1

2

3

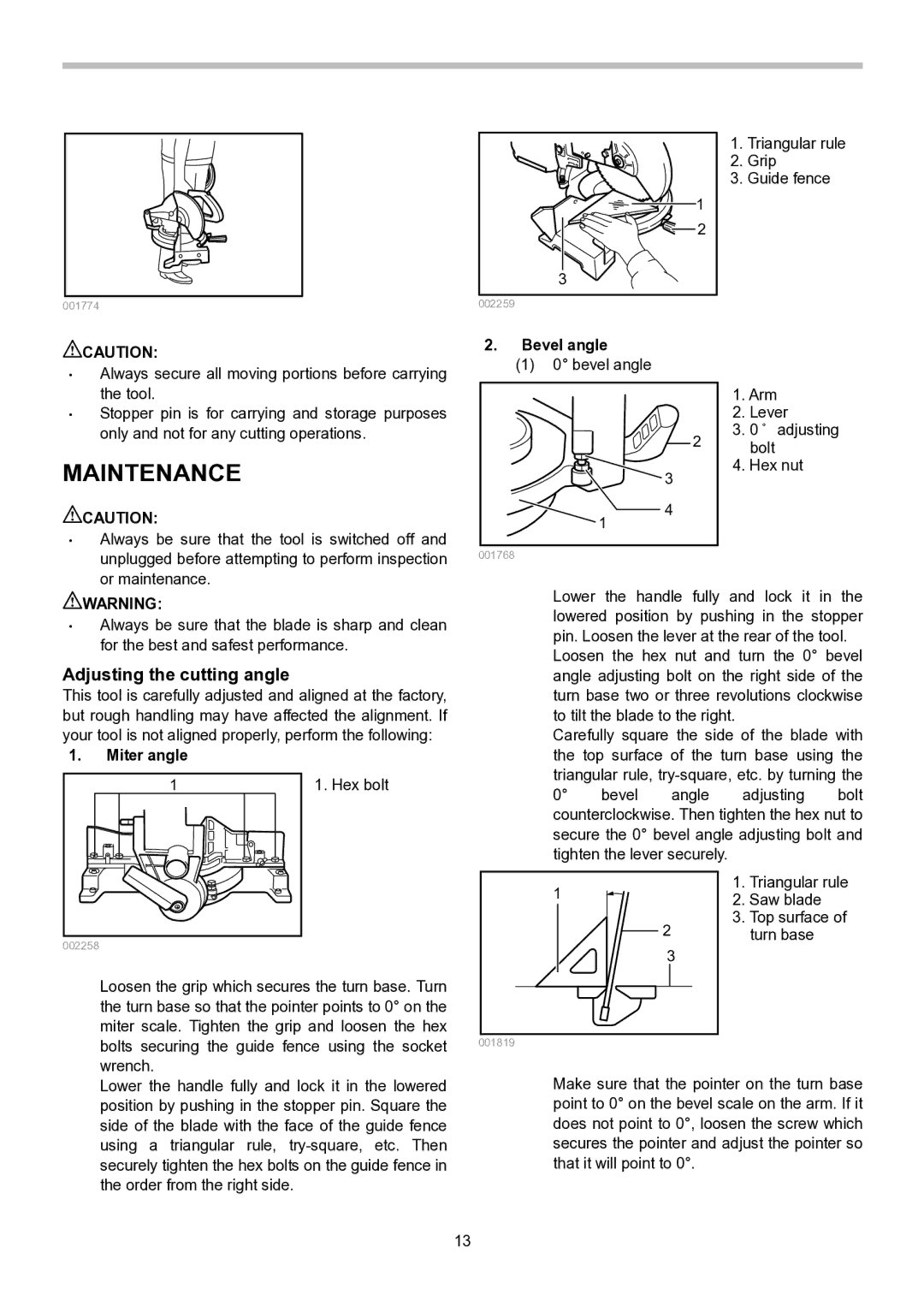

1.Triangular rule

2.Grip

3.Guide fence

001774

![]() CAUTION:

CAUTION:

•Always secure all moving portions before carrying the tool.

•Stopper pin is for carrying and storage purposes only and not for any cutting operations.

MAINTENANCE

002259

2.Bevel angle

(1)0° bevel angle

2

![]() 3

3

1.Arm

2.Lever

3.0 ゚ adjusting bolt

4.Hex nut

![]() CAUTION:

CAUTION:

•Always be sure that the tool is switched off and unplugged before attempting to perform inspection or maintenance.

1

001768

4

![]() WARNING:

WARNING:

•Always be sure that the blade is sharp and clean for the best and safest performance.

Adjusting the cutting angle

This tool is carefully adjusted and aligned at the factory, but rough handling may have affected the alignment. If your tool is not aligned properly, perform the following:

1.Miter angle

1 | 1. Hex bolt |

002258 |

|

Loosen the grip which secures the turn base. Turn the turn base so that the pointer points to 0° on the miter scale. Tighten the grip and loosen the hex bolts securing the guide fence using the socket wrench.

Lower the handle fully and lock it in the lowered position by pushing in the stopper pin. Square the side of the blade with the face of the guide fence using a triangular rule,

Lower the handle fully and lock it in the lowered position by pushing in the stopper pin. Loosen the lever at the rear of the tool.

Loosen the hex nut and turn the 0° bevel angle adjusting bolt on the right side of the turn base two or three revolutions clockwise to tilt the blade to the right.

Carefully square the side of the blade with the top surface of the turn base using the triangular rule,

0° bevel angle adjusting bolt counterclockwise. Then tighten the hex nut to secure the 0° bevel angle adjusting bolt and tighten the lever securely.

1 |

|

| 1. | Triangular rule | ||||

|

|

|

|

| 2. Saw blade | |||

|

|

|

| 3. | Top surface of | |||

|

|

|

| 2 |

|

| turn base | |

|

|

|

|

|

| |||

|

|

| 3 |

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

001819

Make sure that the pointer on the turn base point to 0° on the bevel scale on the arm. If it does not point to 0°, loosen the screw which secures the pointer and adjust the pointer so that it will point to 0°.

13