Specifications (Subject to change without notice.)

|

|

|

| Weld Output Rated |

| Sound Levels |

|

|

Welding |

| Amp/Volt | at 100% Duty Cycle |

| at Rated Output, |

| Net | |

Mode | Process | Ranges | (at 104˚ F/40˚ C) | Generator Power | 7 m (23 ft) | Dimensions | Weight | |

CV/DC | MIG/FCAW | 19 | – 28 V | 200 A at 20 V | 75.5 dB | H: 33 in | 540 lb | |

CC/DC | Stick/TIG | 50 | – 210 A | 210 A at 25 V | Peak: 10,500 watts | (100.5 Lwa) | (838 mm) | (245 kg) |

Continuous: 9500 watts 120/240 VAC, 84/42 A |

| W: 20 in |

| |||||

CC/AC | Stick/TIG | 50 | – 225 A | 225 A at 25 V |

|

| ||

| (508 mm) |

| ||||||

|

|

|

|

|

| D: |

| |

|

|

|

|

| Peak: 11,000 watts |

|

| |

|

|

|

|

|

| (1156 mm) |

| |

|

|

|

|

| Continuous: 10,000 watts 480 V, 13 A |

|

| |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

Engine Specifications (Subject to change without notice.)

Engine Brand | Horsepower (HP) | Type | Weld Speed | Idle Speed | Fuel Capacity | Oil Capacity | |

Kohler: | 23 | HP (gas), | 3600 RPM | 2300 RPM | 12 gal (45 L) | 1.75 qt (1.7 L), 2 qt (1.9 L) with filter | |

3 year mfg. | 25 | HP (LP) at 3600 RPM |

|

|

|

| |

warranty |

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

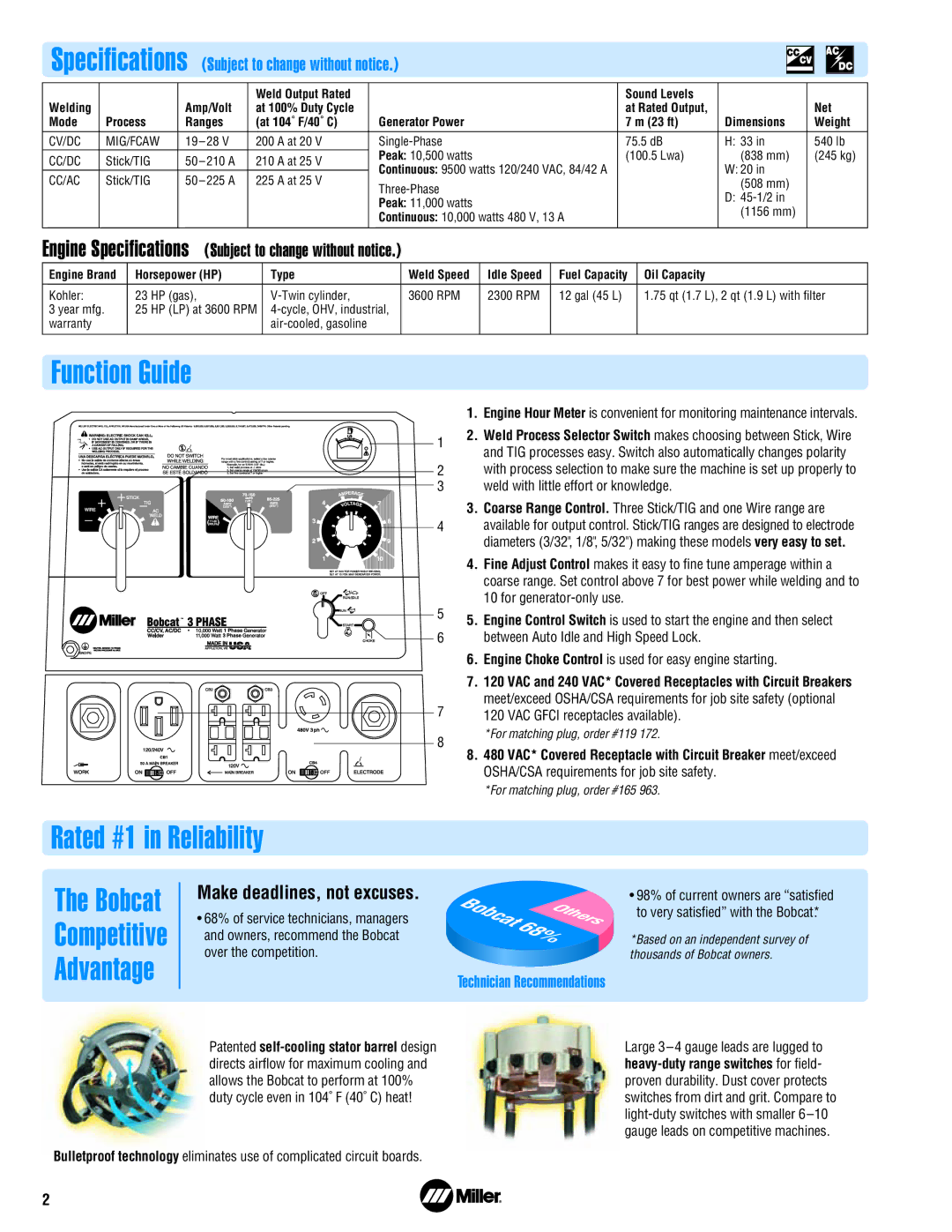

Function Guide

1

2

![]() 3

3

4

5

![]()

![]()

![]()

![]()

![]() 6

6

7 |

8 |

1.Engine Hour Meter is convenient for monitoring maintenance intervals.

2.Weld Process Selector Switch makes choosing between Stick, Wire and TIG processes easy. Switch also automatically changes polarity with process selection to make sure the machine is set up properly to weld with little effort or knowledge.

3.Coarse Range Control. Three Stick/TIG and one Wire range are available for output control. Stick/TIG ranges are designed to electrode diameters (3/32", 1/8", 5/32") making these models very easy to set.

4.Fine Adjust Control makes it easy to fine tune amperage within a coarse range. Set control above 7 for best power while welding and to 10 for

5.Engine Control Switch is used to start the engine and then select between Auto Idle and High Speed Lock.

6.Engine Choke Control is used for easy engine starting.

7.120 VAC and 240 VAC* Covered Receptacles with Circuit Breakers meet/exceed OSHA/CSA requirements for job site safety (optional 120 VAC GFCI receptacles available).

*For matching plug, order #119 172.

8.480 VAC* Covered Receptacle with Circuit Breaker meet/exceed OSHA/CSA requirements for job site safety.

*For matching plug, order #165 963.

Rated #1 in Reliability

The Bobcat

Competitive

Advantage

Make deadlines, not excuses.

•68% of service technicians, managers and owners, recommend the Bobcat over the competition.

Bobcat | Others |

| 68% |

Technician Recommendations

•98% of current owners are “satisfied to very satisfied” with the Bobcat*.

*Based on an independent survey of thousands of Bobcat owners.

Patented

Bulletproof technology eliminates use of complicated circuit boards.

Large

2