V450-PRO specifications

The Lincoln Electric V450-PRO is a cutting-edge multi-process welding machine designed to meet the needs of professionals in various industries, including fabrication, manufacturing, and construction. This versatile system is suitable for MIG, TIG, and stick welding, providing users with the flexibility to tackle a wide range of welding applications.One of the standout features of the V450-PRO is its advanced inverter technology. This innovation allows for a lighter and more compact machine compared to traditional welding setups, without sacrificing performance or reliability. The inverter technology also enables the V450-PRO to provide a smooth, stable arc, which is essential for producing high-quality welds.

The machine is equipped with a high output capacity, delivering up to 450 amps of welding power, which makes it suitable for heavy-duty applications. The durable construction and high-performance capabilities ensure the V450-PRO can handle thick materials with ease, making it a top choice for demanding projects.

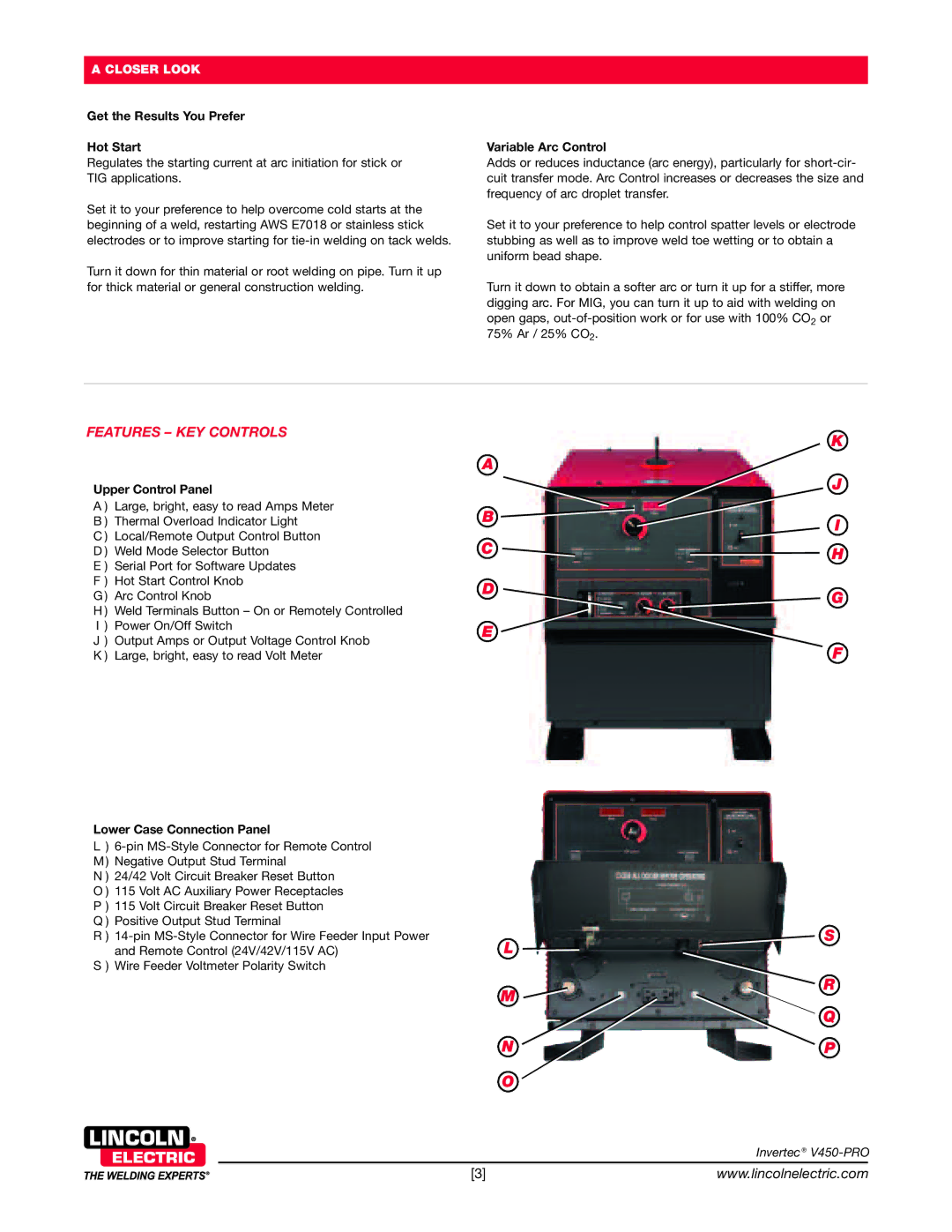

Another notable characteristic of the V450-PRO is its user-friendly interface. The digital display provides real-time feedback on welding parameters, allowing operators to make quick adjustments for optimal performance. This feature aids in reducing setup time and improving overall productivity. Additionally, the intuitive control panel is designed to be easy to navigate, making it accessible for both experienced welders and those new to the field.

The V450-PRO also incorporates advanced features such as synergic control, where the machine automatically adjusts the voltage and wire feed speed according to the selected material and thickness. This results in better consistency in weld quality and helps prevent common issues such as burn-through or insufficient penetration.

Furthermore, the V450-PRO supports a wide range of wire diameters and types, including solid, flux-cored, and aluminum wire, enhancing its versatility for different welding tasks. As a result, users can switch between various welding processes seamlessly without needing multiple machines.

Safety is paramount with the V450-PRO, which includes features like over-temperature protection and circuit breakers to safeguard both the operator and the machine.

In conclusion, the Lincoln Electric V450-PRO is a powerful, versatile, and user-friendly welding machine that elevates the welding experience. With its advanced technologies and robust features, it stands out as an excellent choice for professionals looking to achieve exceptional results in their welding projects.