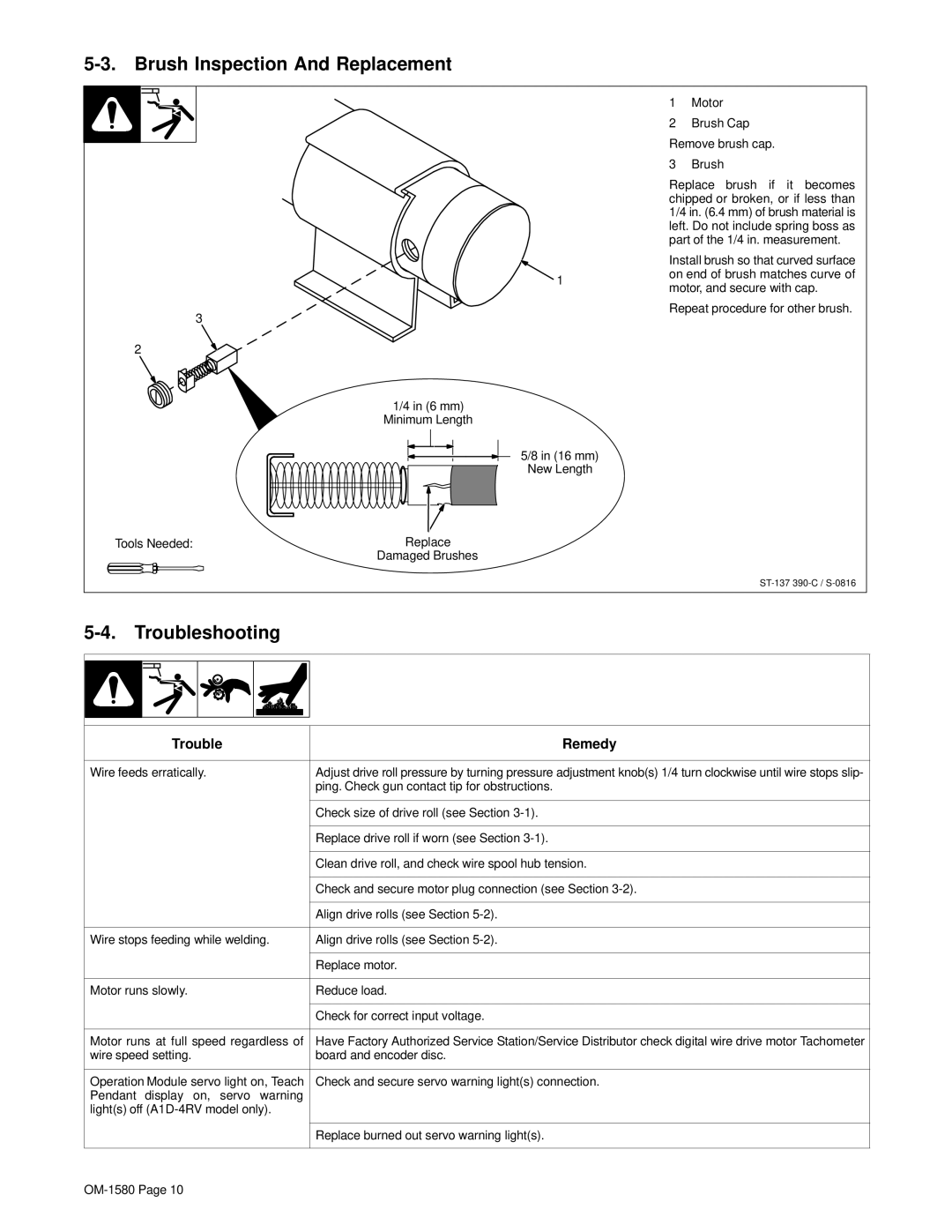

5-3. Brush Inspection And Replacement

| 1 |

| 3 |

2 |

|

| 1/4 in (6 mm) |

| Minimum Length |

| 5/8 in (16 mm) |

| New Length |

Tools Needed: | Replace |

| Damaged Brushes |

1Motor

2Brush Cap

Remove brush cap.

3 Brush

Replace brush if it becomes chipped or broken, or if less than 1/4 in. (6.4 mm) of brush material is left. Do not include spring boss as part of the 1/4 in. measurement.

Install brush so that curved surface on end of brush matches curve of motor, and secure with cap.

Repeat procedure for other brush.

5-4. Troubleshooting

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Trouble | Remedy | ||

|

| |||

Wire feeds erratically. | Adjust drive roll pressure by turning pressure adjustment knob(s) 1/4 turn clockwise until wire stops slip- | |||

|

|

|

| ping. Check gun contact tip for obstructions. |

|

|

|

|

|

|

|

|

| Check size of drive roll (see Section |

|

|

|

|

|

|

|

|

| Replace drive roll if worn (see Section |

|

|

|

|

|

|

|

|

| Clean drive roll, and check wire spool hub tension. |

|

|

|

|

|

|

|

|

| Check and secure motor plug connection (see Section |

|

|

|

|

|

|

|

|

| Align drive rolls (see Section |

|

| |||

Wire stops feeding while welding. | Align drive rolls (see Section | |||

|

|

|

|

|

|

|

|

| Replace motor. |

|

| |||

Motor runs slowly. | Reduce load. | |||

|

|

|

|

|

|

|

|

| Check for correct input voltage. |

|

| |||

Motor runs at full speed regardless of | Have Factory Authorized Service Station/Service Distributor check digital wire drive motor Tachometer | |||

wire speed setting. | board and encoder disc. | |||

|

| |||

Operation Module servo light on, Teach | Check and secure servo warning light(s) connection. | |||

Pendant display on, servo warning |

| |||

light(s) off |

| |||

|

|

|

|

|

|

|

|

| Replace burned out servo warning light(s). |

|

|

|

|

|