G.

G.

ENGINE/SHAFT

ENGINE/SHAFT

ASSEMBLY

ASSEMBLY

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() A

A

DANGER. Do not run engine without shaft attached as clutch could fly off.

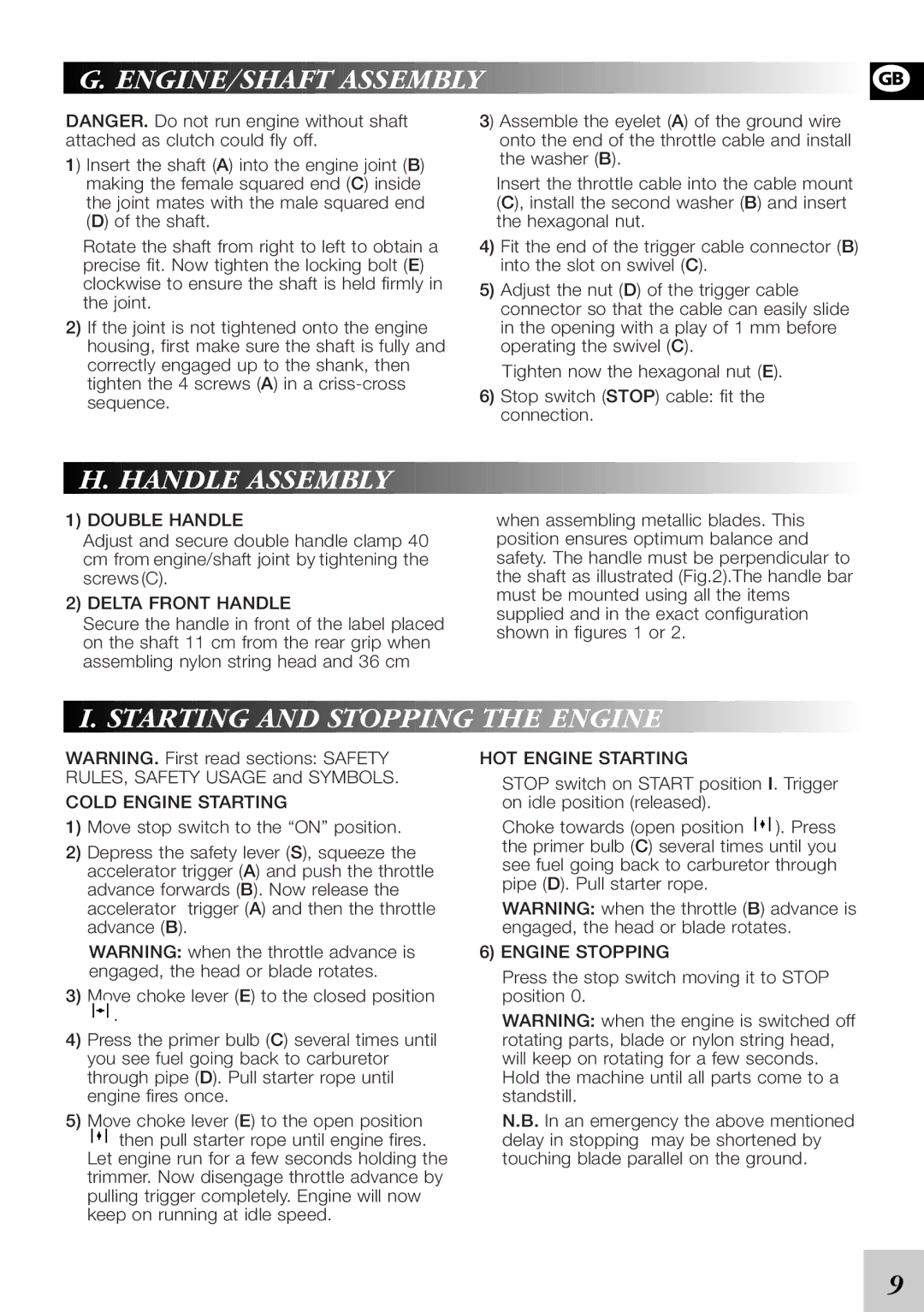

1) Insert the shaft (A) into the engine joint (B) making the female squared end (C) inside the joint mates with the male squared end (D) of the shaft.

Rotate the shaft from right to left to obtain a precise fit. Now tighten the locking bolt (E) clockwise to ensure the shaft is held firmly in the joint.

2)If the joint is not tightened onto the engine housing, first make sure the shaft is fully and correctly engaged up to the shank, then tighten the 4 screws (A) in a

3) Assemble the eyelet (A) of the ground wire onto the end of the throttle cable and install the washer (B).

Insert the throttle cable into the cable mount (C), install the second washer (B) and insert the hexagonal nut.

4)Fit the end of the trigger cable connector (B) into the slot on swivel (C).

5)Adjust the nut (D) of the trigger cable connector so that the cable can easily slide in the opening with a play of 1 mm before operating the swivel (C).

Tighten now the hexagonal nut (E).

6)Stop switch (STOP) cable: fit the connection.

H.

H.

HANDLE

HANDLE

ASSEMBLY

ASSEMBLY

1) DOUBLE HANDLE

Adjust and secure double handle clamp 40 cm from engine/shaft joint by tightening the screws(C).

2) DELTA FRONT HANDLE

Secure the handle in front of the label placed on the shaft 11 cm from the rear grip when assembling nylon string head and 36 cm

when assembling metallic blades. This position ensures optimum balance and safety. The handle must be perpendicular to the shaft as illustrated (Fig.2).The handle bar must be mounted using all the items supplied and in the exact configuration shown in figures 1 or 2.

I.

I.

STARTING

STARTING

AND

AND

STOPPING

STOPPING

THE

THE

ENGINE

ENGINE

WARNING. First read sections: SAFETY RULES, SAFETY USAGE and SYMBOLS.

COLD ENGINE STARTING

1)Move stop switch to the “ON” position.

2)Depress the safety lever (S), squeeze the accelerator trigger (A) and push the throttle advance forwards (B). Now release the accelerator trigger (A) and then the throttle advance (B).

WARNING: when the throttle advance is engaged, the head or blade rotates.

3)Move choke lever (E) to the closed position

![]()

![]()

![]() .

.

4)Press the primer bulb (C) several times until you see fuel going back to carburetor through pipe (D). Pull starter rope until engine fires once.

5)Move choke lever (E) to the open position

![]()

![]()

![]() then pull starter rope until engine fires. Let engine run for a few seconds holding the trimmer. Now disengage throttle advance by pulling trigger completely. Engine will now keep on running at idle speed.

then pull starter rope until engine fires. Let engine run for a few seconds holding the trimmer. Now disengage throttle advance by pulling trigger completely. Engine will now keep on running at idle speed.

HOT ENGINE STARTING

STOP switch on START position I. Trigger on idle position (released).

Choke towards (open position ![]()

![]()

![]() ). Press the primer bulb (C) several times until you see fuel going back to carburetor through pipe (D). Pull starter rope.

). Press the primer bulb (C) several times until you see fuel going back to carburetor through pipe (D). Pull starter rope.

WARNING: when the throttle (B) advance is engaged, the head or blade rotates.

6)ENGINE STOPPING

Press the stop switch moving it to STOP position 0.

WARNING: when the engine is switched off rotating parts, blade or nylon string head, will keep on rotating for a few seconds. Hold the machine until all parts come to a standstill.

N.B. In an emergency the above mentioned delay in stopping may be shortened by touching blade parallel on the ground.

9