Selecting Sanding Discs & Grit

Refer to the table below to select the correct type of sanding disc for your job. Generally, use 24 or 36 grit for heavy stock removal; 50, 60, or 80 grit for medium stock removal and 120 grit for finishing. Always begin with a coarse grit, using successively finer grits to obtain the desired finish. See your MILWAUKEE Electric Tool Catalog for a complete list of sanding discs.

Aluminum Oxide

For fast cutting, general purpose discs for most metal jobs. Best for cold-rolled steel, stainless steel or metals requiring tough, fast cutting, long lasting abrasives.

Aluminum Zirconia Bi-Cut

Unique grit pattern is arranged in clusters for fast- er stock removal and cleaning. Ideal for removing paint from cars, boats, etc. without clogging.

Ceramic

Lasts up to 3 times longer than Aluminum Oxide Discs. For general metal working. Ideal for tough jobs.

Installing Backing Pad and Sanding Discs

1.Remove battery pack.

2.Place tool upside down on a level surface. Re- move any accessories from spindle.

Fig. 5

Disc nut

Sanding disc

Backing pad

Spindle

Gear case

3.Slip backing pad onto spindle with flat side away from gear case.

4.Place sanding disc on backing pad and secure assembly to spindle with disc nut.

5.To tighten, press the spindle lock button while turning disc nut clockwise with the spanner wrench provided.

6.To remove backing pad and sanding disc, remove battery pack reverse procedure.

Sanding

1.Use a clamp, vise or other practical means to hold your work, freeing both hands to control your tool.

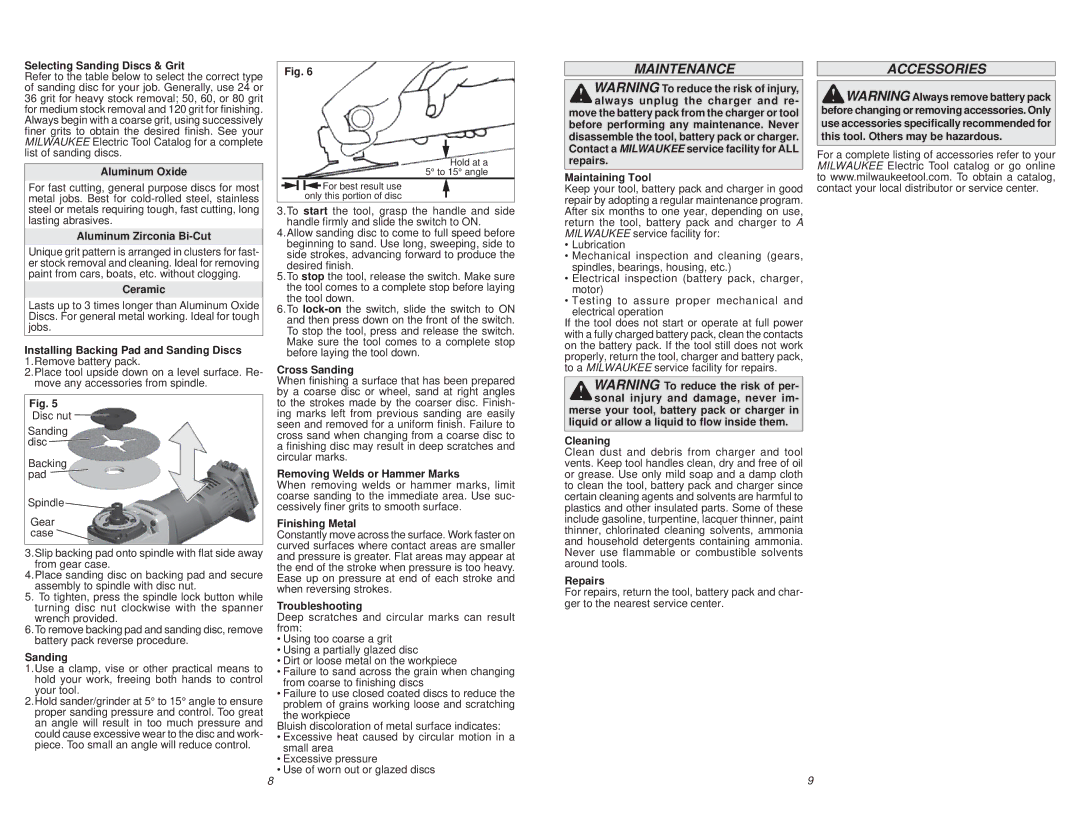

2.Hold sander/grinder at 5° to 15° angle to ensure proper sanding pressure and control. Too great an angle will result in too much pressure and could cause excessive wear to the disc and work- piece. Too small an angle will reduce control.

