ASSEMBLY

OPERATION

![]() WARNING Recharge only with the char- ger specified for the battery. For specific charging instructions, read the operator’s man- ual supplied with your charger and battery.

WARNING Recharge only with the char- ger specified for the battery. For specific charging instructions, read the operator’s man- ual supplied with your charger and battery.

![]() WARNING Always remove battery pack before changing or removing ac- cessories. Only use accessories specifically recommended for this tool. Others may be hazardous.

WARNING Always remove battery pack before changing or removing ac- cessories. Only use accessories specifically recommended for this tool. Others may be hazardous.

Removing Battery Pack from Tool

Push in the release buttons and pull the battery pack away from the tool.

Inserting Battery Pack into Tool

To insert the battery pack onto the tool, slide the pack onto the body of the tool. Make sure it latches securely into place.

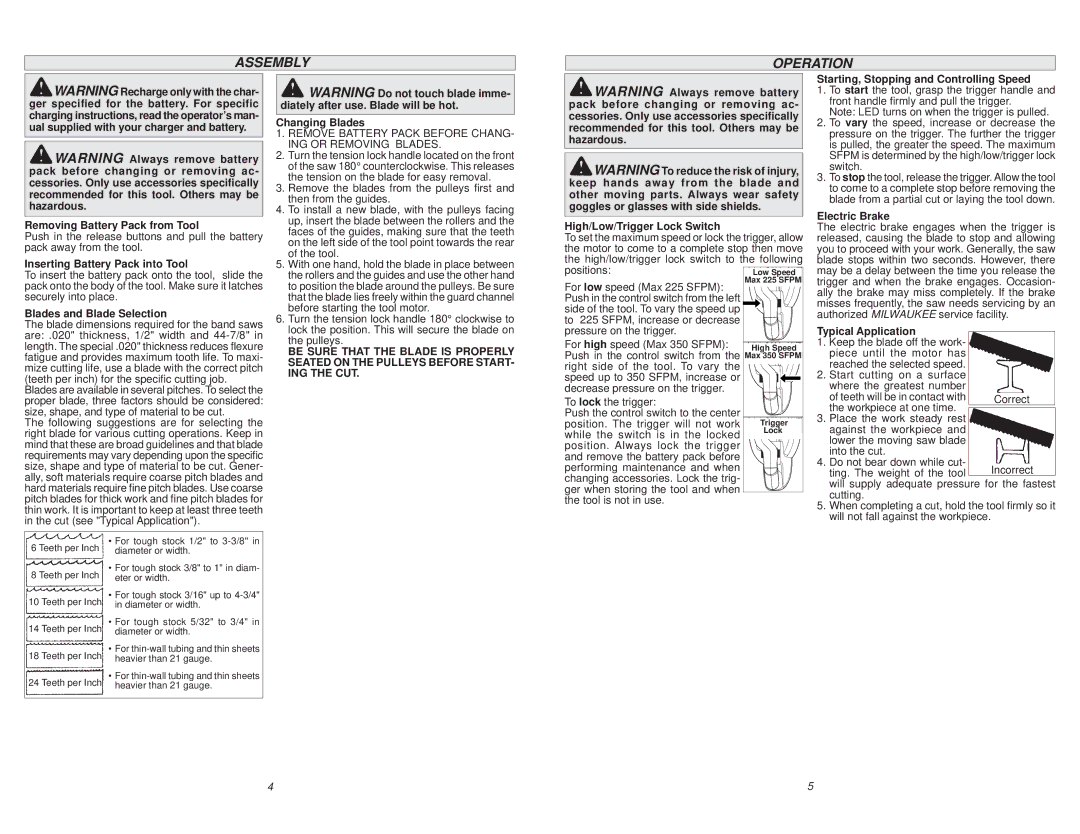

Blades and Blade Selection

The blade dimensions required for the band saws are: .020" thickness, 1/2" width and

Blades are available in several pitches. To select the proper blade, three factors should be considered: size, shape, and type of material to be cut.

The following suggestions are for selecting the right blade for various cutting operations. Keep in mind that these are broad guidelines and that blade requirements may vary depending upon the specific size, shape and type of material to be cut. Gener- ally, soft materials require coarse pitch blades and hard materials require fine pitch blades. Use coarse pitch blades for thick work and fine pitch blades for thin work. It is important to keep at least three teeth in the cut (see "Typical Application").

