SVM176-A specifications

The Lincoln Electric SVM176-A is a robust and versatile semiautomatic wire feeder designed to cater to a wide range of welding applications. Known for its reliability and ease of use, the SVM176-A is particularly favored in both industrial and construction settings, where efficiency and performance are paramount.One of the standout features of the SVM176-A is its compact design. This relatively lightweight unit is easy to transport and can fit into tight spaces, making it an ideal choice for mobile applications or projects that require more maneuverability. The unit's construction is durable and built to withstand the rigors of demanding work environments, ensuring longevity and consistent performance.

The SVM176-A supports various welding processes, including MIG (Metal Inert Gas) and flux-cored arc welding, providing versatility for different materials and thicknesses. This adaptability is enhanced by its ability to accommodate a variety of wire sizes, allowing users to select the ideal wire type for their specific project requirements. The equipment also features adjustable wire feed speed, helping to ensure optimal weld quality by allowing operators to tailor their settings based on the needs of the job.

Innovative technologies in the SVM176-A contribute to its performance. The unit is equipped with a digitally controlled microprocessor that streamlines operations, providing enhanced control over welding parameters. This advanced technology enables users to achieve precise welds consistently, minimizing the risk of defects and improving overall efficiency.

Another remarkable characteristic of the SVM176-A is its user-friendly interface. The unit features easy-to-read displays and intuitive controls, enabling operators to make quick adjustments without having to consult an extensive manual. This is particularly beneficial in fast-paced work environments where time is of the essence.

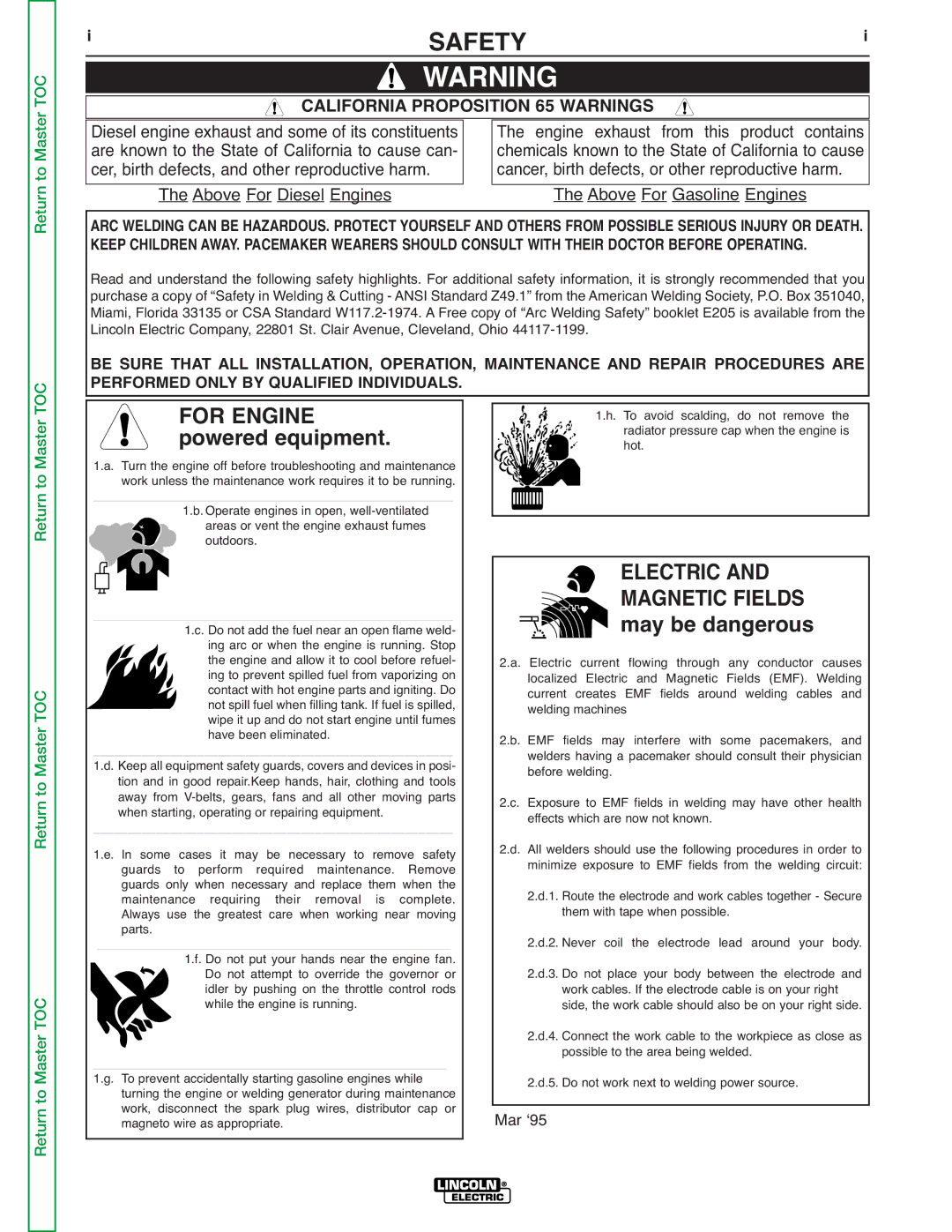

Furthermore, the Lincoln Electric SVM176-A boasts a range of safety features, including thermal overload protection and a sturdy casing, which safeguard both the equipment and the operator. With these characteristics combined, the SVM176-A stands out as a preferred choice for professional welders seeking reliability, versatility, and operational excellence in their equipment. This exceptional wire feeder continues to uphold Lincoln Electric's commitment to quality and performance in welding technology.