ALMACENAJE

1. Almacena en la casa. Almacena la unidad en la temperatura superior a 32˚F(0˚C). Agua congelado en la bomba causará el daño permanete y la garantía del fabricante inválida.

•

1. Stockez à l'intérieur. Stockez l'appareil à une température supérieure à 32˚F (0˚C). De l'eau congelée dans la pompe provoquerait des dommages irrémédiables et annulerait la garantie du constructeur.

ADVERTENCIA

Cualquier otro servicio debe ser realizado por la personal de servicio autorizado.

PRECAUCION

Desconecta el cordón eléctrico antes de llenar el tanque químico. El tanque químico y linea de suministro deben ser E lavado con agua después del uso.

S • ACCESORIOS

P NOTA: Sólo use los accesorios y dispositivos adjuntos especialmente recomendados por el fabricante para el uso A con este producto. Los accesorios y el tubo rociador son conectados con el acomplamiento de bayoneta. El sello en Ñ el acomplamiento de bayoneta enchufado debe ser indemne.

O • EL USO DEL TANQUE QUIMICO

L NOTA: Sólo use las soluciones de limpieza recomendadas por el fabricante original.

1. Aprieta el aparato rociador de espuma en el contenedor llenado del agente de limpieza.

2. Fija el aparato rociador de espuma al tubo rociador.

3. Conecta el aparato. El agente de limpieza es agregado a razon de una parte por ciento.

STOCKAGE

•

• UTILISATION DU RESERVOIR DE PRODUIT CHIMIQUE

REMARQUE : Utilisez uniquement les accessoires et les pièces d'assemblage recommandés spécialement par le constructeur pour l'utilisation avec cette machine. Les accessoires et le tuyau de vaporisation sont connectés par des connexions à baïonnettes. Le joint sur la connexion a baionnettes doit être en bon état.

• ACCESSOIRES

F

R

A

N

C

A

I REMARQUE : Utilisez uniquement les authentiques solutions nettoyantes recommandées par le constructeur. S 1. Vissez l'appareil de pulvérisation de mousse sur le container rempli de la solution de nettoyage.

2. Fixez l'appareil de pulvérisation de mousse au tuyau de vaporisation.

3. Mettez en marche l'appareil. L'agent nettoyant est ajouté avec un coefficient de 1 : 100.

Déconnectez le cable d'alimentation avant de rémplir le réservoir de produit chimique. Le reservoir de produit chim- ique et les tuyaux d'alimentation doivent être rincés avec de l'eau après l'utilisation.

1. Store indoors. Store unit above 32˚F (0˚C). Frozen water in pump will cause permanent damage and void manufacturers warranty.

AVERTISSEMENT

Tout autre dépannage doit etre effectué par un personnel de depannage qualifié.

ATTENTION

STORAGE

•

WARNING

Any other servicing should be performed by an authorized sevice personnel.

CAUTION

Disconnect power cord before filling chemical tank. Chemical tank and supply lines must be flushed with water after

Euse.

N • ACCESSORIES

G | NOTE: Use only accessories and attachments specifically recommended by manufacturer for use with this product. |

L | Accessories and spray pipe are connected with bayonet coupling. The seal on the plug-in bayonet coupling must be |

I | undamaged. |

S• THE USE OF CHEMICAL TANK

HNOTE: Use only genuine manufacturer recommended cleaning solutions.

1.Screw detergent sprayer onto chemical tank filled with cleaning agent.

2.Attach detergent sprayer device to wand extension.

3.Switch on appliance. Cleaning agent is added in a ratio of 1 part per hundred.

