GROUNDING

WARNING Improperly connecting the grounding wire can result in the risk of elec- tric shock. Check with a qualified electrician if you are in doubt as to whether the outlet is properly grounded. Do not modify the plug provided with the tool. Never remove the grounding prong from the plug. Do not use the tool if the cord or plug is damaged. If damaged, have it repaired by a MILWAUKEE service facility before use. If the plug will not fit the outlet, have a proper outlet installed by a qualified electrician.

WARNING Improperly connecting the grounding wire can result in the risk of elec- tric shock. Check with a qualified electrician if you are in doubt as to whether the outlet is properly grounded. Do not modify the plug provided with the tool. Never remove the grounding prong from the plug. Do not use the tool if the cord or plug is damaged. If damaged, have it repaired by a MILWAUKEE service facility before use. If the plug will not fit the outlet, have a proper outlet installed by a qualified electrician.

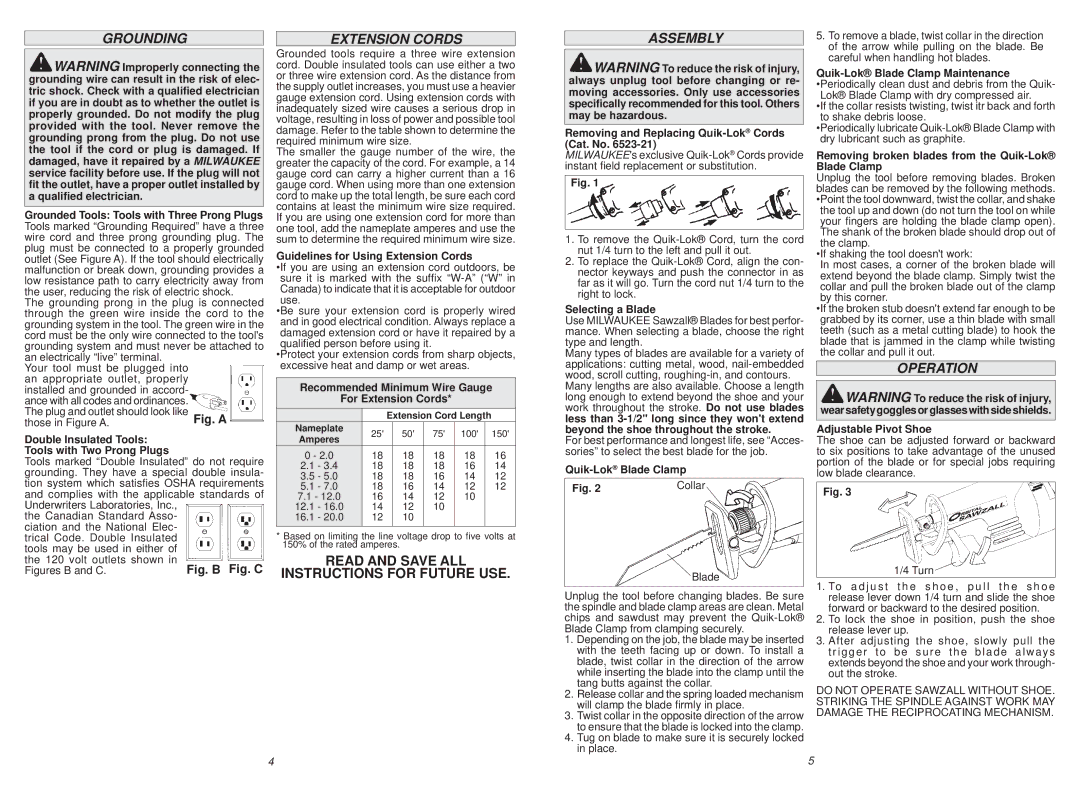

Grounded Tools: Tools with Three Prong Plugs Tools marked “Grounding Required” have a three wire cord and three prong grounding plug. The plug must be connected to a properly grounded outlet (See Figure A). If the tool should electrically malfunction or break down, grounding provides a low resistance path to carry electricity away from the user, reducing the risk of electric shock.

