EXTENSION CORDS

TOOL ASSEMBLY

Grounded tools require a three wire exten- sion cord. Double insulated tools can use either a two or three wire extension cord. As the distance from the supply outlet increases, you must use a heavier gauge extension cord. Using extension cords with inadequately sized wire causes a serious drop in voltage, resulting in loss of power and possible tool damage. Refer to the table shown to determine the required minimum wire size.

The smaller the gauge number of the wire, the greater the capacity of the cord. For ex- ample, a 14 gauge cord can carry a higher current than a 16 gauge cord. When using more than one extension cord to make up the total length, be sure each cord contains at least the minimum wire size required. If you are using one extension cord for more than one tool, add the nameplate amperes and use the sum to determine the required minimum wire size.

Guidelines for Using Extension Cords

•If you are using an extension cord out- doors, be sure it is marked with the suffix

•Be sure your extension cord is prop- erly wired and in good electrical condition. Always replace a damaged extension cord or have it repaired by a qualified person before using it.

•Protect your extension cords from sharp objects, excessive heat and

damp or wet areas.

Recommended Minimum Wire Gauge

for Extension Cords*

Nameplate | Extension Cord Length | |||||

Amperes | 25' | 50' | 75' | 100' | 150' | |

|

|

|

|

|

| |

0 - 2.0 | 18 | 18 | 18 | 18 | 16 | |

2.1 | - 3.4 | 18 | 18 | 18 | 16 | 14 |

3.5 | - 5.0 | 18 | 18 | 16 | 14 | 12 |

5.1 | - 7.0 | 18 | 16 | 14 | 12 | 12 |

7.1 - 12.0 | 16 | 14 | 12 | 10 |

| |

12.1 | - 16.0 | 14 | 12 | 10 |

|

|

16.1 | - 20.0 | 12 | 10 |

|

|

|

|

|

|

|

|

|

|

*Based on limiting the line voltage drop to five volts at 150% of the rated amperes.

![]()

![]()

![]() WARNING

WARNING

To reduce the risk of injury, always unplug tool before attaching or removing accessories or making adjustments. Use only specifically recommended accessories. Others may be hazardous.

Installing Bits into Keyed Chucks (Fig.1)

Fig. 1

1. | Unplug tool. |

2. | Open the chuck jaws wide enough to |

| insert the bit. Be sure the bit shank and |

| chuck jaws are clean. Dirt particles may |

| prevent the bit from lining up properly. |

3. | Insert the bit into the chuck. Center the |

| bit in the chuck jaws and lift it about 1/16" |

Pipe Handle

The pipe handle may be used on either side of the tool. Thread pipe handle into one of the threaded holes in the motor housing.

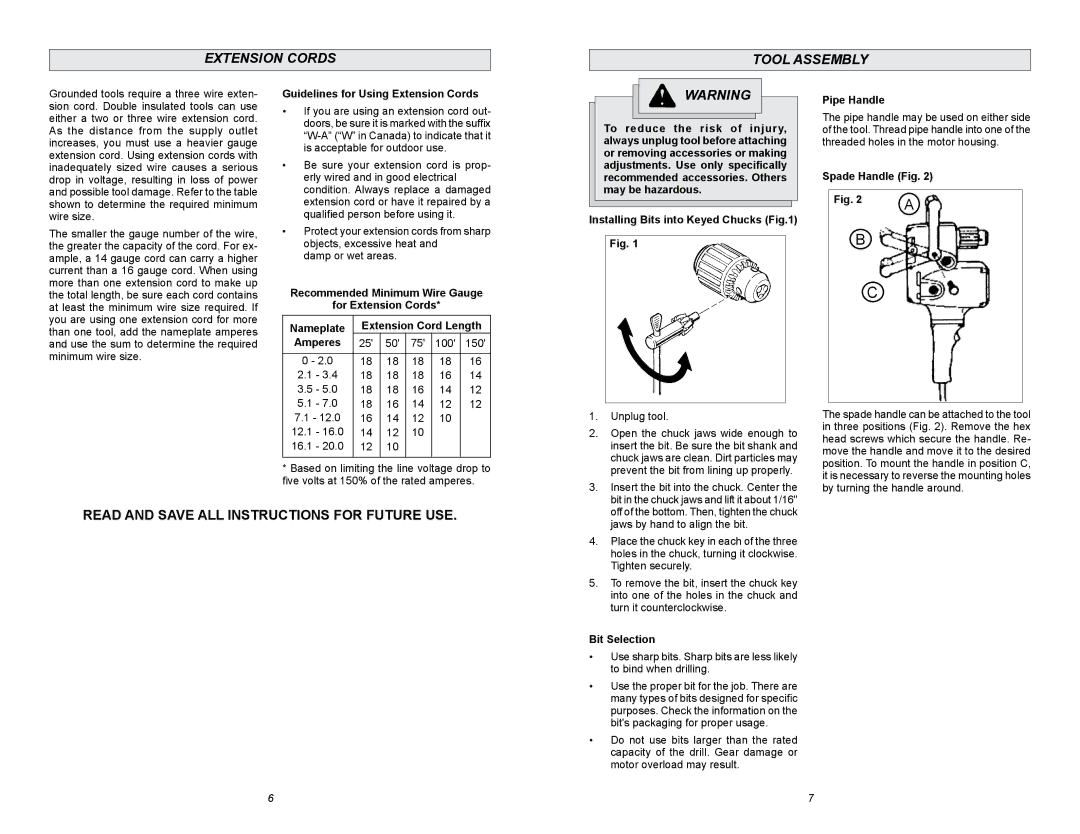

Spade Handle (Fig. 2)

Fig. 2 | A |

B

C

The spade handle can be attached to the tool in three positions (Fig. 2). Remove the hex head screws which secure the handle. Re- move the handle and move it to the desired position. To mount the handle in position C, it is necessary to reverse the mounting holes by turning the handle around.

READ AND SAVE ALL INSTRUCTIONS FOR FUTURE USE.

6

| off of the bottom. Then, tighten the chuck |

| jaws by hand to align the bit. |

4. | Place the chuck key in each of the three |

| holes in the chuck, turning it clockwise. |

| Tighten securely. |

5. | To remove the bit, insert the chuck key |

| into one of the holes in the chuck and |

| turn it counterclockwise. |

Bit Selection

•Use sharp bits. Sharp bits are less likely to bind when drilling.

•Use the proper bit for the job. There are many types of bits designed for specific purposes. Check the information on the bit's packaging for proper usage.

•Do not use bits larger than the rated capacity of the drill. Gear damage or motor overload may result.

7