PH-2100, PH-1100K specifications

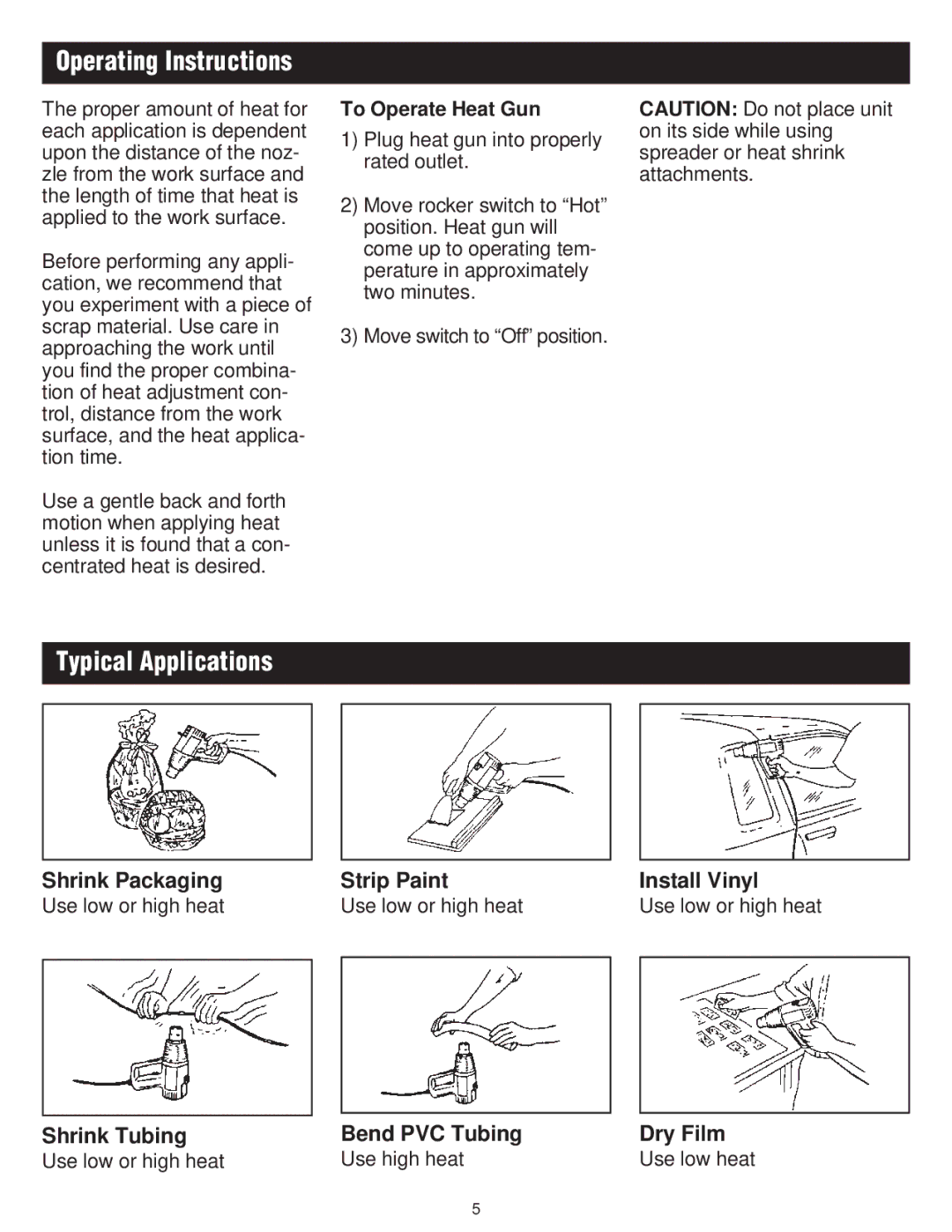

The Master Appliance PH-1100K and PH-2100 are industry-leading heat guns designed for professionals and DIY enthusiasts who demand reliability, performance, and versatility in their tools. Both models are engineered for a wide range of applications, including shrink wrapping, paint stripping, and surface drying, making them essential additions to any toolkit.The PH-1100K features a compact and lightweight design, making it easy to handle during prolonged use. It boasts a powerful 1100-watt motor that delivers rapid heating and a maximum temperature of 1,100 degrees Fahrenheit. This model includes two heat settings, allowing users to adjust the temperature according to specific tasks. The integrated overload protection ensures safety, automatically shutting off the tool in case of overheating, thereby extending its lifespan.

For users seeking enhanced performance, the PH-2100 takes it a step further with an increased wattage of 2100 watts. This model heats up quickly and reaches a maximum temperature of 1,200 degrees Fahrenheit. It also features an adjustable air velocity control, which permits users to switch between high and low airflow settings, providing better control over the application. The ergonomic design of both models ensures comfort during extended use, with an easy-to-grip handle that minimizes fatigue.

One notable characteristic of the Master Appliance heat guns is their versatility in accessories. Both the PH-1100K and the PH-2100 come with a variety of nozzles that cater to specific tasks. For instance, the flat nozzle is perfect for wide surfaces such as drying paint, while the round nozzle focuses heat on a specific point, ideal for shrink tubing or removing adhesive.

These heat guns are built with durability in mind, featuring a rugged exterior that can withstand tough working conditions. They are also designed with cooling vents that prevent the motor from becoming too hot, ensuring consistent performance over long periods.

Overall, the Master Appliance PH-1100K and PH-2100 are exceptional heat guns that deliver power, safety, and versatility for any heating need. Whether you are a professional tradesperson or a home DIYer, these models provide the efficiency and reliability required to tackle a wide range of tasks with ease and confidence.