SECTION 1 - DESCRIPTION

ENGLISH

I.OVEN USES

PS500 Series Ovens can be used to bake and/or cook a wide variety of food products, such as pizza,

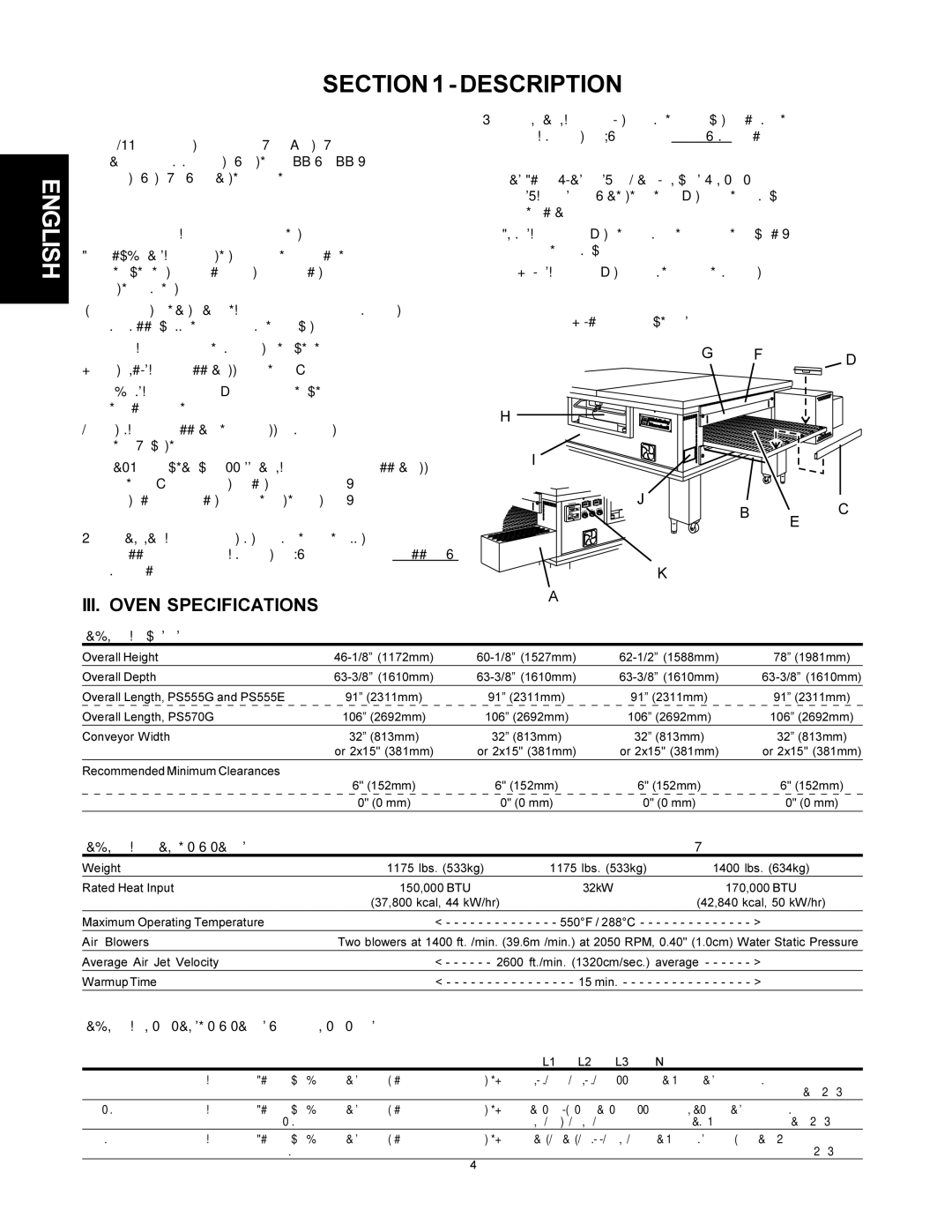

II. OVEN COMPONENTS - see Figure 1-1.

A.Conveyor Drive Motor: Moves the conveyor.

B.Crumb Pans: Catch crumbs and other material that drop through the conveyor belt. One crumb pan is located at each end of the conveyor.

C,D. Conveyor End Stop and Rear Stop: Prevent food products from falling off the end or rear of the moving conveyor.

E.Conveyor: Moves the food product through the oven.

F.End Plugs: Allow access to the oven's interior.

G.Eyebrows: Can be adjusted to various heights to prevent heat loss into the environment.

H.Window: Allows the user to access food products inside the baking chamber.

I.Machinery Compartment Access Panel: Allows access to the oven's interior and control components. No user- servicable parts are located in the machinery compart- ment.

J.Serial Plate: Provides specifications for the oven that affect installation and operation. Refer to Section 2, Installation, for details.

III. OVEN SPECIFICATIONS

K.Control Panel: Location of the operating controls for the oven. Refer to Section 3, Operation, for details.

