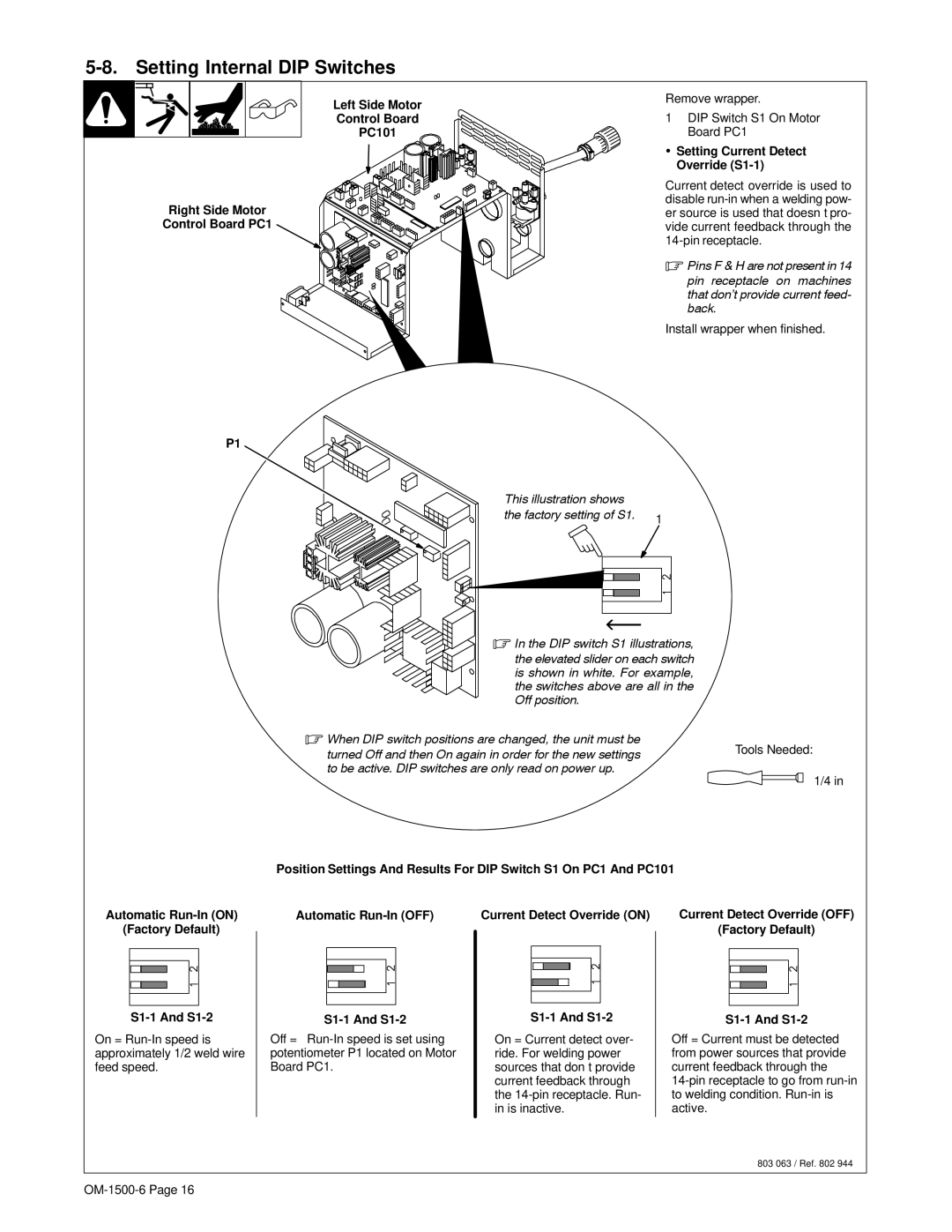

5-8. Setting Internal DIP Switches

Right Side Motor

Control Board PC1

P1

Left Side Motor

Control Board

PC101

Remove wrapper.

1DIP Switch S1 On Motor Board PC1

wSetting Current Detect Override (S1-1)

Current detect override is used to disable

.Pins F & H are not present in 14 pin receptacle on machines that don’t provide current feed- back.

Install wrapper when finished.

This illustration shows |

|

the factory setting of S1. | 1 |

|

. In the DIP switch S1 illustrations, the elevated slider on each switch is shown in white. For example, the switches above are all in the Off position.

.When DIP switch positions are changed, the unit must be

turned Off and then On again in order for the new settings to be active. DIP switches are only read on power up.

Tools Needed:

1/4 in

Position Settings And Results For DIP Switch S1 On PC1 And PC101

Automatic

(Factory Default)

On =

Automatic Run-In (OFF)

S1-1 And S1-2

Off =

Current Detect Override (ON)

S1-1 And S1-2

On = Current detect over- ride. For welding power sources that don’t provide current feedback through the

Current Detect Override (OFF)

(Factory Default)

S1-1 And S1-2

Off = Current must be detected from power sources that provide current feedback through the

803 063 / Ref. 802 944