![]()

![]() WARNING Do not touch blade imme- diately after use. Blade will be hot.

WARNING Do not touch blade imme- diately after use. Blade will be hot.

Changing Blades

1.REMOVE BATTERY PACK BEFORE CHANG- ING OR REMOVING BLADES.

2.Turn the tension lock handle located on the front of the saw 180° counterclockwise. This releases the tension on the blade for easy removal.

3.Remove the blades from the pulleys first and then from the guides.

4.To install a new blade, with the pulleys facing up, insert the blade between the rollers and the faces of the guides, making sure that the teeth on the left side of the tool point towards the rear of the tool.

5.With one hand, hold the blade in place between the rollers and the guides and use the other hand to position the blade around the pulleys. Be sure that the blade lies freely within the guard channel before starting the tool motor.

6.Turn the tension lock handle 180° clockwise to lock the position. This will secure the blade on the pulleys.

BE SURE THAT THE BLADE IS PROPERLY SEATED ON THE PULLEYS BEFORE START- ING THE CUT.

![]() WARNING Always remove battery pack before changing or removing ac- cessories. Only use accessories specifically recommended for this tool. Others may be hazardous.

WARNING Always remove battery pack before changing or removing ac- cessories. Only use accessories specifically recommended for this tool. Others may be hazardous.

![]() WARNING To reduce the risk of injury, keep hands away from the blade and other moving parts. Always wear safety goggles or glasses with side shields.

WARNING To reduce the risk of injury, keep hands away from the blade and other moving parts. Always wear safety goggles or glasses with side shields.

High/Low/Trigger Lock Switch

To set the maximum speed or lock the trigger, allow the motor to come to a complete stop then move

the high/low/trigger lock switch to the following | |

positions: | Low Speed |

For low speed (Max 225 SFPM): | Max 225 SFPM |

| |

Push in the control switch from the left |

|

side of the tool. To vary the speed up |

|

to 225 SFPM, increase or decrease |

|

pressure on the trigger. |

|

For high speed (Max 350 SFPM): | High Speed |

Push in the control switch from the | Max 350 SFPM |

right side of the tool. To vary the |

|

speed up to 350 SFPM, increase or |

|

decrease pressure on the trigger. |

|

To lock the trigger: |

|

Push the control switch to the center |

|

position. The trigger will not work | Trigger |

while the switch is in the locked | Lock |

position. Always lock the trigger |

|

and remove the battery pack before |

|

performing maintenance and when |

|

changing accessories. Lock the trig- |

|

ger when storing the tool and when |

|

the tool is not in use. |

|

Starting, Stopping and Controlling Speed

1.To start the tool, grasp the trigger handle and front handle firmly and pull the trigger.

Note: LED turns on when the trigger is pulled.

2.To vary the speed, increase or decrease the pressure on the trigger. The further the trigger is pulled, the greater the speed. The maximum SFPM is determined by the high/low/trigger lock switch.

3.To stop the tool, release the trigger. Allow the tool to come to a complete stop before removing the blade from a partial cut or laying the tool down.

Electric Brake

The electric brake engages when the trigger is released, causing the blade to stop and allowing you to proceed with your work. Generally, the saw blade stops within two seconds. However, there may be a delay between the time you release the trigger and when the brake engages. Occasion- ally the brake may miss completely. If the brake misses frequently, the saw needs servicing by an authorized MILWAUKEE service facility.

Typical Application

1. | Keep the blade off the work- |

|

| piece until the motor has |

|

2. | reached the selected speed. |

|

Start cutting on a surface |

| |

| where the greatest number |

|

| of teeth will be in contact with | Correct |

| the workpiece at one time. |

|

|

|

3.Place the work steady rest against the workpiece and lower the moving saw blade into the cut.

4.Do not bear down while cut-

ting. The weight of the tool Incorrect

will supply adequate pressure for the fastest cutting.

5.When completing a cut, hold the tool firmly so it will not fall against the workpiece.

6 Teeth per Inch

8 Teeth per Inch

10 Teeth per Inch

14 Teeth per Inch

18 Teeth per Inch

24 Teeth per Inch

•For tough stock 1/2" to

•For tough stock 3/8" to 1" in diam- eter or width.

•For tough stock 3/16" up to

•For tough stock 5/32" to 3/4" in diameter or width.

•For

•For

4 | 5 |