OPERATION

WARNING!

To reduce the risk of injury, always unplug tool before attaching or removing accessories. Use only specifically recommended accessories. Others may be hazardous.

6.Press in the spindle lock button while using the open end wrench provided to tighten the hex bolt (clockwise).

NOTE: Tighten the bolt firmly enough to flatten the spring washer, but do not use excessive pressure. Overtightening the bolt may damage the wheel and flanges.

7.Allow the moveable portion of the guard to return to its original position.

Using the Hold-Down Chain

This tool is equipped with a

WARNING!

To reduce the risk of injury, use only the proper wheel made for this machine. DO NOT USE ANY TYPE OF SAW BLADE.

Removing and Installing

The

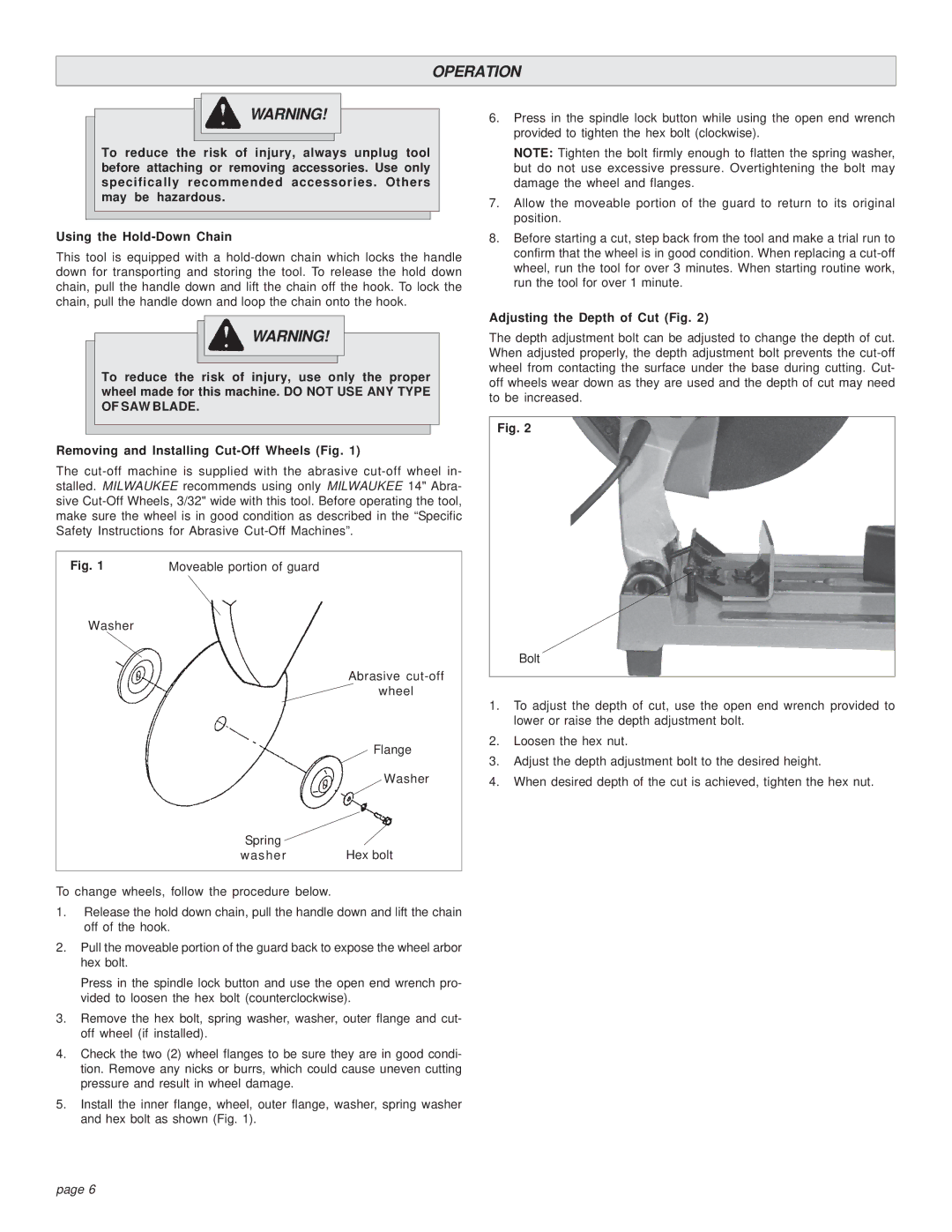

Fig. 1 | Moveable portion of guard |

Washer

Abrasive

wheel

Flange

Washer

Spring |

|

washer | Hex bolt |

To change wheels, follow the procedure below.

1.Release the hold down chain, pull the handle down and lift the chain off of the hook.

2.Pull the moveable portion of the guard back to expose the wheel arbor hex bolt.

Press in the spindle lock button and use the open end wrench pro- vided to loosen the hex bolt (counterclockwise).

3.Remove the hex bolt, spring washer, washer, outer flange and cut- off wheel (if installed).

4.Check the two (2) wheel flanges to be sure they are in good condi- tion. Remove any nicks or burrs, which could cause uneven cutting pressure and result in wheel damage.

5.Install the inner flange, wheel, outer flange, washer, spring washer and hex bolt as shown (Fig. 1).

8.Before starting a cut, step back from the tool and make a trial run to confirm that the wheel is in good condition. When replacing a

Adjusting the Depth of Cut (Fig. 2)

The depth adjustment bolt can be adjusted to change the depth of cut. When adjusted properly, the depth adjustment bolt prevents the

Fig. 2

Bolt

1.To adjust the depth of cut, use the open end wrench provided to lower or raise the depth adjustment bolt.

2.Loosen the hex nut.

3.Adjust the depth adjustment bolt to the desired height.

4.When desired depth of the cut is achieved, tighten the hex nut.

page 6