Invertec® V205-T AC/DC TIG WELDERS

Output

For TIG and Stick Welding

The Invertec®

AC

DC

Input

1

PHASE

50

60

Processes | Hz |

|

Stick, TIG

Advantage Lincoln

Precision Arc Performance

![]()

![]() • Added Stick Crisp Mode for exceptional Fleetweld® 5P and 5P+ (E6010) Performance.

• Added Stick Crisp Mode for exceptional Fleetweld® 5P and 5P+ (E6010) Performance.

![]()

![]() • Improved TIG starting. Now starts

• Improved TIG starting. Now starts

![]()

![]() • Adjustable DC strike mode – Allows adjustment of a hotter or colder start depending on the tungsten diameter.

• Adjustable DC strike mode – Allows adjustment of a hotter or colder start depending on the tungsten diameter.

•AC/DC inverter for TIG with advanced inverter technology to optimize arc performance.

•Adjustable AC output frequency allows the operator to focus the arc minimizing the heat affected zone.

•Extended AC Balance Control helps maintain a pointed tungsten to direct the arc in the weld joint.

•Selectable waveshapes – Square wave for fast travel speeds and

excellent puddle control, sine wave for a traditional softer sounding arc, ![]()

![]() triangular wave to reduce the heat input into the weld at low amperages.

triangular wave to reduce the heat input into the weld at low amperages.

•200 amps @ 40% duty cycle is the highest output rating in this machine class.

•

•Weighs in at a mere 38 lbs. (17.3 kg) making it easy to carry around the shop or job site.

Simple Controls

•Full featured TIG control – up to 11 variable – including pulse, upslope, downslope and balance control.

•Easy to read sequence diagram with LEDs displays selected parameter for easy setting with a single knob.

Outstanding Quality

•

•High quality stick welding with such popular Lincoln® electrodes as Fleetweld® 5P, 35, 37, 180 and Excalibur® 7018.

Professional Features

![]()

![]() • Voltage Reduction Device (VRD). When enabled from the set up menu reduces the open circuit voltage in STICK mode for use in electrically hazardous conditions or when the use of a VRD is required.

• Voltage Reduction Device (VRD). When enabled from the set up menu reduces the open circuit voltage in STICK mode for use in electrically hazardous conditions or when the use of a VRD is required.

![]()

![]() • Newly designed using the latest power electronic technology for improved reliability.

• Newly designed using the latest power electronic technology for improved reliability.

•CSA C/US Certified.

