9.Saw a 4',"_hole in floor and position dryer.

10.Secure the shortened pipe to the blower housing with a

screw at the top and seal all joints with tape or silicone bathtub caulk.

11. Install a 4" 90 degree elbow as shown.

FIG. #7 |

| REPLACESCREW |

| |

|

| ANDTA_7" 90 DEGREEELBOW | ||

|

|

| / | /I |

L_ | }lil_ |

| 4" DIAl7 |

|

| j | IL_I_ |

| |

| i1_ VENTPIPE |

|

| |

12.Seal rear opening of cabinet withthe coverplate provid- ed with your dryer. Located with literature. Attach cover plate to rear of the cabinet with #8 sheet metal screws or duct tape. (Not supplied)

13.Place cylinder belt around cylinder with grooved side

toward cylinder. FIG. #6.

14. Reinstall cylinder by pushing and turning until rollers are snapped in cylinder grooves and cylinder turns freely.

15. Position cylinder belt with grooved side around motor pulley. Pull idler pulley right until smooth side of belt can be routed around left side of idler pulley. FIG. #6.

16. Rotate cylinder

17, Replace dryer front and reconnect door switch wires,

Make sure the front seal is in the original position,

18. Complete exhaust system to outdoors,

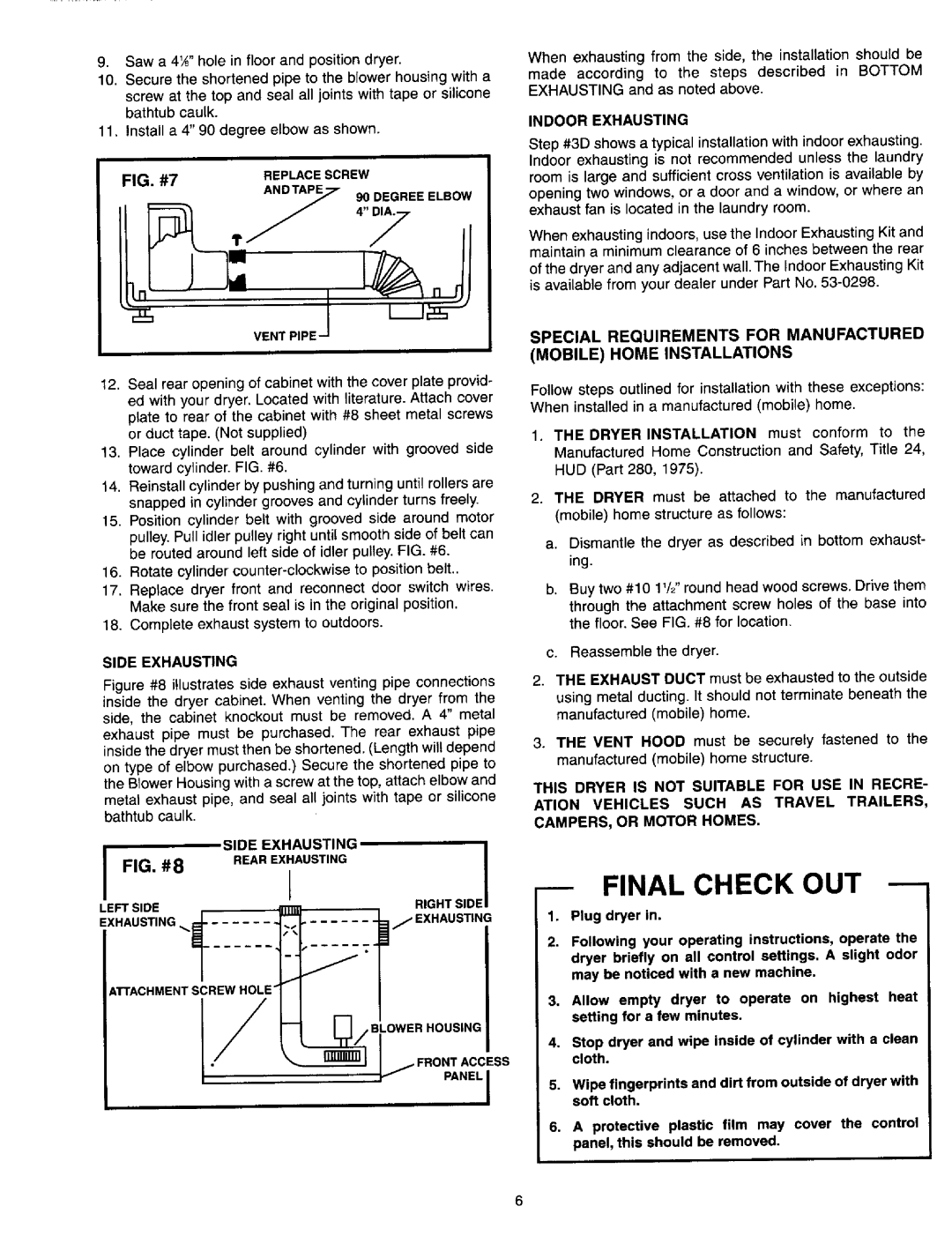

SIDE EXHAUSTING

Figure #8 illustratesside exhaust venting pipe connections inside the dryer cabinet. When venting the dryer from the side, the cabinet knockout must be removed. A 4" metal exhaust pipe must be purchased. The rear exhaust pipe inside the dryer must then be shortened. (Length will depend on type of elbow purchased.) Secure the shortened pipe to

the Blower Housing with a screw at the top, attach elbow and metal exhaust pipe, and seal all joints with tape or silicone

bathtub caulk.

SIDE EXHAUSTING

When exhausting from the side, the installation should be made according to the steps described in BOTTOM EXHAUSTING and as noted above.

INDOOR EXHAUSTING

Step #3D shows a typical installationwith indoor exhausting. Indoor exhausting is not recommended unless the laundry room is large and sufficient cross ventilation is available by opening two windows, or a door and a window, or where an

