COMPOSITE BEARING INFORMATION

FIG. A |

| FIG. B |

|

|

|

Pin Seal

Bearing

Housing

Pin Seal |

|

|

| Bearing | |

|

|

|

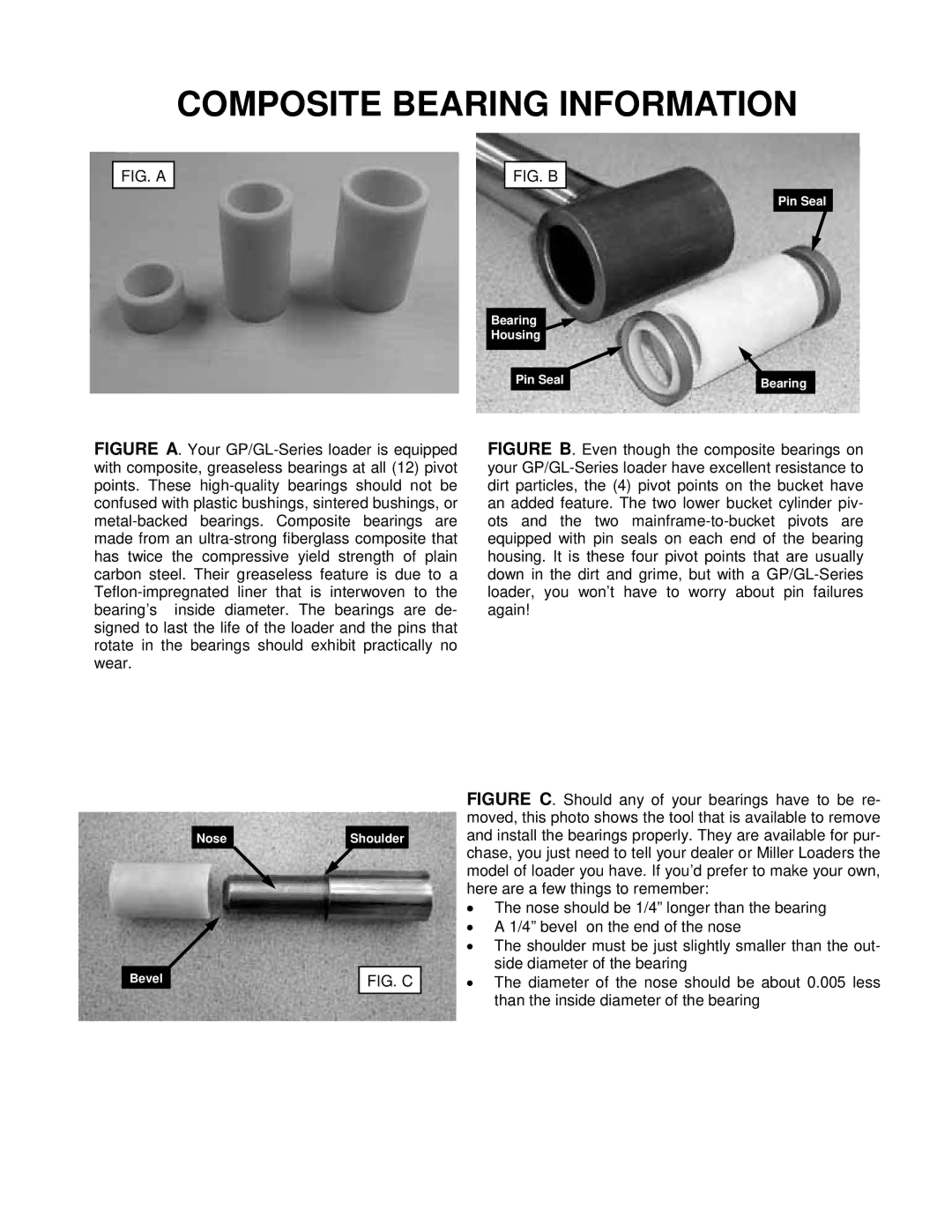

FIGURE A. Your GP/GL-Series loader is equipped with composite, greaseless bearings at all (12) pivot points. These high-quality bearings should not be confused with plastic bushings, sintered bushings, or metal-backed bearings. Composite bearings are made from an ultra-strong fiberglass composite that has twice the compressive yield strength of plain carbon steel. Their greaseless feature is due to a Teflon-impregnated liner that is interwoven to the bearing’s inside diameter. The bearings are de- signed to last the life of the loader and the pins that rotate in the bearings should exhibit practically no wear.

FIGURE B. Even though the composite bearings on your GP/GL-Series loader have excellent resistance to dirt particles, the (4) pivot points on the bucket have an added feature. The two lower bucket cylinder piv- ots and the two mainframe-to-bucket pivots are equipped with pin seals on each end of the bearing housing. It is these four pivot points that are usually down in the dirt and grime, but with a GP/GL-Series loader, you won’t have to worry about pin failures again!

NoseShoulder

Bevel |

| FIG. C |

|

|

|