Double Insulated Tools:

Tools with Two Prong Plugs

Tools marked "Double Insulated" do not require grounding. They have a special double insula- tion system which satisfies OSHA requirements and complies with the applicable standards

of Underwriters Laboratories, |

|

Inc., the Canadian Standard |

|

Association and the National |

|

Electrical Code. Double Insulated |

|

tools may be used in either of |

|

the 120 volt outlets shown in | Fig. B Fig. C |

Figures B and C. |

EXTENSION CORDS

Grounded tools require a three wire extension cord. Double insulated tools can use either a two or three wire extension cord. As the distance from the supply outlet increases, you must use a heavier gauge extension cord. Using extension cords with inadequately sized wire causes a serious drop in voltage, resulting in loss of power and possible tool damage. Refer to the table shown to determine the required minimum wire size.

The smaller the gauge number of the wire, the greater the capacity of the cord. For example, a 14 gauge cord can carry a higher current than a 16 gauge cord. When using more than one extension cord to make up the total length, be sure each cord contains at least the minimum wire size required. If you are using one extension cord for more than one tool, add the nameplate amperes and use the sum to determine the required minimum wire size.

Guidelines for Using Extension Cords

•If you are using an extension cord outdoors, be sure it is marked with the suffix

•Be sure your extension cord is properly wired and in good electrical condition. Always replace a damaged extension cord or have it repaired by a qualified person before using it.

•Protect your extension cords from sharp objects, excessive heat and damp or wet areas.

Recommended Minimum Wire Gauge

for Extension Cords*

Nameplate | Extension Cord Length | ||||

Amperes |

|

|

|

|

|

25' | 50' | 75' | 100' | 150' | |

0 - 2.0 | 18 | 18 | 18 | 18 | 16 |

2.1 - 3.4 | 18 | 18 | 18 | 16 | 14 |

3.5 - 5.0 | 18 | 18 | 16 | 14 | 12 |

5.1 - 7.0 | 18 | 16 | 14 | 12 | 12 |

7.1- 12.0 16 14 12 10 12.1 - 16.0 14 12 10

16.1 - 20.0 12 10

*Based on limiting the line voltage drop to five volts at 150% of the rated amperes.

READ AND SAVE ALL

INSTRUCTIONS FOR

FUTURE USE.

ASSEMBLY

WARNING To reduce the risk of injury, always unplug tool before attaching or removing accessories or making adjust-

ments. Use only specifically recommended accessories. Others may be hazardous.

Installing Side Handle

The side handle may be installed on either side of the gear case. Position the side handle in the location which offers best control and guard protec- tion. To install, thread side handle into side handle socket and tighten securely.

WARNING To reduce the risk of injury when grinding:

•ALWAYS use the proper guard.

•ALWAYS properly install the guard.

•ALWAYS hold the tool firmly with both hands using the handles provided before and during grinding.

•NEVER use a wheel that has been dropped.

•NEVER bang grinding disc onto work.

•NEVER grind without proper safety equipment.

