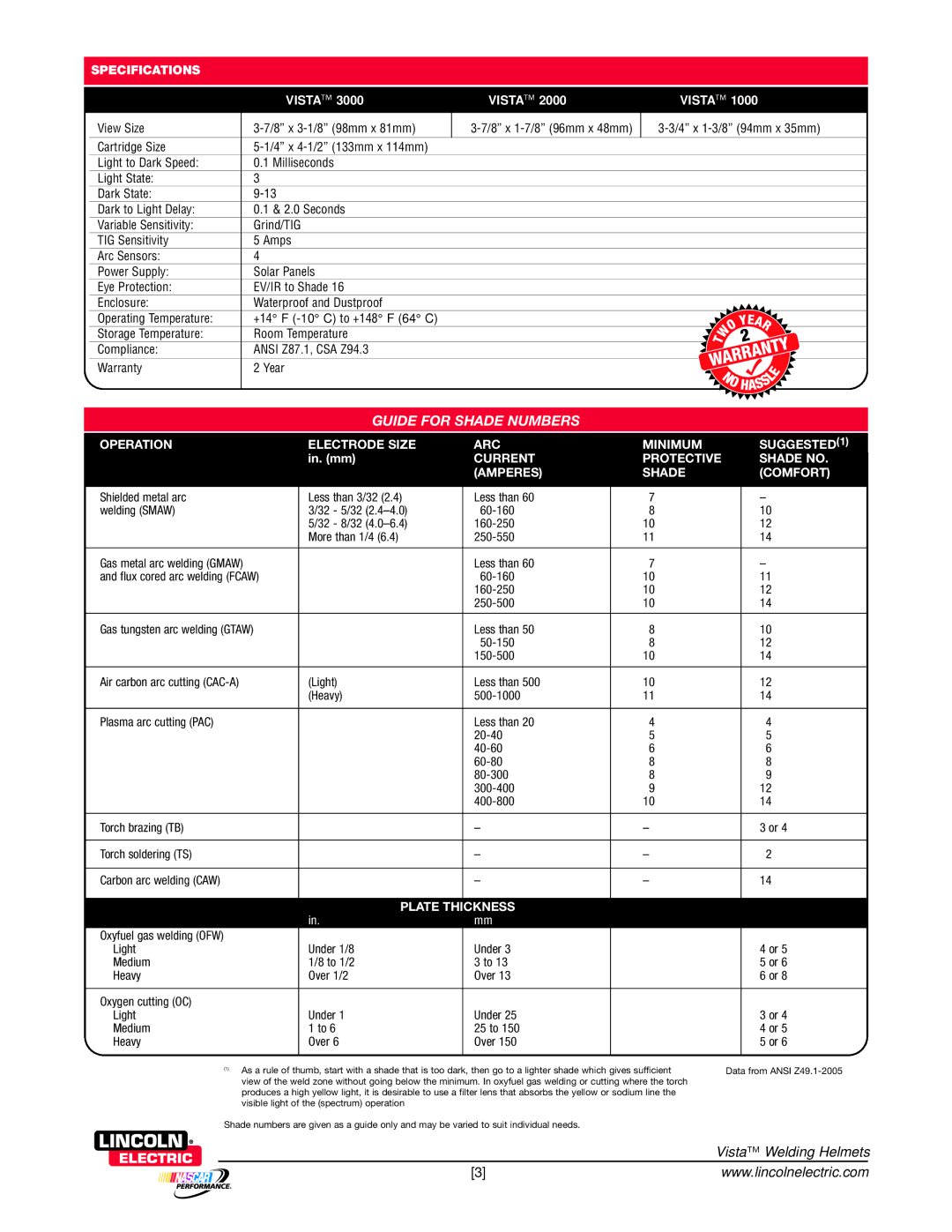

SPECIFICATIONS

|

| VISTA | ™ 3000 | VISTA ™ 2000 | VISTA ™ 1000 | |

|

|

|

|

|

|

|

| View Size | |||||

|

|

|

|

|

| |

| Cartridge Size |

|

|

| ||

| Light to Dark Speed: | 0.1 Milliseconds |

|

|

| |

| Light State: | 3 |

|

|

|

|

| Dark State: |

|

|

|

| |

| Dark to Light Delay: | 0.1 & 2.0 Seconds |

|

|

| |

| Variable Sensitivity: | Grind/TIG |

|

|

|

|

| TIG Sensitivity | 5 Amps |

|

|

|

|

| Arc Sensors: | 4 |

|

|

|

|

| Power Supply: | Solar Panels |

|

|

|

|

| Eye Protection: | EV/IR to Shade 16 |

|

|

| |

| Enclosure: | Waterproof and Dustproof |

|

|

| |

| Operating Temperature: | +14° F | to +148° F (64° C) |

|

|

|

| Storage Temperature: | Room Temperature |

|

|

| |

| Compliance: | ANSI Z87.1, CSA Z94.3 |

|

|

| |

| Warranty | 2 Year |

|

|

|

|

|

|

|

|

|

|

|

GUIDE FOR SHADE NUMBERS

| OPERATION | ELECTRODE SIZE | ARC | MINIMUM | SUGGESTED(1) |

|

| in. (mm) | CURRENT | PROTECTIVE | SHADE NO. |

|

|

| (AMPERES) | SHADE | (COMFORT) |

|

|

|

|

|

|

| Shielded metal arc | Less than 3/32 (2.4) | Less than 60 | 7 | – |

| welding (SMAW) | 3/32 - 5/32 | 8 | 10 | |

|

| 5/32 - 8/32 | 10 | 12 | |

|

| More than 1/4 (6.4) | 11 | 14 | |

|

|

|

|

|

|

| Gas metal arc welding (GMAW) |

| Less than 60 | 7 | – |

| and flux cored arc welding (FCAW) |

| 10 | 11 | |

|

|

| 10 | 12 | |

|

|

| 10 | 14 | |

|

|

|

|

|

|

| Gas tungsten arc welding (GTAW) |

| Less than 50 | 8 | 10 |

