 HOURS OR 12 MONTHS |

|

|

|

| |||

|

|

|

|

|

| EVERY 600 HOURS OR 18 MONTHS |

|

|

|

| ||

|

|

|

|

|

|

| ENGINE SERVICE (NOTE 2) |

|

|

| ||

|

|

|

|

|

|

| MAINTENANCE ITEM |

| TYPE OR QUANTITY |

| ||

|

|

|

|

|

|

|

|

|

|

|

| |

| I |

|

|

|

|

| Coolant level |

|

|

| ||

|

|

|

|

| I |

| Concentration of antifreeze | 50/50 Water/Ethylene Glycol |

| |||

|

|

|

|

|

| R | Coolant (NOTE 3) | 9.5qrts, | (9.0L) |

| ||

| I |

|

|

|

|

| Engine oil level (NOTE 1) |

|

|

| ||

|

| R | R |

|

|

| Engine oil (NOTE 1 & 3) | 8.7qrts, | (8.2L) (including filter) |

| ||

|

| R | R |

|

|

| Engine oil filter | Perkins #140517000 |

| |||

|

| C | C |

|

|

| Drain water separator & fuel strainer |

|

|

| ||

|

|

|

| R |

|

| Fuel filter canister | Perkins #1300366020 |

| |||

| I |

|

|

|

|

| Tension of alternator drive belt |

|

|

| ||

|

|

|

|

| I |

| Alternator drive belt wear |

|

|

| ||

|

|

|

|

|

| R | Alternator drive belt | Perkins # 080109080 |

| |||

|

| C | C |

|

|

| Air filter (earlier check may be req'd.) |

|

|

| ||

|

|

|

|

| R |

| Air filter element | Donaldson #P181050 or Nelson #70206N |

| |||

|

|

| I |

|

|

| Check and adjust idle speed |

|

|

| ||

|

|

|

|

|

| I | Tighten cylinder head |

|

|

| ||

|

|

|

|

|

| I | Valve clearances | Intake .008", exhaust .008" |

| |||

|

|

|

|

|

| I | Electrical systems |

|

|

| ||

|

|

|

|

|

| I | All nuts and bolts for tightness |

|

|

| ||

|

|

|

|

| I |

| Injector performance | Contact Perkins |

| |||

| I |

|

|

|

|

| Leaks or engine damage |

|

|

| ||

|

|

|

|

| I |

| Battery |

|

|

|

|

|

| I = Inspect |

| C = Clean | R = Replace |

|

|

| |||||

NOTES: |

|

|

|

|

|

|

|

|

|

| ||

(1) Consult Engine Operators Manual for oil recommendations. |

|

|

| |||||||||

(2) Consult Engine Operators Manual for additional maintenance schedule information. | ||||||||||||

(3) Fill slowly! Ensure correct quantity is used. |

|

|

| |||||||||

Above operations to be carried out by trained personnel with reference to the workshop manual where necessary. | ||||||||||||

These preventive maintenance periods apply to average conditions of operation. | 12/99 | |||||||||||

If necessary use shorter periods. |

|

|

| |||||||||

|

|

|

| |||||||||