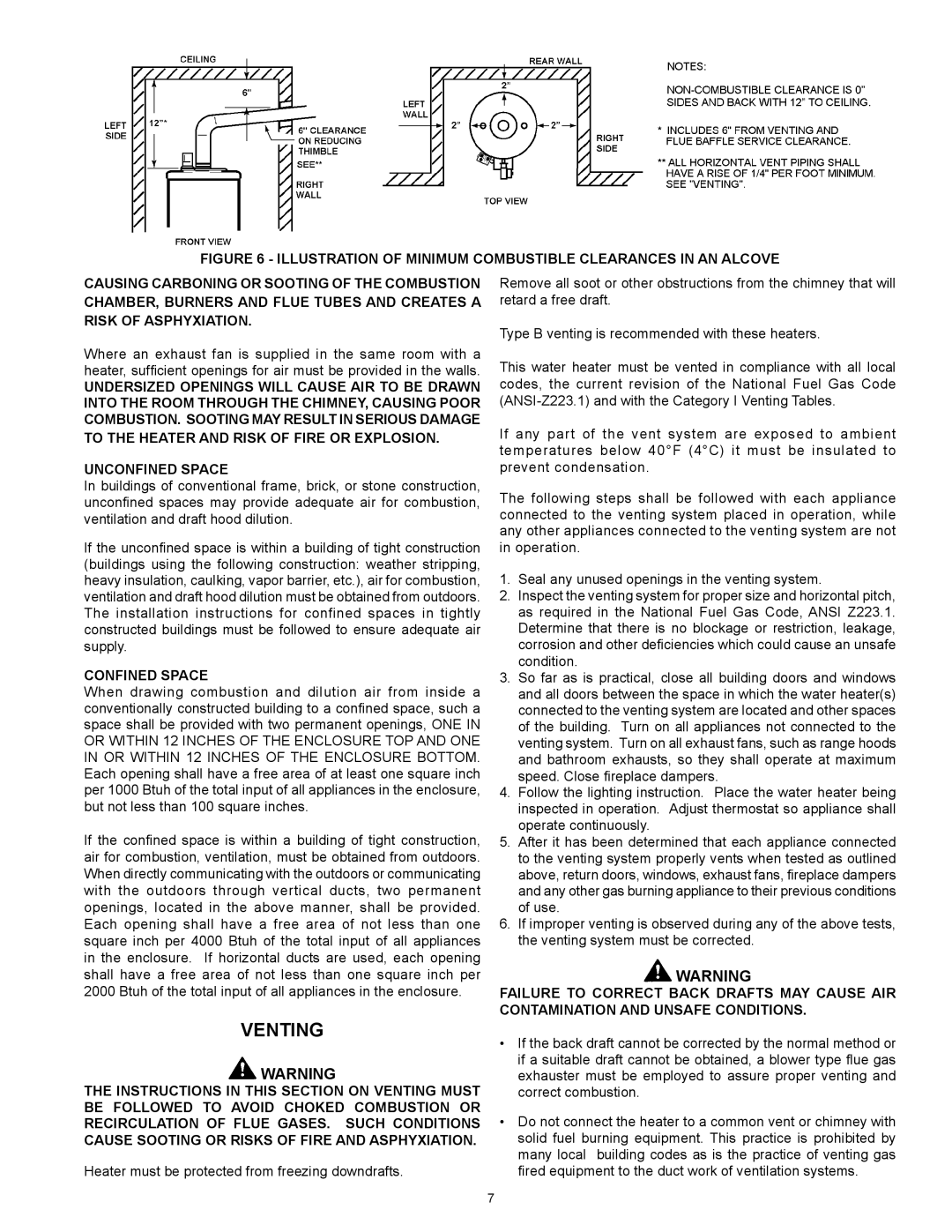

FIGURE 6 - ILLUSTRATION OF MINIMUM COMBUSTIBLE CLEARANCES IN AN ALCOVE

CAUSING CARBONING OR SOOTING OF THE COMBUSTION CHAMBER, BURNERS AND FLUE TUBES AND CREATES A RISK OF ASPHYXIATION.

