Trucklift | Maintenance, Troubleshooting |

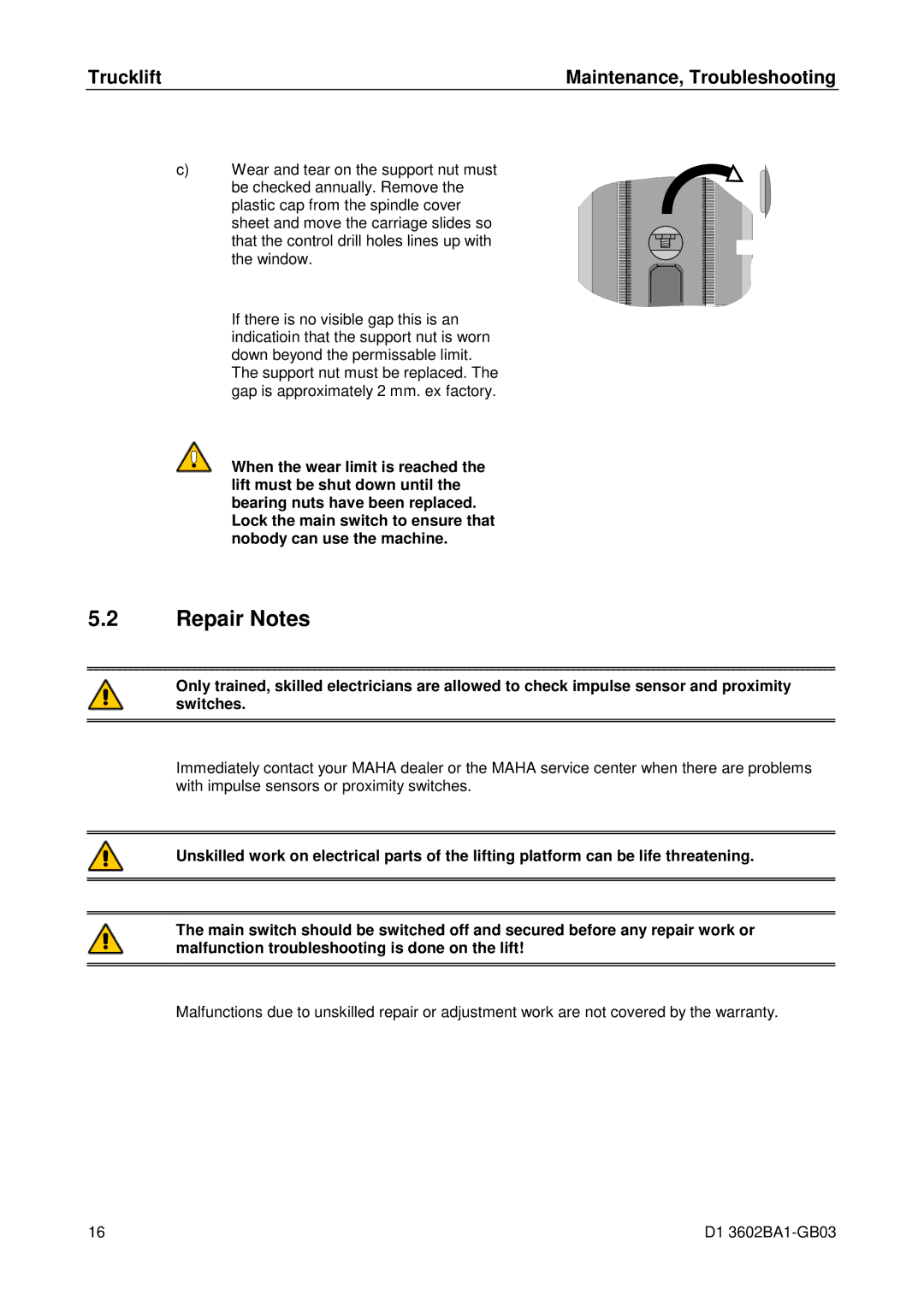

c)Wear and tear on the support nut must be checked annually. Remove the plastic cap from the spindle cover sheet and move the carriage slides so that the control drill holes lines up with the window.

If there is no visible gap this is an indicatioin that the support nut is worn down beyond the permissable limit. The support nut must be replaced. The gap is approximately 2 mm. ex factory.

When the wear limit is reached the lift must be shut down until the bearing nuts have been replaced. Lock the main switch to ensure that nobody can use the machine.

5.2Repair Notes

Only trained, skilled electricians are allowed to check impulse sensor and proximity switches.

Immediately contact your MAHA dealer or the MAHA service center when there are problems with impulse sensors or proximity switches.

Unskilled work on electrical parts of the lifting platform can be life threatening.

The main switch should be switched off and secured before any repair work or malfunction troubleshooting is done on the lift!

Malfunctions due to unskilled repair or adjustment work are not covered by the warranty.

16 | D1 |