2.Release collar and the spring loaded mechanism will clamp the blade firmly in place.

3.Twist collar in the opposite direction of the arrow to ensure that the blade is locked into the clamp.

4.Tug on blade to make sure it is securely locked in place.

5.To remove a blade, twist collar in the direction of the arrow while pulling on the blade. Be careful when handling hot blades.

Quik-Lok® Blade Clamp Maintenance

•Periodically clean dust and debris from the

•If the collar resists twisting, twist the collar back and forth to shake debris loose.

•Periodically lubricate

Removing broken blades from the Quik- Lok® Blade Clamp

•Remove battery pack before removing blades.

•Broken blades can be removed by the following methods.

•Point the tool downward, twist the collar, and shake the tool up and down (DO NOT turn the tool on while your fingers are holding the blade clamp open). The shank of the broken blade should drop out of the clamp.

•If shaking the tool doesn't work...

In most cases, a corner of the broken blade will extend beyond the blade clamp. Simply twist the collar and pull the broken blade out of the clamp by this corner.

•If the broken stub doesn't extend far enough to be grabbed by its corner, use a thin blade with small teeth (such as a metal cutting blade) to hook the blade that is jammed in the clamp while twist- ing the collar and pull it out.

Adjusting the Pivot Shoe

The shoe can be adjusted forward or back- ward to six positions to take advantage of the unused portion of the blade or for special jobs requiring low blade clearance.

![]() WARNING

WARNING

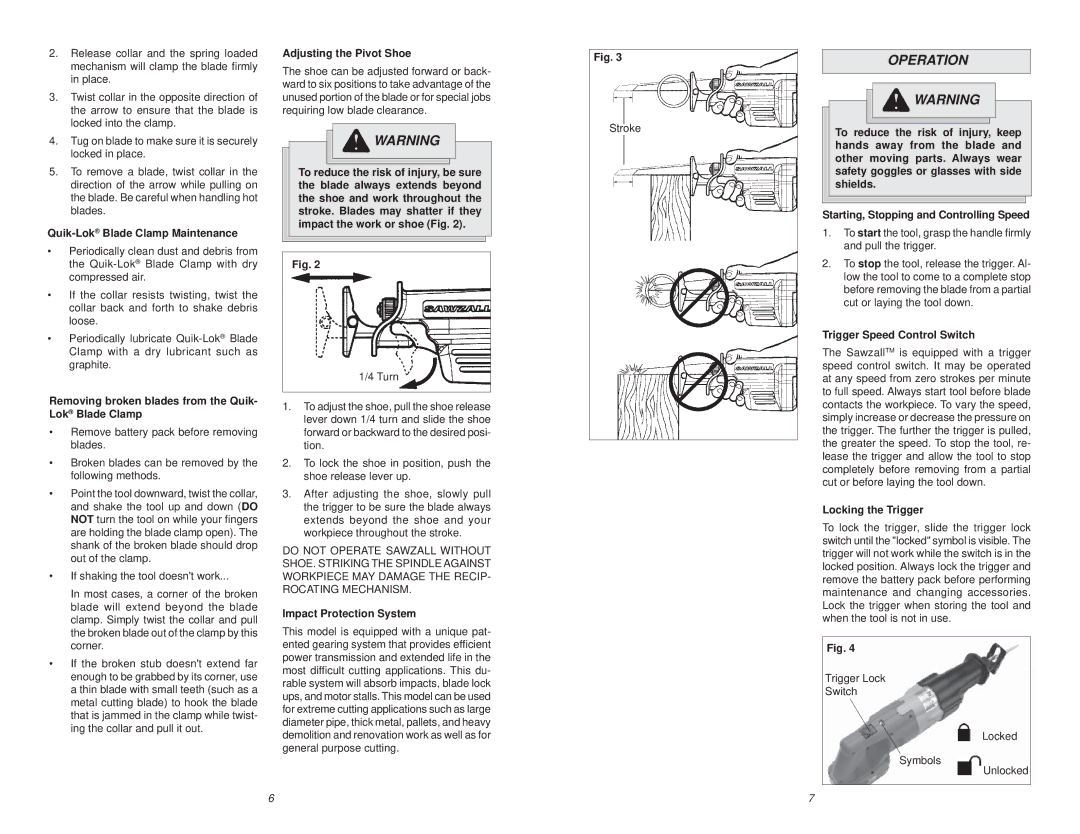

To reduce the risk of injury, be sure the blade always extends beyond the shoe and work throughout the stroke. Blades may shatter if they impact the work or shoe (Fig. 2).

Fig. 2

1/4 Turn

1.To adjust the shoe, pull the shoe release lever down 1/4 turn and slide the shoe forward or backward to the desired posi- tion.

2.To lock the shoe in position, push the shoe release lever up.

3.After adjusting the shoe, slowly pull the trigger to be sure the blade always extends beyond the shoe and your workpiece throughout the stroke.

DO NOT OPERATE SAWZALL WITHOUT SHOE. STRIKING THE SPINDLE AGAINST WORKPIECE MAY DAMAGE THE RECIP- ROCATING MECHANISM.

Impact Protection System

This model is equipped with a unique pat- ented gearing system that provides efficient power transmission and extended life in the most difficult cutting applications. This du- rable system will absorb impacts, blade lock ups, and motor stalls. This model can be used for extreme cutting applications such as large diameter pipe, thick metal, pallets, and heavy demolition and renovation work as well as for general purpose cutting.

Fig. 3

Stroke

OPERATION

![]() WARNING

WARNING

To reduce the risk of injury, keep hands away from the blade and other moving parts. Always wear safety goggles or glasses with side shields.

Starting, Stopping and Controlling Speed

1.To start the tool, grasp the handle firmly and pull the trigger.

2.To stop the tool, release the trigger. Al- low the tool to come to a complete stop before removing the blade from a partial cut or laying the tool down.

Trigger Speed Control Switch

The SawzallTM is equipped with a trigger speed control switch. It may be operated at any speed from zero strokes per minute to full speed. Always start tool before blade contacts the workpiece. To vary the speed, simply increase or decrease the pressure on the trigger. The further the trigger is pulled, the greater the speed. To stop the tool, re- lease the trigger and allow the tool to stop completely before removing from a partial cut or before laying the tool down.

Locking the Trigger

To lock the trigger, slide the trigger lock switch until the "locked" symbol is visible. The trigger will not work while the switch is in the locked position. Always lock the trigger and remove the battery pack before performing maintenance and changing accessories. Lock the trigger when storing the tool and when the tool is not in use.

Fig. 4

Trigger Lock

Switch

Locked

Symbols

Unlocked

6 | 7 |