Not Shown:

L.Gas Burner (gas ovens) or Heating Elements (electric ovens): Heat air, which is then projected to the air fingers by the blowers.

M.Blowers: Project hot air from the burner or heating ele- ments to the air fingers.

N.Air Fingers: Project streams of hot air onto the food product.

Figure 1-1 - Oven Components

G FD

H

I

J

BC

E

K

A

Table |

|

|

|

|

|

| Single Oven |

|

|

|

|

|

|

|

| Double Oven |

|

|

|

|

|

|

|

| Triple Oven |

|

|

|

|

|

|

|

| Quad Oven | ||||||||||||||||||||||||||||

Overall Height |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 78” (1981mm) | ||||||||||||||||||||||||||||||||||||

Overall Depth |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||||||||||||||||||||||||||||

Overall Length, PS555G and PS555E |

|

|

|

|

|

|

|

|

| 91” (2311mm) |

|

|

|

|

|

|

|

| 91” (2311mm) |

|

|

|

|

|

|

|

| 91” (2311mm) |

|

|

|

|

|

|

|

| 91” (2311mm) | |||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Overall Length, PS570G |

|

|

|

|

|

|

|

| 106” (2692mm) |

|

|

|

|

|

|

|

| 106” (2692mm) |

|

|

|

|

|

|

| 106” (2692mm) |

|

|

|

|

|

|

| 106” (2692mm) | ||||||||||||||||||||||||||||

Conveyor Width |

|

|

|

|

|

| 32” (813mm) |

|

|

|

|

|

|

|

|

| 32” (813mm) |

|

|

|

|

|

|

|

|

| 32” (813mm) |

|

|

|

|

|

|

|

| 32” (813mm) | ||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| or 2x15" (381mm) |

|

|

|

|

|

|

| or 2x15" (381mm) |

|

|

|

|

|

| or 2x15" (381mm) |

|

|

|

|

|

| or 2x15" (381mm) | |||||||||||||||||||||||||

Recommended Minimum Clearances |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||

|

|

|

| Rear of Oven (inc. rear shrouds) to Wall |

|

|

|

|

|

|

| 6" (152mm) |

|

|

|

|

|

|

|

|

| 6" (152mm) |

|

|

|

|

|

|

|

|

| 6" (152mm) |

|

|

|

|

|

|

|

|

| 6" (152mm) | ||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

| Conveyor Extension to Wall (both ends) |

|

|

|

|

|

|

|

| 0" (0 mm) |

|

|

|

|

|

|

|

|

| 0" (0 mm) |

|

|

|

|

|

|

|

|

| 0" (0 mm) |

|

|

|

|

|

|

|

|

| 0" (0 mm) | |||||||||||||||||||

Table | PS555G |

|

| PS555E |

|

| PS570G |

| ||

Weight | 1175 lbs. (533kg) | 1175 lbs. (533kg) |

| 1400 lbs. (634kg) | ||||||

Rated Heat Input | 150,000 BTU |

| 32kW |

| 170,000 BTU | |||||

| (37,800 kcal, 44 kW/hr) |

|

|

|

| (42,840 kcal, 50 kW/hr) | ||||

Maximum Operating Temperature | < - - - - - - - - - - - - - - 550°F / 288°C - - - - - - - - - - - - - - > |

| ||||||||

Air Blowers | Two blowers at 1400 ft.3/min. (39.6m3/min.) at 2050 RPM, 0.40" (1.0cm) Water Static Pressure | |||||||||

Average Air Jet Velocity | < - - - - - - 2600 ft./min. (1320cm/sec.) average - - - - - - > |

| ||||||||

Warmup Time |

| < - - - - - - - - - - - - - - - - 15 min. - - - - - - - - - - - - - - - - > |

| |||||||

Table |

|

|

|

|

|

|

| |||

Main Blower |

|

|

| Current Draw (per line) | kW |

|

| |||

Voltage | Control Circuit Voltage | Phase | Freq | L1 | L2 | L3 | N | Rating | Poles | Wires |

208V | 120V conveyor speed controller (w/transformer); | 3 Ph | 50/60Hz | 97.4A | 88.8A | 97.4A | 32kW | 3 Pole | 4 Wire | |

| all other control circuits 208V |

|

|

|

|

|

|

|

| (3 hot, 1 gd) |

120V conveyor speed controller (w/transformer); | 3 Ph | 50/60Hz | 83.0- | 75.0- | 83.0- | 29.3- | 3 Pole | 4 Wire | ||

| all other control circuits |

|

| 90.0A | 86.0A | 90.0A |

| 34.8kW |

| (3 hot, 1 gd) |

480V | 120V conveyor speed controller (w/transformer); | 3 Ph | 50/60Hz | 38.5A | 38.5A | 47.7A | 9.2A | 32kW | 4 Pole | 5 Wire (3 hot, |

| all other control circuits 240V |

|

|

|

|

|

|

|

| 1 neut, 1 gnd) |

4