Where an exhaust fan is supplied in the same room with a heater, sufficient openings for air must be provided in the walls.

UNDERSIZED OPENINGS WILL CAUSE AIR TO BE DRAWN INTO THE ROOM THROUGH THE CHIMNEY, CAUSING POOR COMBUSTION. SOOTING MAY RESULT IN SERIOUS DAMAGE TO THE HEATER AND RISK OF FIRE OR EXPLOSION.

UNCONFINED SPACE

In buildings of conventional frame, brick, or stone construction, unconfined spaces may provide adequate air for combustion, ventilation and draft hood dilution.

If the unconfined space is within a building of tight construction (buildings using the following construction: weather stripping, heavy insulation, caulking, vapor barrier, etc.), air for combustion, ventilation and draft hood dilution must be obtained from outdoors. The installation instructions for confined spaces in tightly constructed buildings must be followed to ensure adequate air supply.

CONFINED SPACE

When drawing combustion and dilution air from inside a conventionally constructed building to a confined space, such a space shall be provided with two permanent openings, ONE IN OR WITHIN 12 INCHES OF THE ENCLOSURE TOP AND ONE IN OR WITHIN 12 INCHES OF THE ENCLOSURE BOTTOM. Each opening shall have a free area of at least one square inch per 1000 Btuh of the total input of all appliances in the enclosure, but not less than 100 square inches.

If the confined space is within a building of tight construction, air for combustion, ventilation, must be obtained from outdoors. When directly communicating with the outdoors or communicating with the outdoors through vertical ducts, two permanent openings, located in the above manner, shall be provided. Each opening shall have a free area of not less than one square inch per 4000 Btuh of the total input of all appliances in the enclosure. If horizontal ducts are used, each opening shall have a free area of not less than one square inch per 2000 Btuh of the total input of all appliances in the enclosure.

VENTING

![]() WARNING

WARNING

THE INSTRUCTIONS IN THIS SECTION ON VENTING MUST BE FOLLOWED TO AVOID CHOKED COMBUSTION OR RECIRCULATION OF FLUE GASES. SUCH CONDITIONS CAUSE SOOTING OR RISKS OF FIRE AND ASPHYXIATION.

Heater must be protected from freezing downdrafts.

Remove all soot or other obstructions from the chimney that will retard a free draft.

Type B venting is recommended with these heaters.

This water heater must be vented in compliance with all local codes, the current revision of the National Fuel Gas Code

If any part of the vent system are exposed to ambient temperatures below 40°F (4°C) it must be insulated to prevent condensation.

The following steps shall be followed with each appliance connected to the venting system placed in operation, while any other appliances connected to the venting system are not in operation.

1.Seal any unused openings in the venting system.

2.Inspect the venting system for proper size and horizontal pitch, as required in the National Fuel Gas Code, ANSI Z223.1. Determine that there is no blockage or restriction, leakage, corrosion and other deficiencies which could cause an unsafe condition.

3.So far as is practical, close all building doors and windows and all doors between the space in which the water heater(s) connected to the venting system are located and other spaces of the building. Turn on all appliances not connected to the venting system. Turn on all exhaust fans, such as range hoods and bathroom exhausts, so they shall operate at maximum speed. Close fireplace dampers.

4.Follow the lighting instruction. Place the water heater being inspected in operation. Adjust thermostat so appliance shall operate continuously.

5.After it has been determined that each appliance connected to the venting system properly vents when tested as outlined above, return doors, windows, exhaust fans, fireplace dampers and any other gas burning appliance to their previous conditions of use.

6.If improper venting is observed during any of the above tests, the venting system must be corrected.

![]() WARNING

WARNING

FAILURE TO CORRECT BACK DRAFTS MAY CAUSE AIR CONTAMINATION AND UNSAFE CONDITIONS.

•If the back draft cannot be corrected by the normal method or if a suitable draft cannot be obtained, a blower type flue gas exhauster must be employed to assure proper venting and correct combustion.

•Do not connect the heater to a common vent or chimney with solid fuel burning equipment. This practice is prohibited by many local building codes as is the practice of venting gas fired equipment to the duct work of ventilation systems.

7