When exhausting indoors, use the Indoor Exhausting Kit and

of the dryer and any adjacent wall. The Indoor Exhausting Kit

exhaust fan is located in the laundry room.

iSavai from dea er under Part No.

maintalablein minimyourm clearance of 6 inches between the rear

SPECIAL REQUIREMENTS FOR MANUFACTURED

(MOBILE) HOME INSTALLATIONS

Follow steps outlined for installation with these exceptions: When installed in a manufactured (mobile) home.

1. THE DRYER INSTALLATION must conform to the

Manufactured Home Construction and Safety, Title 24, HUD (Part 280, 1975).

2. THE DRYER must be attached to the manufactured (mobile) home structure as follows:

a.Dismantle the dryer as described in bottom exhaust- ing.

b. Buy two #10 1'/2rou"nd head wood screws. Drive them

through the attachment screw holes of the base into the floor. See FIG. #8 for location.

c. Reassemble the dryer.

2.THE EXHAUST DUCT must be exhausted to the outside using metal ducting.It should not terminate beneath the manufactured(mobile)home.

3. THE VENT HOOD must be securely fastened to the manufactured (mobile) home structure.

THIS DRYER IS NOT SUITABLE FOR USE IN RECRE-

ATION VEHICLES SUCH AS TRAVEL TRAILERS, CAMPERS, OR MOTOR HOMES.

LEFT SIDEi111RIGHT SIDE

EXHAUSTING._- | _"_ | /EXHAUSTING | 1. | Plug dryer in. | |

| - |

| .;- | 2. | dryer briefly on all control settings, A slight odor |

| / |

| Following your operating instructions, operate the | ||

ATTACHMENT SCREW HOLE |

|

|

| may be noticed with a new machine. | |

|

|

|

|

| |

|

|

| /BLOWER HOUSING | 4, | setting for a few minutes. |

|

| [_ | Stop dryer and wipe inside of cylinder with a clean | ||

• | '_ | J1.1FRONT ACCESS | 3. | Allow empty dryer to operate on highest heat | |

|

| cloth. | |||

|

|

| PANELJ | 5. | Wipe fingerprints and dirt from outside of dryerwith |

|

|

| I |

| soft cloth. |

|

|

|

| 6. | A protective plastic film may cover the control |

|

|

|

|

| panel, this should be removed. |