Selecting Wheels

Grinding is the cutting action of thousands of abrasive grains on the face of a grinding wheel. When grinding metals such as steel and iron, choose an aluminum oxide grinding wheel. Select a silicon carbide grinding wheel for stone and concrete. Use cotton reinforced wheels for

Type 27 reinforced 1/8"

![]()

![]()

![]() WARNING!

WARNING!

To reduce the risk of injury when grinding:

•ALWAYS hold the tool firmly with both hands using the handles provided; before and during grinding

•NEVER allow the wheel to bind

•NEVER use a wheel that has been dropped

•NEVER bang grinding wheel onto work

•NEVER grind without proper safety equipment

![]()

![]()

![]() WARNING!

WARNING!

To reduce the risk of injury when grinding, ALWAYS use the proper guard. ALWAYS properly install the guard.

Grinding (Fig. 9 & 10)

1. Depending on your job, position the guard to provide maximum protec- tion for the operator (Fig. 9).

Fig. 9

1 Operator's Zones

1

1

1

2.If you have just installed a grinding wheel or are just beginning a period of work, test the wheel by letting it spin for one minute before applying it to the workpiece.

NOTE:

3.Firmly grasp rear handle and side handle before starting and while using tool. Allow wheel to come to full speed before starting to grind.

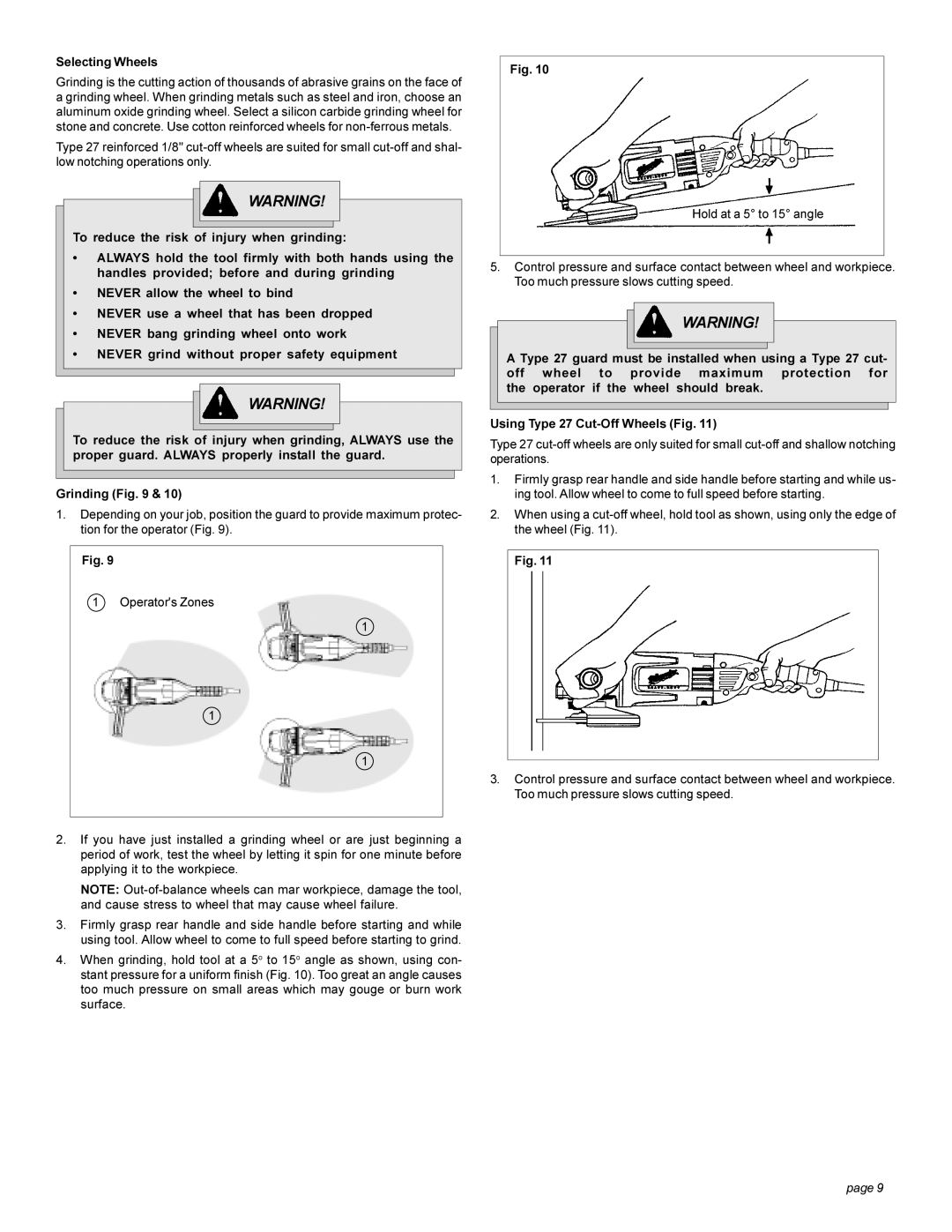

4.When grinding, hold tool at a 5o to 15o angle as shown, using con- stant pressure for a uniform finish (Fig. 10). Too great an angle causes too much pressure on small areas which may gouge or burn work surface.

Fig. 10

Hold at a 5° to 15° angle

5.Control pressure and surface contact between wheel and workpiece. Too much pressure slows cutting speed.

![]()

![]()

![]() WARNING!

WARNING!

A Type 27 guard must be installed when using a Type 27 cut- off wheel to provide maximum protection for the operator if the wheel should break.

Using Type 27

Type 27

1.Firmly grasp rear handle and side handle before starting and while us- ing tool. Allow wheel to come to full speed before starting.

2.When using a

Fig. 11

3.Control pressure and surface contact between wheel and workpiece. Too much pressure slows cutting speed.

page 9