707 specifications

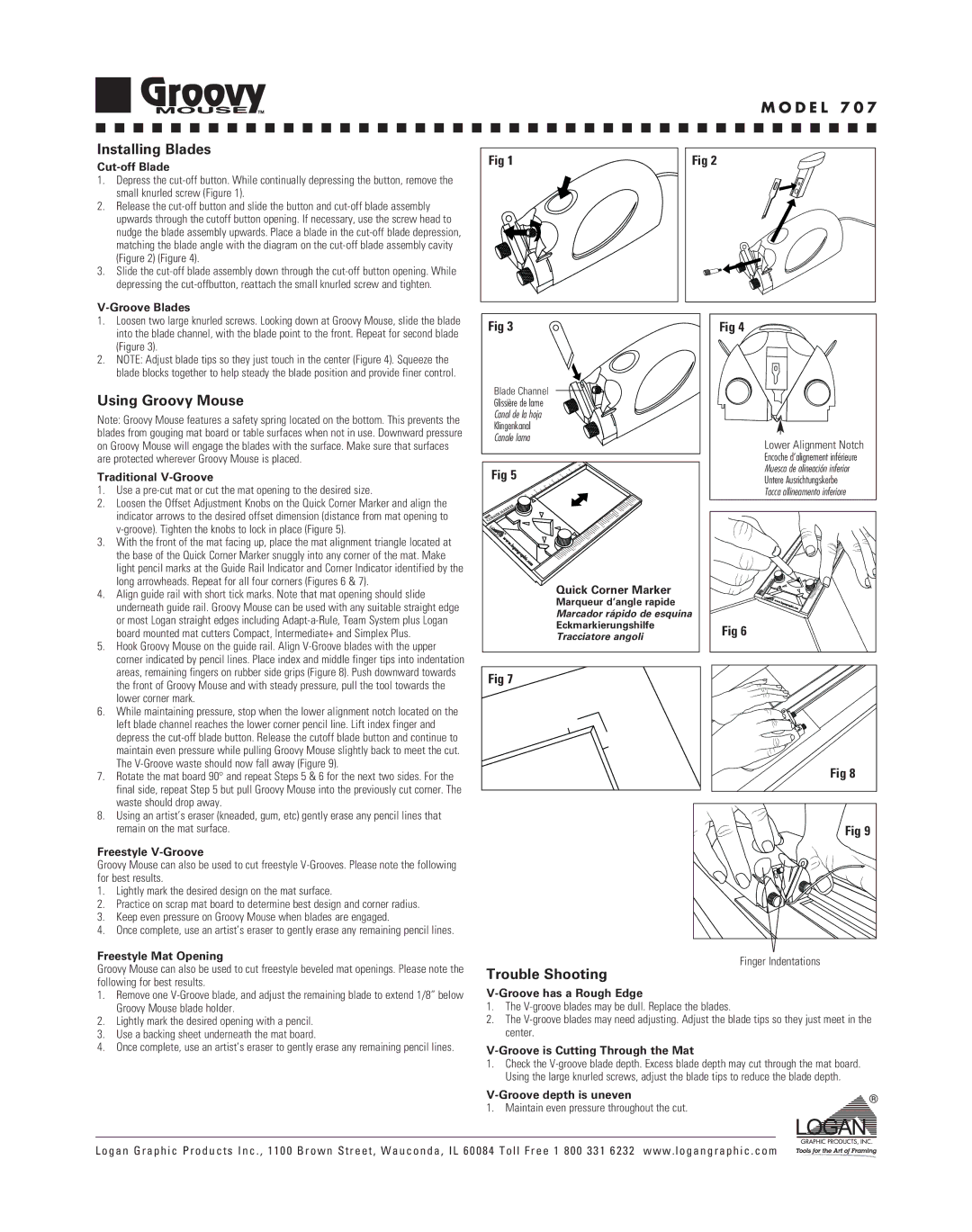

Logan Graphic Products 707 is a premier professional cutting tool designed for artists, designers, and framers. It encapsulates innovative technology and practical functionality, making it a go-to choice for precision cutting in various applications such as mat cutting, mounting artworks, and more.One of the standout features of the Logan 707 is its dual blade system. This ingenious design allows users to switch between straight and bevel cuts effortlessly. The straight blade is ideal for cutting materials like mat board, while the bevel blade is perfect for creating angled edges that provide a professional finish. These blades are easy to replace, ensuring that users can maintain cutting efficiency.

The Logan 707 is built with a sturdy construction, featuring a solid aluminum base that provides stability during use. This durability not only enhances the longevity of the tool but also ensures consistent performance, even when tackling thicker materials. The integrated cutting rail guides the blade along its path, promoting accuracy and reducing the risk of miscuts, which is crucial for achieving clean, precise results.

In addition to its robust build, the 707 employs innovative alignment features, allowing users to position their materials with utmost precision. The adjustable stop ensures that every cut is uniform, which is particularly beneficial for repeated cuts. Users can easily measure and mark their materials, enhancing overall efficiency and productivity.

Another significant characteristic of the Logan 707 is its versatility. It accommodates a broad range of materials, including card stocks, foam boards, and even canvas, making it suitable for various creative projects. This adaptability is a key advantage for artists and craftspeople who need a reliable tool for their diverse cutting needs.

Logan Graphic Products also places emphasis on user safety. The design incorporates safety features such as a retractable blade, which minimizes the risk of accidental cuts when the tool is not in use. This attention to safety is vital for both professional settings as well as educational environments where students are learning cutting techniques.

In summary, the Logan Graphic Products 707 is a sophisticated, versatile cutting tool that combines precision, durability, and user-friendly features. Its dual blade system, robust construction, and safety enhancements make it an ideal solution for artists, framers, and hobbyists seeking to achieve high-quality, professional-level cuts in their creative endeavors.