•

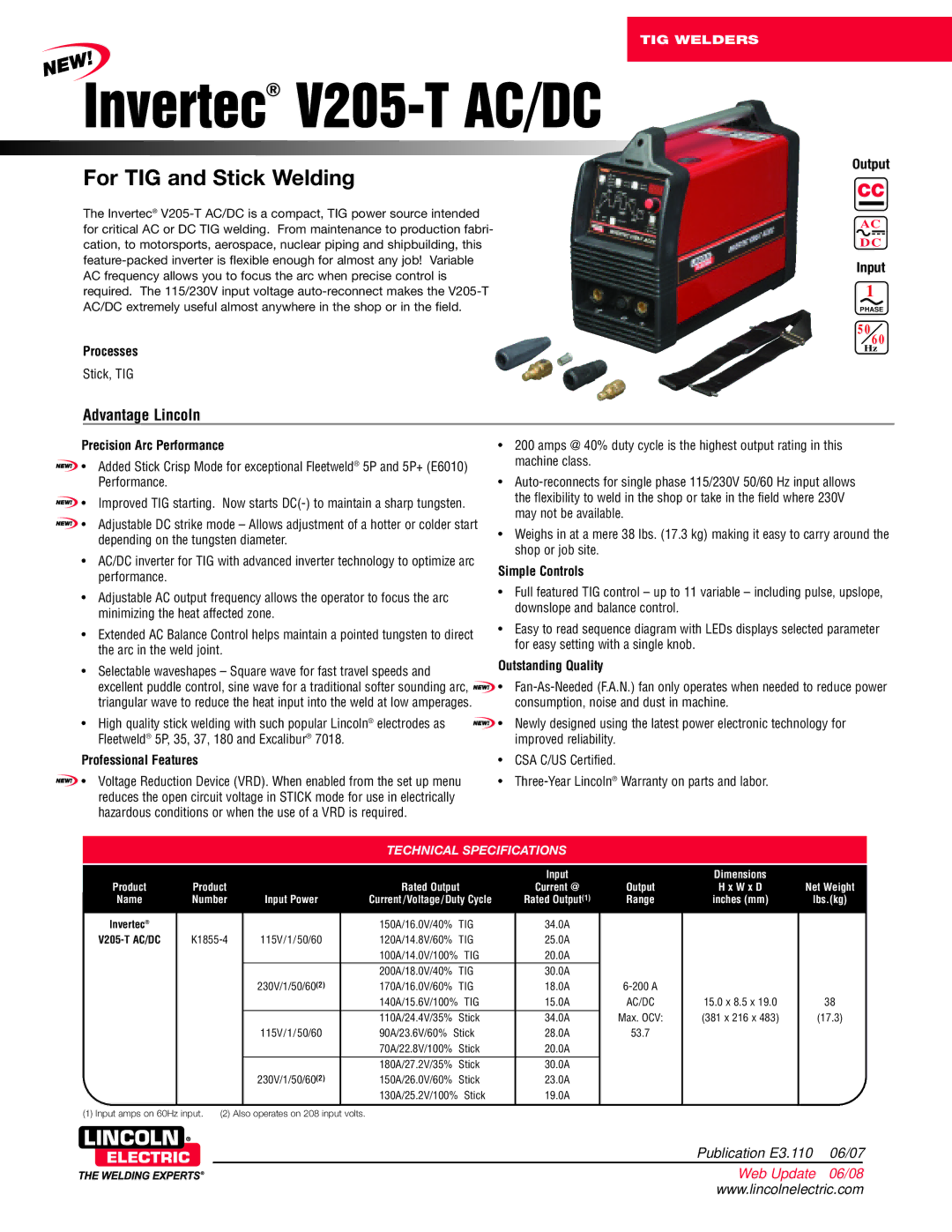

TECHNICAL SPECIFICATIONS

|

|

|

| Input |

| Dimensions |

|

Product | Product |

| Rated Output | Current @ | Output | H x W x D | Net Weight |

Name | Number | Input Power | Current/Voltage/ Duty Cycle | Rated Output(1) | Range | inches (mm) | lbs.(kg) |

|

|

|

|

|

|

|

|

Invertec®

V205-T AC/DC

| 150A/16.0V/40% | TIG | 34.0A |

115V/1/50/60 | 120A/14.8V/60% | TIG | 25.0A |

| 100A/14.0V/100% | TIG | 20.0A |

| 200A/18.0V/40% | TIG | 30.0A |

230V/1/50/60(2) | 170A/16.0V/60% | TIG | 18.0A |

| 140A/15.6V/100% | TIG | 15.0A |

|

|

|

|

| 110A/24.4V/35% | Stick | 34.0A |

115V/1/50/60 | 90A/23.6V/60% Stick | 28.0A | |

| 70A/22.8V/100% | Stick | 20.0A |

| 180A/27.2V/35% | Stick | 30.0A |

230V/1/50/60(2) | 150A/26.0V/60% | Stick | 23.0A |

| 130A/25.2V/100% | Stick | 19.0A |

AC/DC

Max. OCV:

53.7

15.0x 8.5 x 19.0

(381 x 216 x 483)

38

(17.3)

(1) Input amps on 60Hz input. | (2) Also operates on 208 input volts. |

P ublication E 3.110 | 06/07 |

W | eb Update | 06/08 |

www | .lincolnelectric.com | |