REPLACING OR INSTALLING PLANER BLADES

After unpluggingthe tool, you may remove the planer blades on the tool drum by un- screwing the four installation bolts with the socket wrench provided. The clamp plate comes off together with the blades.

(See Photo)

When you install new or sharpened blades, first clean out all chips or foreign matter adhering to the drum or blades. Use blades of the same dimensions and weight, or drum oscillation/vibration will result, caus- ing poor planing action and, eventually, tool breakdown.

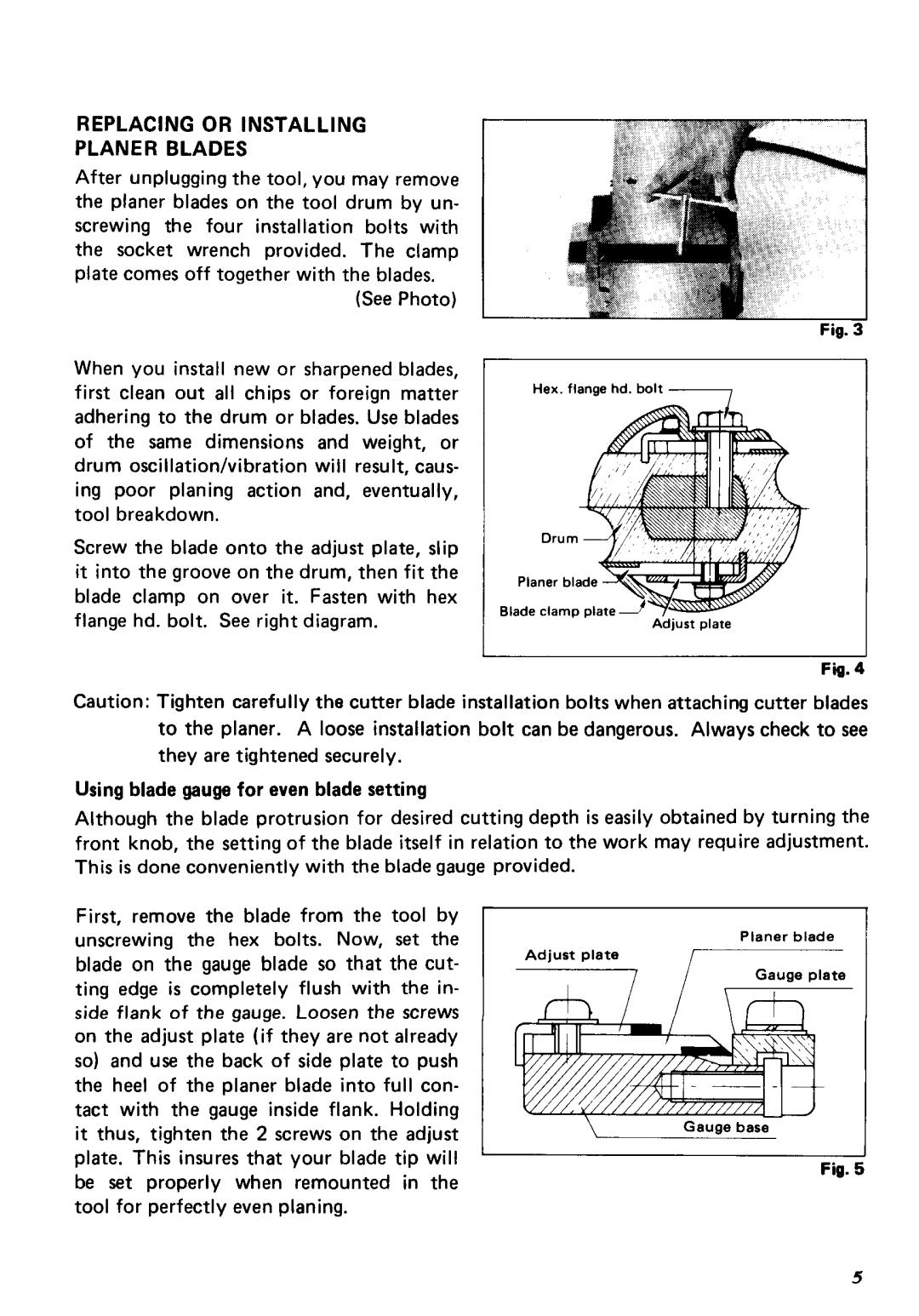

Screw the blade onto the adjust plate, slip it into the groove on the drum, then fit the blade clamp on over it. Fasten with hex flange hd. bolt. See right diagram.

Fig. 3

Hex. flange hd. bolt I

Blade clamr, Dla

Adjust plate

Fig. 4

Caution: Tighten carefully the cutter blade installation bolts when attaching cutter blades to the planer. A loose installation bolt can be dangerous. Always check to see they are tightened securely.

Using blade gauge for even blade setting

Although the blade protrusion for desired cutting depth is easily obtained by turning the front knob, the setting of the blade itself in relation to the work may require adjustment. This is done conveniently with the blade gauge provided.

First, remove the blade from the tool by |

|

| Planer blade |

unscrewing the hex bolts. Now, set the |

|

| |

blade on the gauge blade so that the cut- |

|

|

|

ting edge is completely flush with the in- |

|

|

|

side flank of the gauge. Loosen the screws |

|

|

|

on the adjust plate (if they are not already |

|

|

|

so) and use the back of side plate to push |

|

|

|

the heel of the planer blade into full con- |

|

|

|

tact with the gauge inside flank. Holding | ' | \ |

|

it thus, tighten the 2 screws on the adjust | Gauge base | ||

plate. This insures that your blade tip will |

| Fig. 5 | |

be set properly when remounted in the |

|

| |

|

|

| |

tool for perfectly even planing. |

|

|

|

5