Your unit should be place on a

Also be sure to allow enough room at the rear of the Woodchuck for installation of the circulating blower and filter box.

If using your unit as an

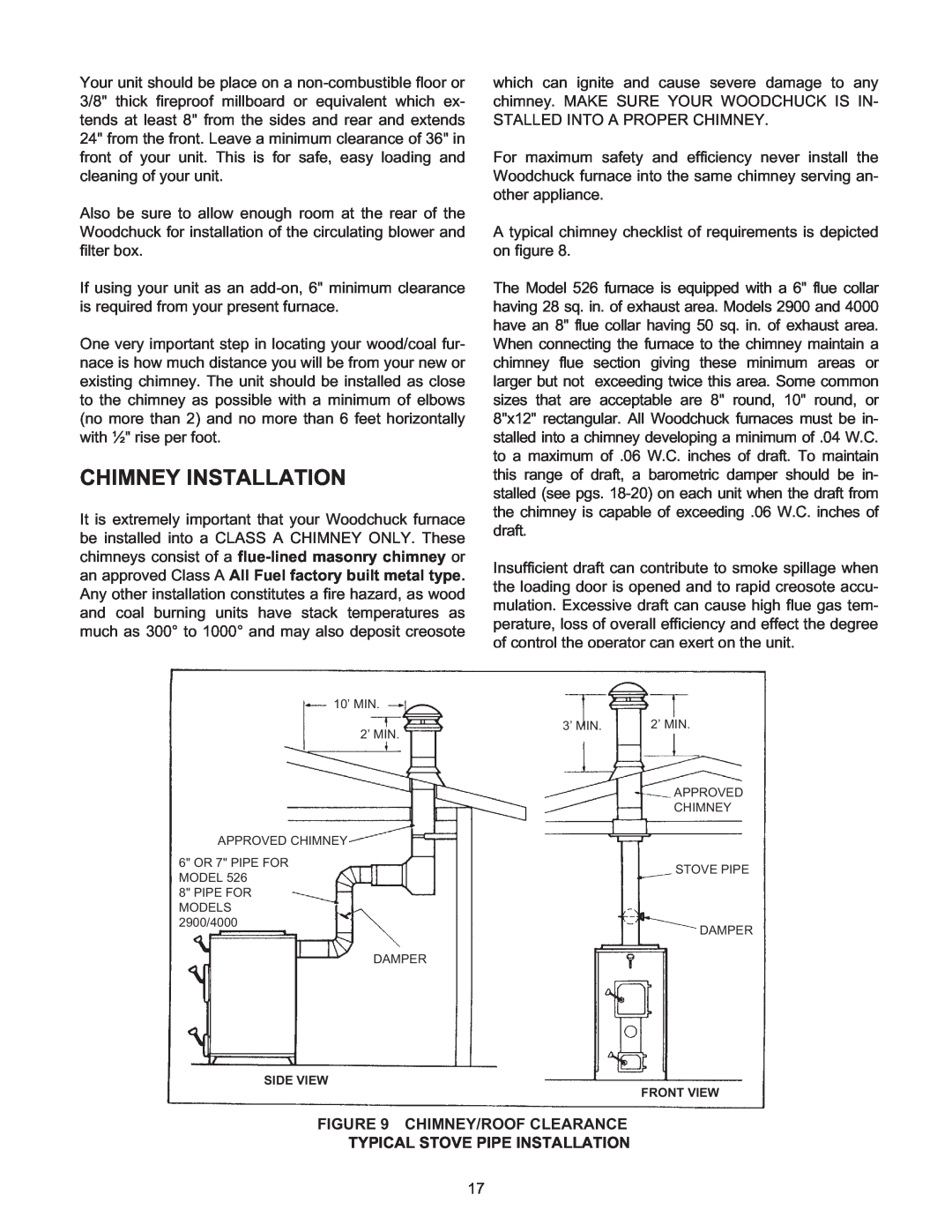

One very important step in locating your wood/coal fur- nace is how much distance you will be from your new or existing chimney. The unit should be installed as close to the chimney as possible with a minimum of elbows (no more than 2) and no more than 6 feet horizontally with ½" rise per foot.

CHIMNEY INSTALLATION

It is extremely important that your Woodchuck furnace be installed into a CLASS A CHIMNEY ONLY. These chimneys consist of a

which can ignite and cause severe damage to any chimney. MAKE SURE YOUR WOODCHUCK IS IN-

STALLED INTO A PROPER CHIMNEY.

For maximum safety and efficiency never install the Woodchuck furnace into the same chimney serving an- other appliance.

A typical chimney checklist of requirements is depicted on figure 8.

The Model 526 furnace is equipped with a 6" flue collar having 28 sq. in. of exhaust area. Models 2900 and 4000 have an 8" flue collar having 50 sq. in. of exhaust area. When connecting the furnace to the chimney maintain a chimney flue section giving these minimum areas or larger but not exceeding twice this area. Some common sizes that are acceptable are 8" round, 10" round, or 8"x12" rectangular. All Woodchuck furnaces must be in- stalled into a chimney developing a minimum of .04 W.C. to a maximum of .06 W.C. inches of draft. To maintain this range of draft, a barometric damper should be in- stalled (see pgs.

Insufficient draft can contribute to smoke spillage when the loading door is opened and to rapid creosote accu- mulation. Excessive draft can cause high flue gas tem- perature, loss of overall efficiency and effect the degree of control the operator can exert on the unit.

10’ MIN. |

|

3’ MIN. | 2’ MIN. |

2’ MIN. |

|

APPROVED

CHIMNEY

APPROVED CHIMNEY

6" OR 7" PIPE FOR MODEL 526

8" PIPE FOR MODELS 2900/4000

STOVE PIPE

DAMPER

DAMPER

SIDE VIEW

FRONT VIEW

FIGURE 9 CHIMNEY/ROOF CLEARANCE

TYPICAL STOVE PIPE INSTALLATION

17