2401-20 specifications

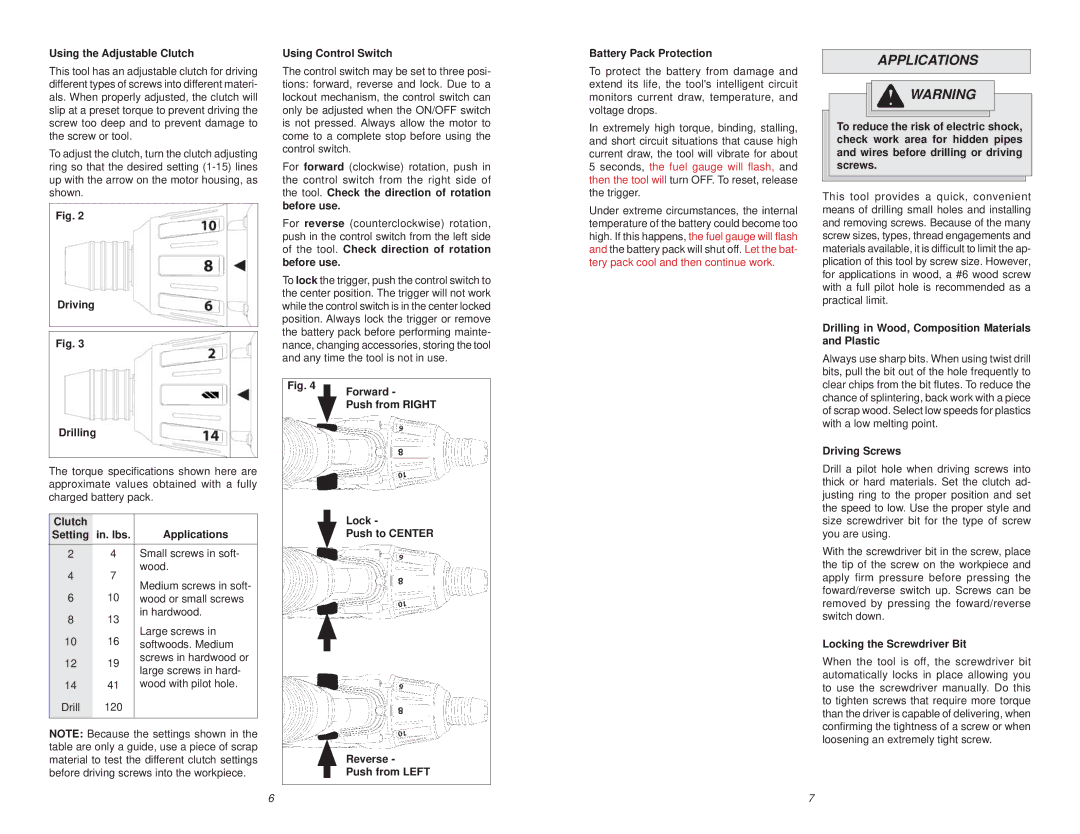

Milwaukee 2401-20 represents a significant addition to Milwaukee's renowned line of power tools, specifically designed for professionals who demand durability and high performance in their equipment. This model, a cordless M12 Drill/Driver, exhibits a balance between compactness and power, making it a versatile asset for various tasks in different settings, such as construction sites and home improvement projects.At the heart of the Milwaukee 2401-20 is its powerful brushless motor, which provides outstanding efficiency and runtime. The brushless technology enhances the tool's lifespan and reduces the need for maintenance, allowing professionals to focus on their work without worrying about tool performance degradation over time. With a maximum torque of up to 250 inch-pounds, this drill/driver can handle a wide range of fastening applications, from plastic and wood to metal, ensuring it can tackle everyday jobs efficiently.

One of the most impressive features of the Milwaukee 2401-20 is its compact design. Weighing in at only 2.2 pounds and measuring just 6.6 inches in length, it easily fits into tight spaces, making it ideal for overhead or cramped conditions where larger tools might struggle. This portability does not come at the cost of power, proving that Milwaukee has successfully combined size with performance.

Functionality is further enhanced with its variable speed settings, providing users with the flexibility to adjust from 0 to 1,600 RPM, allowing for precise control over the speed and torque output according to the specific application. An integrated LED light illuminates the work area, ensuring visibility even in dark or confined spaces, which is crucial for professional tradespeople who often work in varied environments.

Another standout characteristic of the Milwaukee 2401-20 is its compatibility with the M12 battery system. This system allows for seamless interchangeability with other M12 tools, making the drill/driver a part of a comprehensive, efficient toolkit. The battery also boasts a fuel gauge, providing users with real-time information about remaining power to prevent interruptions during critical tasks.

In summary, the Milwaukee 2401-20 combines a compact design, powerful performance, and advanced technology, making it an essential tool for both professionals and DIY enthusiasts. Its brushless motor, variable speed control, and compatibility with the M12 battery system make it a reliable choice that stands out in the crowded market of cordless power tools. Whether engaging in heavy-duty applications or simple home projects, this drill/driver delivers the power and precision needed to get the job done.