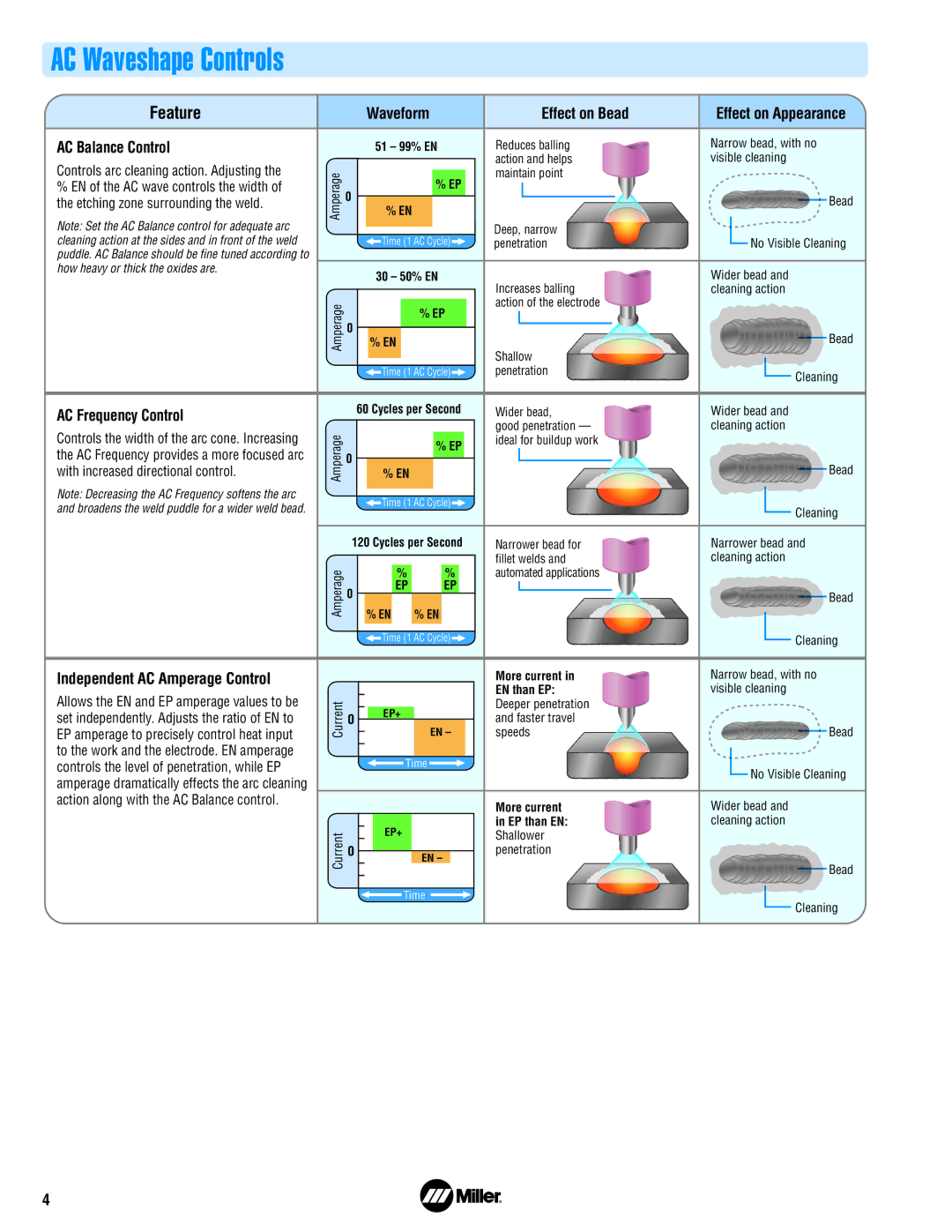

AC Waveshape Controls

Feature |

|

| Waveform | Effect on Bead | Effect on Appearance | |

AC Balance Control |

|

| 51 – 99% EN | Reduces balling | Narrow bead, with no | |

Controls arc cleaning action. Adjusting the |

|

|

|

| action and helps | visible cleaning |

Amperage |

|

| % EP | maintain point |

| |

% EN of the AC wave controls the width of | 0 |

|

| Bead | ||

|

|

| ||||

the etching zone surrounding the weld. |

| % EN |

|

| ||

|

|

|

| |||

|

|

|

|

|

| |

Note: Set the AC Balance control for adequate arc |

|

|

|

| Deep, narrow |

|

cleaning action at the sides and in front of the weld |

|

| Time (1 AC Cycle) | penetration | No Visible Cleaning | |

puddle. AC Balance should be fine tuned according to |

|

|

|

|

|

|

how heavy or thick the oxides are. |

|

| 30 – 50% EN |

| Wider bead and | |

|

|

| Increases balling | |||

|

|

|

|

| cleaning action | |

| Amperage |

|

| % EP | action of the electrode |

|

| 0 |

|

|

| ||

|

|

|

|

| ||

|

| % EN |

|

| Bead | |

|

|

|

| Shallow | ||

|

|

|

|

|

| |

|

|

| Time (1 AC Cycle) | penetration | Cleaning | |

|

|

|

|

|

| |

AC Frequency Control |

|

| 60 Cycles per Second | Wider bead, | Wider bead and | |

|

|

|

| |||

Controls the width of the arc cone. Increasing | Amperage |

|

|

| good penetration — | cleaning action |

| % EN | % EP | ideal for buildup work | Bead | ||

with increased directional control. |

|

| ||||

the AC Frequency provides a more focused arc |

| 0 |

|

|

|

|

Note: Decreasing the AC Frequency softens the arc |

|

| Time (1 AC Cycle) |

|

| |

and broadens the weld puddle for a wider weld bead. |

|

|

| Cleaning | ||

|

|

|

|

| ||

|

|

|

|

|

| |

|

| 120 Cycles per Second | Narrower bead for | Narrower bead and | ||

|

|

|

|

| fillet welds and | cleaning action |

| Amperage |

| % | % | automated applications |

|

| 0 | EP | EP |

| Bead | |

|

|

| ||||

|

|

|

|

| ||

|

|

|

|

|

| |

|

|

| % EN | % EN |

|

|

|

|

| Time (1 AC Cycle) |

| Cleaning | |

Independent AC Amperage Control |

|

|

|

| More current in | Narrow bead, with no |

Allows the EN and EP amperage values to be |

|

|

|

| EN than EP: | visible cleaning |

Current |

| EP+ | EN – | Deeper penetration | Bead | |

EP amperage to precisely control heat input |

| speeds | ||||

set independently. Adjusts the ratio of EN to |

| 0 |

|

| and faster travel |

|

to the work and the electrode. EN amperage |

|

| Time |

|

| |

controls the level of penetration, while EP |

|

|

| No Visible Cleaning | ||

amperage dramatically effects the arc cleaning |

|

|

|

|

| |

|

|

|

|

|

| |

action along with the AC Balance control. |

|

|

|

| More current | Wider bead and |

|

|

|

|

| ||

|

|

| EP+ |

| in EP than EN: | cleaning action |

| Current |

|

| Shallower |

| |

| 0 |

| EN – | penetration |

| |

|

|

|

| |||

|

|

|

|

| Bead | |

|

|

|

|

|

| |

|

|

| Time |

| Cleaning | |

|

|

|

|

|

| |

4