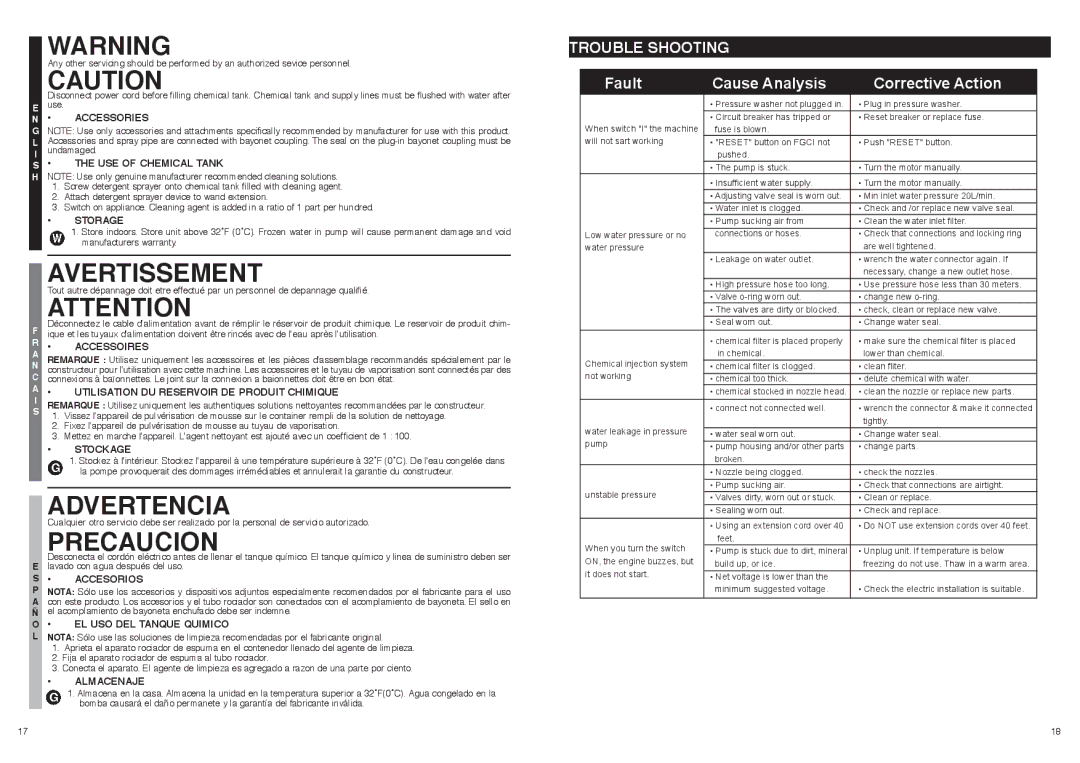

TROUBLE SHOOTING

| Fault | Cause Analysis | Corrective Action |

| | • Pressure washer not plugged in. | • Plug in pressure washer. |

| | • Circuit breaker has tripped or | • Reset breaker or replace fuse. |

| When switch "I" the machine | fuse is blown. | |

| will not sart working | • "RESET" button on FGCI not | • Push "RESET" button. |

| | pushed. | |

| | | |

| | • The pump is stuck. | • Turn the motor manually. |

| | • Insufficient water supply. | • Turn the motor manually. |

| | • Adjusting valve seal is worn out. | • Min inlet water pressure 20L/min. |

| | | |

| | • Water inlet is clogged. | • Check and /or replace new valve seal. |

| | • Pump sucking air from | • Clean the water inlet filter. |

| | | |

| Low water pressure or no | connections or hoses. | • Check that connections and locking ring |

| water pressure | | are well tightened. |

| | • Leakage on water outlet. | • wrench the water connector again. If |

| | | necessary, change a new outlet hose. |

| | | |

| | • High pressure hose too long. | • Use pressure hose less than 30 meters. |

| | | |

| | • Valve o-ring worn out. | • change new o-ring. |

| | • The valves are dirty or blocked. | • check, clean or replace new valve. |

| | | |

| | • Seal worn out. | • Change water seal. |

| | | |

| | • chemical filter is placed properly | • make sure the chemical filter is placed |

| | in chemical. | lower than chemical. |

| Chemical injection system | | |

| • chemical filter is clogged. | • clean fliter. |

| |

| not working | | |

| • chemical too thick. | • delute chemical with water. |

| |

| | • chemical stocked in nozzle head. | • clean the nozzle or replace new parts. |

| | | |

| | • connect not connected well. | • wrench the connector & make it connected |

| | | tightly. |

| water leakage in pressure | | |

| • water seal worn out. | • Change water seal. |

| |

| pump | | |

| • pump housing and/or other parts | • change parts. |

| |

| | broken. | |

| | • Nozzle being clogged. | • check the nozzles. |

| | | |

| | • Pump sucking air. | • Check that connections are airtight. |

| unstable pressure | • Valves dirty, worn out or stuck. | • Clean or replace. |

| |

| | | |

| | • Sealing worn out. | • Check and replace. |

| | | |

| | • Using an extension cord over 40 | • Do NOT use extension cords over 40 feet. |

| | feet. | |

| When you turn the switch | • Pump is stuck due to dirt, mineral | • Unplug unit. If temperature is below |

| |

| ON, the engine buzzes, but | build up, or ice. | freezing do not use. Thaw in a warm area. |

| |

| it does not start. | | |

| • Net voltage is lower than the | |

| | |

| | minimum suggested voltage. | • Check the electric installation is suitable. |

| | | |