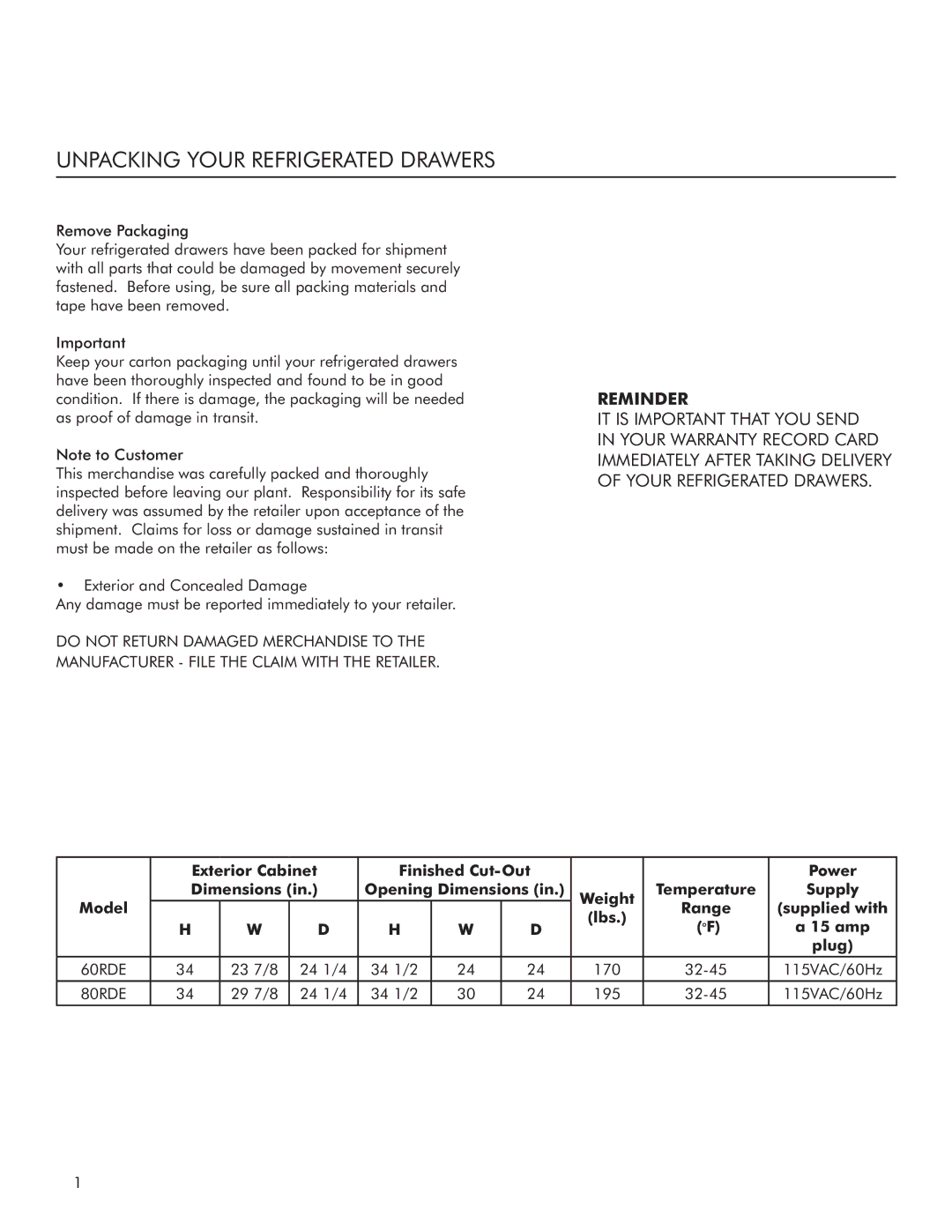

60RDE, 80RDE specifications

Marvel Industries has made a significant mark in the realm of advanced manufacturing technologies with its standout products, the 80RDE and 60RDE series. Designed for precision and efficiency, these machines have redefined the standards in the industry.The 80RDE model represents the pinnacle of automation in manufacturing. It boasts a robust yet compact design that allows it to function in various workspaces, making it an ideal choice for both small workshops and large factories. One of its most notable features is the high-speed spindle that can reach up to 20,000 RPM, enabling it to handle a diverse range of materials from soft plastics to hard metals. The spindle’s power combined with advanced cooling technology minimizes thermal expansion, yielding consistent precision even during prolonged operations.

Equipped with an intuitive user interface, the 80RDE allows operators to easily program and monitor tasks. Its compatibility with Industry 4.0 standards enables seamless integration into smart manufacturing ecosystems. This machine also features an automatic tool changer (ATC) that supports multiple tooling options, enhancing productivity and allowing for quick changeovers without manual intervention.

On the other hand, the 60RDE model is tailored for operations requiring a balance between performance and cost-effectiveness. It retains many of the innovative features of the 80RDE but simplifies certain aspects to cater to a broader range of users. Its maximum spindle speed is slightly lower at 15,000 RPM, yet it still offers impressive torque and efficiency. The 60RDE focuses on reliability, making it a favorite among businesses in high-demand manufacturing sectors that prioritize uptime and productivity.

Both models utilize cutting-edge servo motor technology that ensures precise positioning and repeatability. Moreover, they come equipped with advanced safety systems, including emergency stop buttons, light curtains, and overload protection, ensuring a safe working environment for operators.

In addition to their impressive technical specifications, both the 80RDE and 60RDE series are designed with sustainability in mind. They are energy-efficient solutions that help companies reduce their carbon footprint while maintaining high production levels.

In summary, the Marvel Industries 80RDE and 60RDE models illustrate the forward-thinking and technological prowess of the company. Their advanced features, versatility, and commitment to safety and sustainability make them essential tools for modern manufacturing, catering to the evolving needs of the industry. By investing in these machines, businesses can enhance their operational efficiency and future-proof their manufacturing capabilities.