3038R, 3638R, 2438 specifications

Marley Engineered Products is renowned for its high-performance cooling solutions, and among its most notable offerings are the Marley 3038R, 3638R, and 2438 evaporative cooling towers. These models are designed with advanced technology and features that ensure efficient temperature regulation for various industrial applications, enhancing productivity while minimizing energy consumption.The Marley 3038R and 3638R models are distinguished by their robust construction and innovative design. They are made from high-quality materials that withstand harsh environmental conditions, ensuring longevity and reliability. Both cooling towers incorporate a modular design that eases installation and maintenance, promoting operational efficiency. The Marley 3038R is ideal for medium to large industrial settings, while the 3638R caters to larger operations needing more substantial cooling capacity.

One of the standout features of these models is the use of advanced film fill technology, which enhances heat exchange efficiency. This technology maximizes water-to-air contact, promoting effective cooling with reduced water consumption. Furthermore, the fan systems in these cooling towers are equipped with high-efficiency motors that operate quietly while delivering optimal airflow, thereby minimizing power expenditure.

The Marley 2438 model is particularly notable for its compact design, making it suitable for applications where space is a constraint. Despite its smaller size, it maintains high performance levels comparable to its larger counterparts, ensuring that users do not compromise on cooling efficiency.

All three models utilize durable and corrosion-resistant components that extend their service life and reduce maintenance needs. The units are designed for easy access to critical components, making routine inspections and repairs more straightforward and less time-consuming.

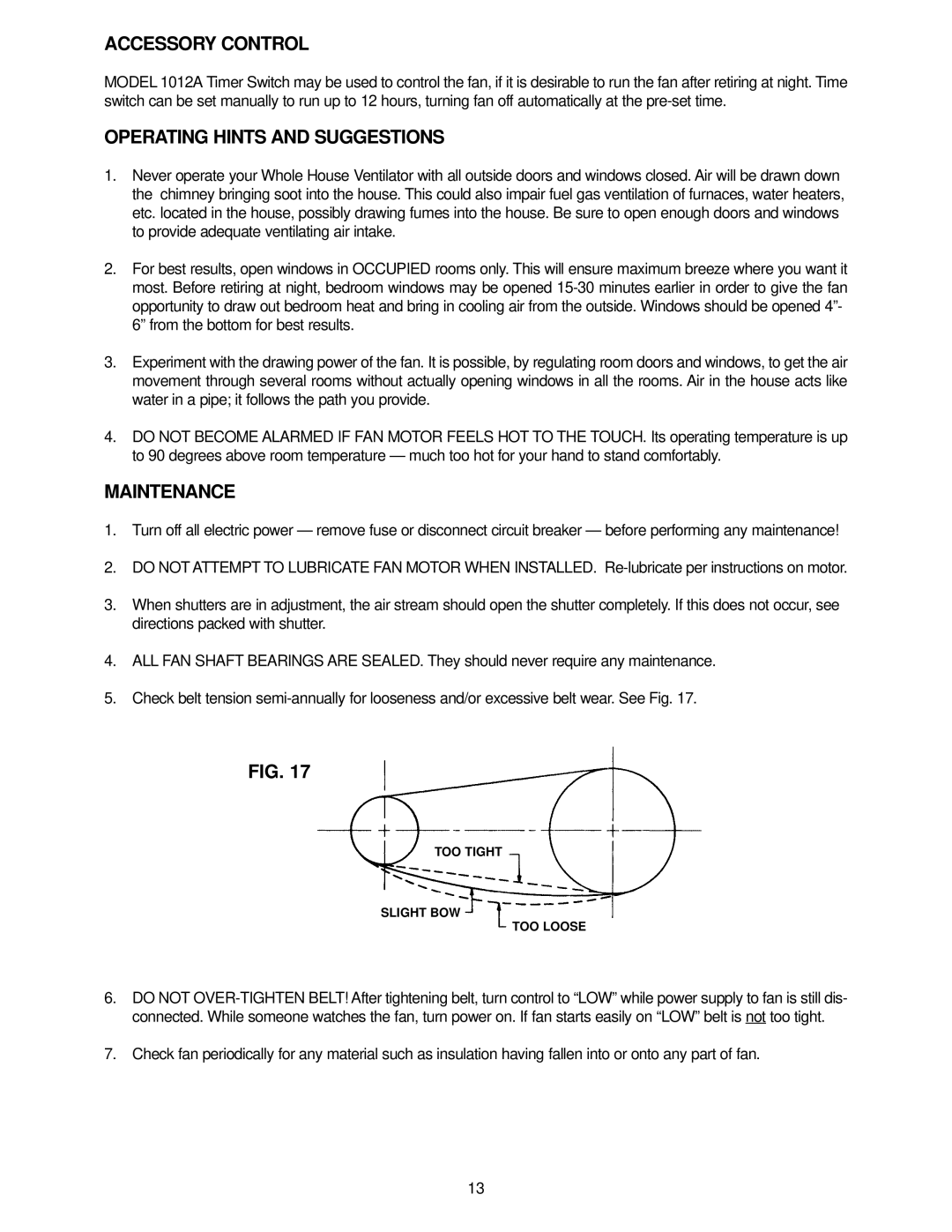

Additionally, Marley Engineered Products stands out for its commitment to sustainability. These cooling towers incorporate features that optimize water usage and reduce environmental impact. The cooling solutions provide a reliable and eco-friendly alternative for users looking to meet stringent sustainability goals without sacrificing performance.

In summary, the Marley 3038R, 3638R, and 2438 cooling towers epitomize efficiency, durability, and advanced technology in industrial cooling solutions. With their robust construction, innovative fill design, and energy-efficient components, they are well-suited for a diverse range of applications, making them a top choice for industries seeking reliable cooling performance. Whether for large-scale operations or space-limited environments, Marley Engineered Products delivers cutting-edge solutions to meet the demands of modern industry.