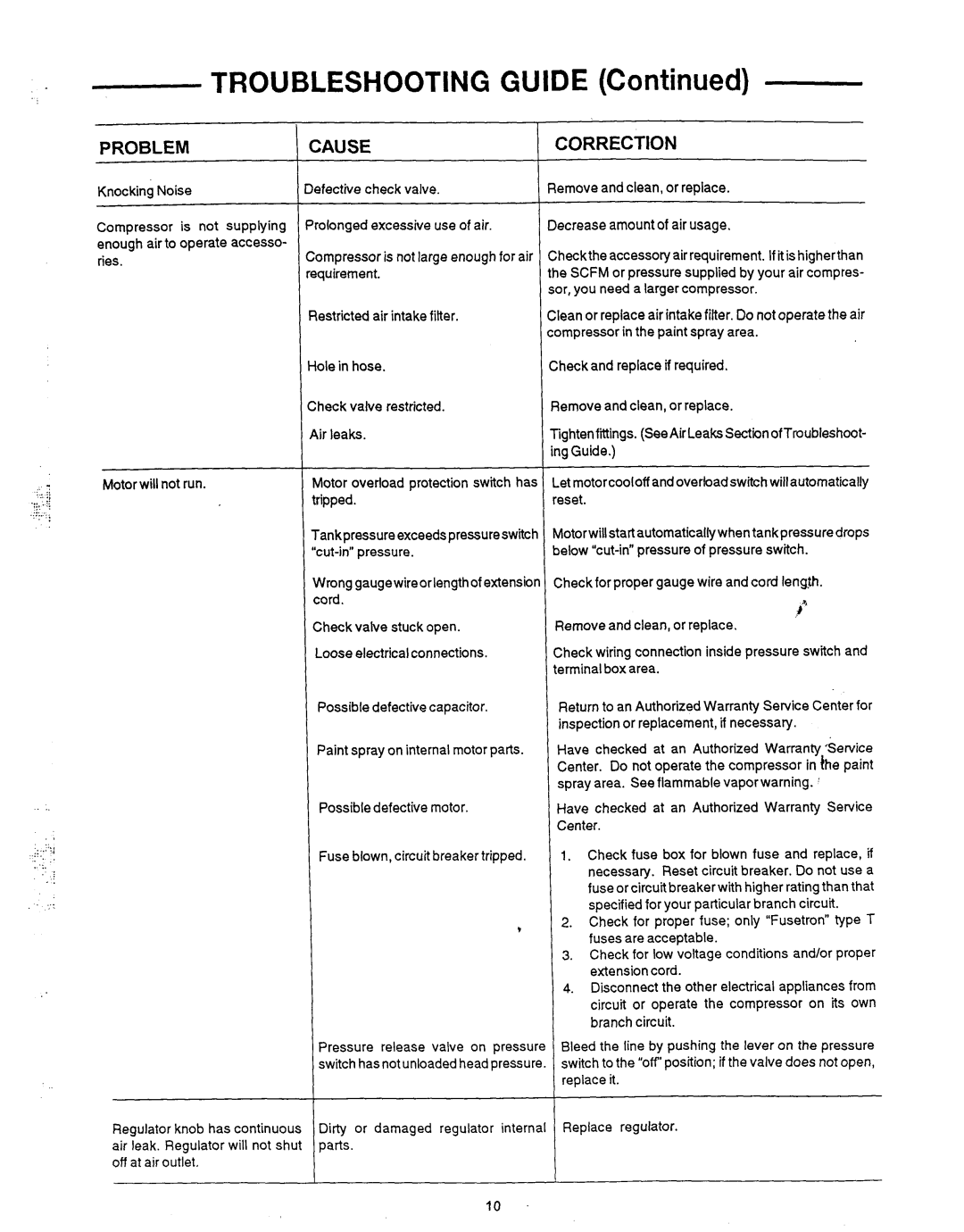

TROUBLESHOOTING GUIDE (Continued)

PROBLEMCAUSECORRECTION

Knocking Noise

Compressor is not supplying enough air to operate accesso- ries.

tefective check valve. | Remove and clean, or replace. |

|

| ~~ | |

Volonged excessive use of air. | Decrease amount of air usage. |

|

:ompressor is not large enough for air | Checkthe accessory airrequirement. If itis higherthan | |

equirement. | the SCFM or pressure supplied by your air compres- | |

| sor, you need a larger compressor. |

|

... ..

.. .I ,

X..' ::

..........,

__ ~

Motor will not run.

estricted air intakefilter.

ole in hose.

heck valve restricted.

,ir leaks.

Aotor overload protection switch ha: ripped.

'ank pressureexceedspressureswitc!

Nronggaugewireorlengthof extensioi :ord.

;heck valve stuck open.

Possible defective capacitor.

Clean or replace air intakefilter. Do not operate the air compressor in the paint spray area.

Check and replace if required.

Remove and clean, or replace.

Tightenfittings. (SeeAir LeaksSection ofTroubleshoot- ing Guide.)

Let motorcooloff andoverloadswitchwillautomatically eset.

hotorwill start automaticallywhen tank pressuredrops ielow

;heck for proper gauge wire and cord lenah.

a"

?emoveand clean, or replace.

;heck wiring connection inside pressure switch and erminalbox area.

Return to an AuthorizedWarranty Service Center for inspectionor replacement, if necessary.

Paint spray on internalmotor parts. | Have checked at an Authorized Warranty 'Service |

| Center. Do not operate the compressor in h e paint |

| spray area. See flammable vapor warning. ' |

Possibledefective motor. | Have checked at an Authorized Warranty Service |

| Center. |

....' ,,':,[

.1 .. ..

.. ..

Fuse blown, circuit breaker tripped.

| hessure release valve on pressur |

| switch has notunloaded headpressurc |

Regulator knob has continuou! | Dirty or damaged regulator intern; |

air leak. Regulator will not shu | parts. |

off at air outlet. |

|

1.Check fuse box for blown fuse and replace, if necessary. Reset circuit breaker. Do not use a fuse or circuitbreaker with higher ratingthan that specified for your particular branch circuit.

2.Check for proper fuse; only "Fusetron" type T fuses are acceptable.

3.Check for low voltage conditions and/or proper extension cord.

4.Disconnect the other electrical appliances from circuit or operate the compressor on its own branch circuit.

Bleed the line by pushing the lever on the pressure switch to the "off" position; if the valve does not open, replace it.

Replace regulator.

10