pressors, pressure vessels and air tools.

AHazard generated by oil-satu- rated compressed air!

•Use oil saturated compressed air only for air tools requiring such sup- ply.

•Do not use an air hose used to sup- ply compressed air containing oil to supply air tools not designed for operation on compressed air con- taining oil.

•Do not fill tires with compressed air containing oil.

ARisk of burns from the sur- faces of parts carrying compressed air!

•Let tool cool off before servicing.

ARisk of personal injury and crushing by moving parts!

•Do not operate the electric tool with- out installed guards.

•Please note that the compressor will start automatically when the pres- sure falls off to minimum! – discon- nect from power supply prior to any servicing.

•Ensure that when turning ON (e.g. after servicing) no tools or loose parts are in the electric tool.

AHazard generated by insuffi- cient personal protection gear!

•Wear hearing protection.

•Wear safety glasses.

•Wear mask respirator when work generates dust or mist detrimental to health.

•Wear suitable work clothes. When working outdoors wearing of non- slip shoes is recommended.

AHazardtool defects!generated by electric

•Do not make changes to the com- pressor. Any modification to pres-

•Keep electric tool and accessories in good repair. Check and service

the compressor periodically. Observe the maintenance instruc- tions.

•Priot to any use check the electric tool for possible damage: before using the electric tool carefully check safety devices, protection devices or slightly damaged parts for proper function as specified.

•Check to see that all moving parts work properly and do not jam. All parts must be correctly installed and meet all conditions necessary for the proper operation of the electric tool.

•Damaged protection devices or parts must be repaired or replaced by a qualified specialist.

•Have damaged switches replaced by a service centre.

•Do not operate electric tool if the switch can not be turned ON or OFF.

•Keep handles free of oil and grease.

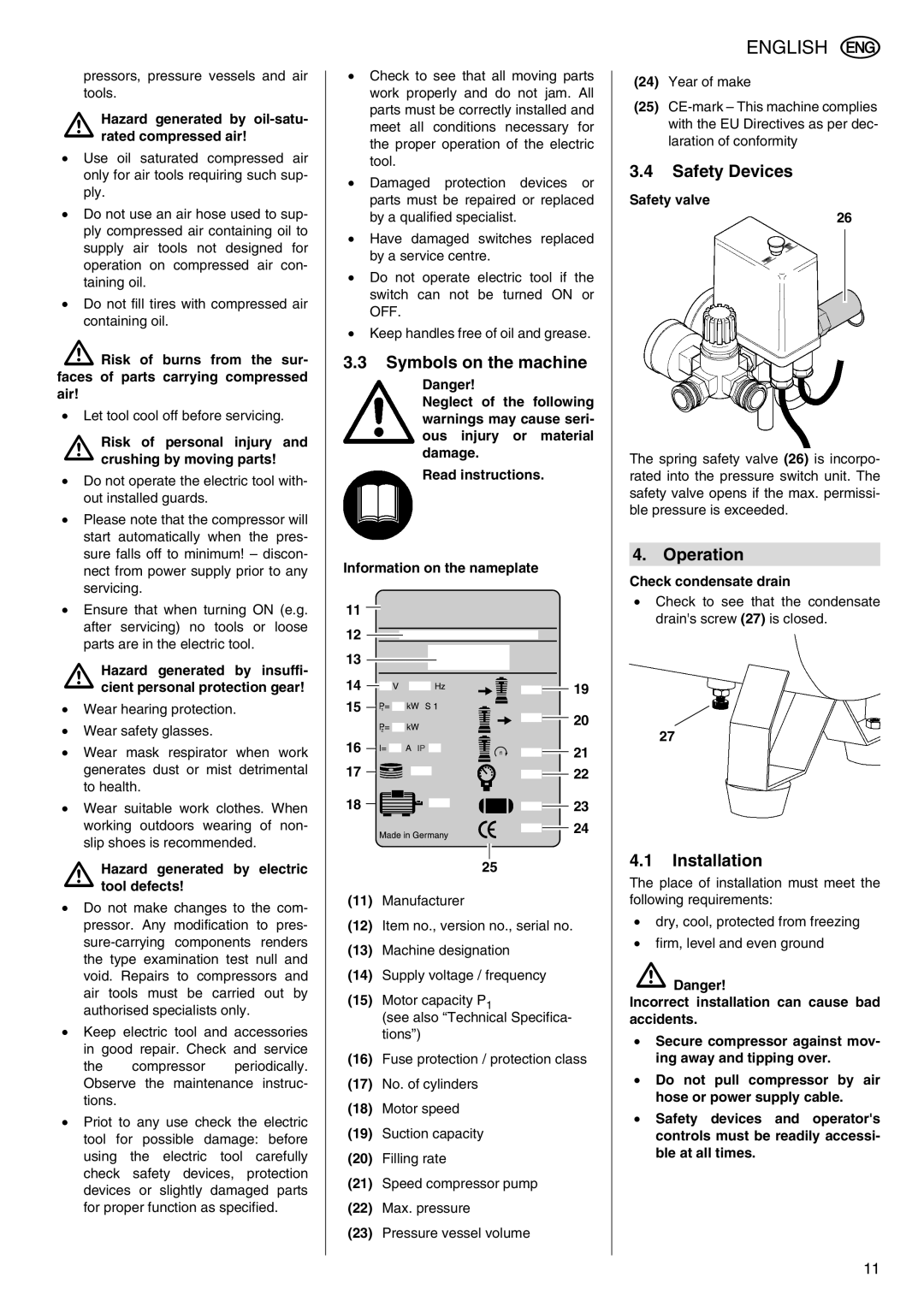

3.3Symbols on the machine

Danger!

Neglect of the following warnings may cause seri- ous injury or material damage.

Read instructions.

Information on the nameplate

11![]()

12![]()

13 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

14 |

|

|

|

|

|

|

|

| 19 | ||

|

|

| |||||||||

|

|

|

|

| |||||||

|

|

| |||||||||

|

|

|

|

|

| ||||||

15 |

|

|

|

|

|

|

|

|

|

| 20 |

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

| ||

16 |

|

|

|

|

| ||||||

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

| |

|

| 21 | |||||||||

|

|

| |||||||||

17 |

|

|

|

|

|

|

| 22 | |||

|

|

| |||||||||

|

|

|

| ||||||||

|

|

|

|

| |||||||

18 |

|

|

|

|

|

| 23 | ||||

|

|

| |||||||||

|

|

|

| ||||||||

|

|

|

|

|

| 24 | |||||

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 25 |

|

| ||||||

(11)Manufacturer

(12)Item no., version no., serial no.

(13)Machine designation

(14)Supply voltage / frequency

(15)Motor capacity P1

(see also “Technical Specifica- tions”)

(16)Fuse protection / protection class

(17)No. of cylinders

(18)Motor speed

(19)Suction capacity

(20)Filling rate

(21)Speed compressor pump

(22)Max. pressure

(23)Pressure vessel volume

ENGLISH

(24)Year of make

(25)

3.4Safety Devices

Safety valve

26

The spring safety valve (26) is incorpo- rated into the pressure switch unit. The safety valve opens if the max. permissi- ble pressure is exceeded.

4. Operation

Check condensate drain

•Check to see that the condensate drain's screw (27) is closed.

27

4.1Installation

The place of installation must meet the following requirements:

•dry, cool, protected from freezing

•firm, level and even ground

ADanger!

Incorrect installation can cause bad accidents.

•Secure compressor against mov- ing away and tipping over.

•Do not pull compressor by air hose or power supply cable.

•Safety devices and operator's controls must be readily accessi- ble at all times.

11