|

|

| 8 | 12 | |

|

|

| 10 | 14 | |

|

|

|

|

|

|

| Air carbon arc cutting | (Light) | Less than 500 | 10 | 12 |

|

| (Heavy) | 11 | 14 | |

|

|

|

|

|

|

| Plasma arc cutting (PAC) |

| Less than 20 | 4 | 4 |

|

|

| 5 | 5 | |

|

|

| 6 | 6 | |

|

|

| 8 | 8 | |

|

|

| 8 | 9 | |

|

|

| 9 | 12 | |

|

|

| 10 | 14 | |

|

|

|

|

|

|

| Torch brazing (TB) |

| – | – | 3 or 4 |

|

|

|

|

|

|

| Torch soldering (TS) |

| – | – | 2 |

|

|

|

|

|

|

| Carbon arc welding (CAW) |

| – | – | 14 |

|

|

|

|

|

|

|

| PLATE THICKNESS |

|

| |

|

| in. | mm |

|

|

| Oxyfuel gas welding (OFW) |

|

|

|

|

| Light | Under 1/8 | Under 3 |

| 4 or 5 |

| Medium | 1/8 to 1/2 | 3 to 13 |

| 5 or 6 |

| Heavy | Over 1/2 | Over 13 |

| 6 or 8 |

|

|

|

|

|

|

| Oxygen cutting (OC) |

|

|

|

|

| Light | Under 1 | Under 25 |

| 3 or 4 |

| Medium | 1 to 6 | 25 to 150 |

| 4 or 5 |

| Heavy | Over 6 | Over 150 |

| 5 or 6 |

|

|

|

|

|

|

(1) | As a rule of thumb, start with a shade that is too dark, then go to a lighter shade which gives sufficient | Data from ANSI |

|

|

view of the weld zone without going below the minimum. In oxyfuel gas welding or cutting where the torch produces a high yellow light, it is desirable to use a filter lens that absorbs the yellow or sodium line the visible light of the (spectrum) operation

Shade numbers are given as a guide only and may be varied to suit individual needs.

Vista™ Welding Helmets

[3] | www.lincolnelectric.com |