Fig. 6

Hold at a 5° to 15° angle

For best result use only this portion of disc

For best result use only this portion of disc

3.To start the tool, grasp the handle and side handle firmly and slide the switch to ON.

4.Allow sanding disc to come to full speed before beginning to sand. Use long, sweeping, side to side strokes, advancing forward to produce the desired finish.

5.To stop the tool, release the switch. Make sure the tool comes to a complete stop before laying the tool down.

6.To lock-onthe switch, slide the switch to ON and then press down on the front of the switch. To stop the tool, press and release the switch. Make sure the tool comes to a complete stop before laying the tool down.

Cross Sanding

When finishing a surface that has been prepared by a coarse disc or wheel, sand at right angles to the strokes made by the coarser disc. Finish- ing marks left from previous sanding are easily seen and removed for a uniform finish. Failure to cross sand when changing from a coarse disc to a finishing disc may result in deep scratches and circular marks.

Removing Welds or Hammer Marks

When removing welds or hammer marks, limit coarse sanding to the immediate area. Use suc- cessively finer grits to smooth surface.

Finishing Metal

Constantly move across the surface. Work faster on curved surfaces where contact areas are smaller and pressure is greater. Flat areas may appear at the end of the stroke when pressure is too heavy. Ease up on pressure at end of each stroke and when reversing strokes.

Troubleshooting

Deep scratches and circular marks can result from:

•Using too coarse a grit

•Using a partially glazed disc

•Dirt or loose metal on the workpiece

•Failure to sand across the grain when changing from coarse to finishing discs

•Failure to use closed coated discs to reduce the problem of grains working loose and scratching the workpiece

Bluish discoloration of metal surface indicates:

•Excessive heat caused by circular motion in a small area

•Excessive pressure

•Use of worn out or glazed discs

MAINTENANCE

WARNING To reduce the risk of injury, always unplug the charger and re- move the battery pack from the charger or tool before performing any maintenance. Never disassemble the tool, battery pack or charger. Contact a MILWAUKEE service facility for ALL

repairs.

Maintaining Tool

Keep your tool, battery pack and charger in good repair by adopting a regular maintenance program. After six months to one year, depending on use, return the tool, battery pack and charger to A MILWAUKEE service facility for:

•Lubrication

•Mechanical inspection and cleaning (gears, spindles, bearings, housing, etc.)

•Electrical inspection (battery pack, charger, motor)

•Testing to assure proper mechanical and

electrical operation

If the tool does not start or operate at full power with a fully charged battery pack, clean the contacts on the battery pack. If the tool still does not work properly, return the tool, charger and battery pack, to a MILWAUKEE service facility for repairs.

WARNING To reduce the risk of per- sonal injury and damage, never im- merse your tool, battery pack or charger in

liquid or allow a liquid to flow inside them.

Cleaning

Clean dust and debris from charger and tool vents. Keep tool handles clean, dry and free of oil or grease. Use only mild soap and a damp cloth to clean the tool, battery pack and charger since certain cleaning agents and solvents are harmful to plastics and other insulated parts. Some of these include gasoline, turpentine, lacquer thinner, paint thinner, chlorinated cleaning solvents, ammonia and household detergents containing ammonia. Never use flammable or combustible solvents around tools.

Repairs

For repairs, return the tool, battery pack and char- ger to the nearest service center.

ACCESSORIES

WARNING Always remove battery pack before changing or removing accessories. Only use accessories specifically recommended for this tool. Others may be hazardous.

For a complete listing of accessories refer to your MILWAUKEE Electric Tool catalog or go online to www.milwaukeetool.com. To obtain a catalog, contact your local distributor or service center.