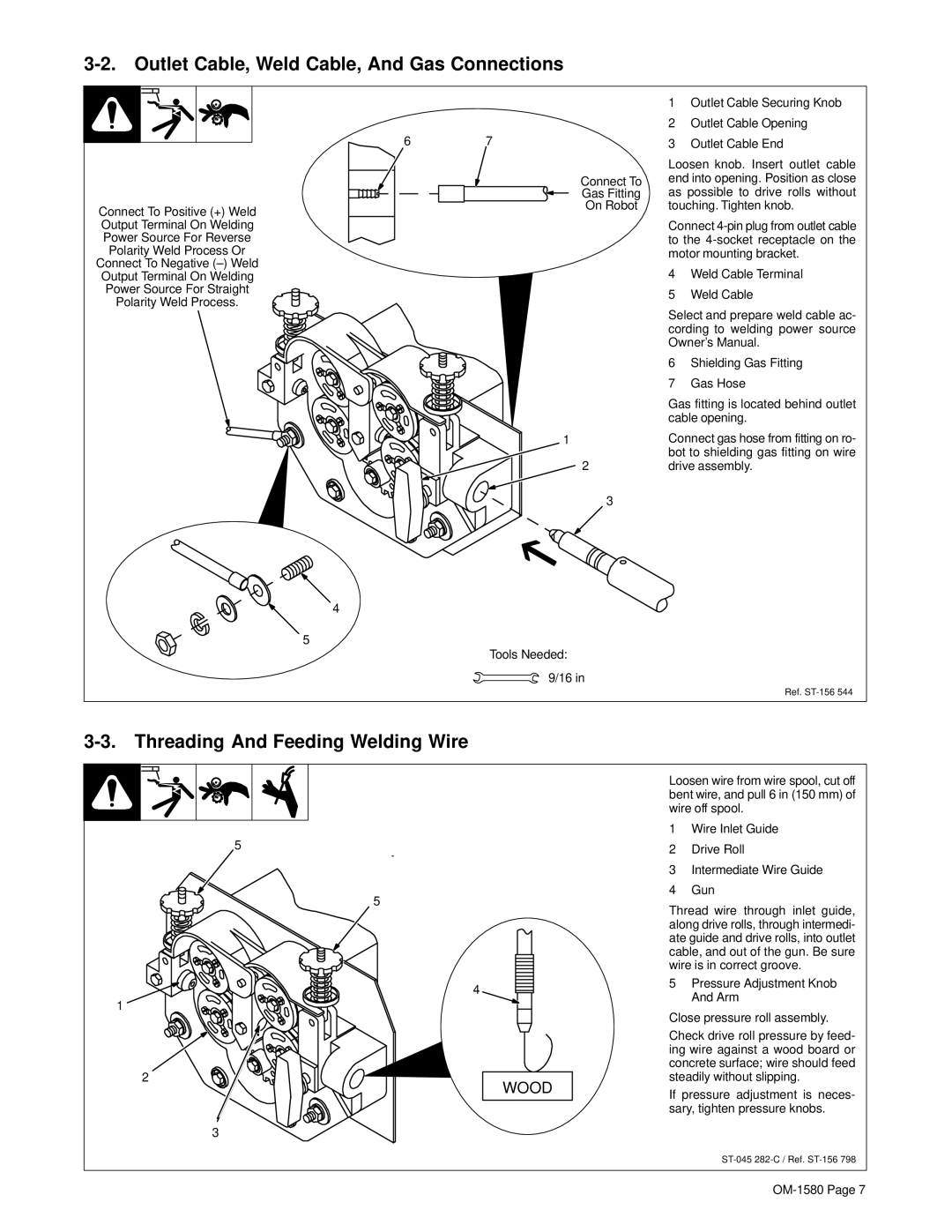

3-2. Outlet Cable, Weld Cable, And Gas Connections

Connect To Positive (+) Weld

Output Terminal On Welding

Power Source For Reverse

Polarity Weld Process Or

Connect To Negative

Output Terminal On Welding

Power Source For Straight

Polarity Weld Process.

67

Connect To

Gas Fitting

On Robot

1

2

3

4

5

Tools Needed:

9/16 in

1Outlet Cable Securing Knob

2Outlet Cable Opening

3Outlet Cable End

Loosen knob. Insert outlet cable end into opening. Position as close as possible to drive rolls without touching. Tighten knob.

Connect

4Weld Cable Terminal

5Weld Cable

Select and prepare weld cable ac- cording to welding power source Owner’s Manual.

6Shielding Gas Fitting

7Gas Hose

Gas fitting is located behind outlet cable opening.

Connect gas hose from fitting on ro- bot to shielding gas fitting on wire drive assembly.

Ref.

3-3. Threading And Feeding Welding Wire

5

5

4

1

2

WOOD

3

Loosen wire from wire spool, cut off bent wire, and pull 6 in (150 mm) of wire off spool.

1Wire Inlet Guide

2Drive Roll

3Intermediate Wire Guide

4Gun

Thread wire through inlet guide, along drive rolls, through intermedi- ate guide and drive rolls, into outlet cable, and out of the gun. Be sure wire is in correct groove.

5Pressure Adjustment Knob And Arm

Close pressure roll assembly.

Check drive roll pressure by feed- ing wire against a wood board or concrete surface; wire should feed steadily without slipping.

If pressure adjustment is neces- sary, tighten pressure knobs.