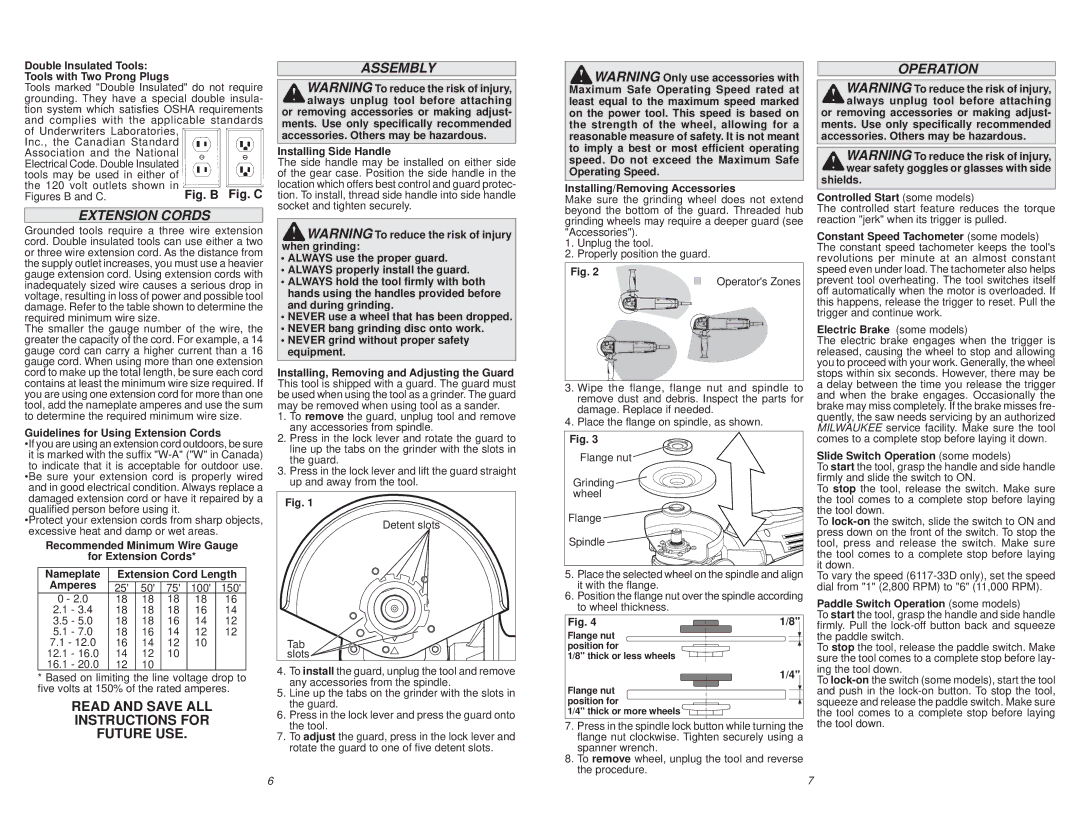

Installing, Removing and Adjusting the Guard This tool is shipped with a guard. The guard must be used when using the tool as a grinder. The guard may be removed when using tool as a sander.

1.To remove the guard, unplug tool and remove any accessories from spindle.

2.Press in the lock lever and rotate the guard to line up the tabs on the grinder with the slots in the guard.

3.Press in the lock lever and lift the guard straight up and away from the tool.

Fig. 1

Detent slots

Tab slots

4.To install the guard, unplug the tool and remove any accessories from the spindle.

5.Line up the tabs on the grinder with the slots in the guard.

6.Press in the lock lever and press the guard onto the tool.

7.To adjust the guard, press in the lock lever and rotate the guard to one of five detent slots.

WARNING Only use accessories with Maximum Safe Operating Speed rated at least equal to the maximum speed marked on the power tool. This speed is based on the strength of the wheel, allowing for a reasonable measure of safety. It is not meant to imply a best or most efficient operating speed. Do not exceed the Maximum Safe Operating Speed.

Installing/Removing Accessories

Make sure the grinding wheel does not extend beyond the bottom of the guard. Threaded hub grinding wheels may require a deeper guard (see "Accessories").

1.Unplug the tool.

2.Properly position the guard.

Fig. 2

Operator's Zones

3.Wipe the flange, flange nut and spindle to remove dust and debris. Inspect the parts for damage. Replace if needed.

4.Place the flange on spindle, as shown.

Fig. 3

Flange nut![]()

![]()

![]()

![]()

![]()

Grinding ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() wheel

wheel ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Flange ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Spindle ![]()

![]()

![]()

![]()

![]()

![]()

5.Place the selected wheel on the spindle and align it with the flange.

6.Position the flange nut over the spindle according to wheel thickness.

Fig. 4 | 1/8" |

Flange nut position for

1/8" thick or less wheels

1/4"

Flange nut position for

1/4" thick or more wheels![]()

7.Press in the spindle lock button while turning the flange nut clockwise. Tighten securely using a spanner wrench.

8.To remove wheel, unplug the tool and reverse the procedure.

OPERATION

WARNING To reduce the risk of injury, always unplug tool before attaching or removing accessories or making adjust-

ments. Use only specifically recommended accessories. Others may be hazardous.

WARNING To reduce the risk of injury, wear safety goggles or glasses with side

shields.

Controlled Start (some models)

The controlled start feature reduces the torque reaction "jerk" when its trigger is pulled.

Constant Speed Tachometer (some models) The constant speed tachometer keeps the tool's revolutions per minute at an almost constant speed even under load. The tachometer also helps prevent tool overheating. The tool switches itself off automatically when the motor is overloaded. If this happens, release the trigger to reset. Pull the trigger and continue work.

Electric Brake (some models)

The electric brake engages when the trigger is released, causing the wheel to stop and allowing you to proceed with your work. Generally, the wheel stops within six seconds. However, there may be a delay between the time you release the trigger and when the brake engages. Occasionally the brake may miss completely. If the brake misses fre- quently, the saw needs servicing by an authorized MILWAUKEE service facility. Make sure the tool comes to a complete stop before laying it down.

Slide Switch Operation (some models)

To start the tool, grasp the handle and side handle firmly and slide the switch to ON.

To stop the tool, release the switch. Make sure the tool comes to a complete stop before laying the tool down.

To

To vary the speed

Paddle Switch Operation (some models)

To start the tool, grasp the handle and side handle firmly. Pull the

To stop the tool, release the paddle switch. Make sure the tool comes to a complete stop before lay- ing the tool down.

To

6 | 7 |