The grounding prong in the plug is connected through the green wire inside the cord to the grounding system in the tool. The green wire in the cord must be the only wire connected to the tool's grounding system and must never be attached to

an electrically “live” terminal. | |

Your tool must be plugged into | |

an appropriate outlet, properly | |

installed and grounded in accord- | |

ance with all codes and ordinances. | |

The plug and outlet should look like | Fig. A |

those in Figure A. |

Double Insulated Tools:

Tools with Two Prong Plugs

Tools marked “Double Insulated” do not require grounding. They have a special double insula- tion system which satisfies OSHA requirements and complies with the applicable standards of

Underwriters Laboratories, Inc., | |

the Canadian Standard Asso- | |

ciation and the National Elec- | |

trical Code. Double Insulated | |

tools may be used in either of | |

the 120 volt outlets shown in | Fig. B Fig. C |

Figures B and C. |

EXTENSION CORDS

Grounded tools require a three wire extension cord. Double insulated tools can use either a two or three wire extension cord. As the distance from the supply outlet increases, you must use a heavier gauge extension cord. Using extension cords with inadequately sized wire causes a serious drop in voltage, resulting in loss of power and possible tool damage. Refer to the table shown to determine the required minimum wire size.

The smaller the gauge number of the wire, the greater the capacity of the cord. For example, a 14 gauge cord can carry a higher current than a 16 gauge cord. When using more than one extension cord to make up the total length, be sure each cord contains at least the minimum wire size required. If you are using one extension cord for more than one tool, add the nameplate amperes and use the sum to determine the required minimum wire size.

Guidelines for Using Extension Cords

•If you are using an extension cord outdoors, be sure it is marked with the suffix “W-A” (“W” in Canada) to indicate that it is acceptable for outdoor use.

•Be sure your extension cord is properly wired and in good electrical condition. Always replace a damaged extension cord or have it repaired by a qualified person before using it.

•Protect your extension cords from sharp objects, excessive heat and damp or wet areas.

Recommended Minimum Wire Gauge

For Extension Cords*

Extension Cord Length

Nameplate 25' 50' 75' 100' 150'

Amperes

0 - 2.0 18 18 18 18 16

2.1 - 3.4 18 18 18 16 14

3.5 - 5.0 18 18 16 14 12

5.1 - 7.0 18 16 14 12 12

7.1 - 12.0 16 14 12 10

12.1 - 16.0 14 12 10

16.1 - 20.0 12 10

*Based on limiting the line voltage drop to five volts at 150% of the rated amperes.

READ AND SAVE ALL

INSTRUCTIONS FOR FUTURE USE.

ASSEMBLY

WARNING To reduce the risk of injury, always unplug tool before changing or re- moving accessories. Only use accessories specifically recommended for this tool. Others may be hazardous.

WARNING To reduce the risk of injury, always unplug tool before changing or re- moving accessories. Only use accessories specifically recommended for this tool. Others may be hazardous.

Removing and Replacing Quik-Lok®Cords (Cat. No. 6523-21)

MILWAUKEE's exclusive Quik-Lok®Cords provide instant field replacement or substitution.

Fig. 1

1.To remove the Quik-Lok® Cord, turn the cord nut 1/4 turn to the left and pull it out.

2.To replace the Quik-Lok® Cord, align the con- nector keyways and push the connector in as far as it will go. Turn the cord nut 1/4 turn to the right to lock.

Selecting a Blade

Use MILWAUKEE Sawzall® Blades for best perfor- mance. When selecting a blade, choose the right type and length.

Many types of blades are available for a variety of applications: cutting metal, wood, nail-embedded wood, scroll cutting, roughing-in, and contours.

Many lengths are also available. Choose a length long enough to extend beyond the shoe and your work throughout the stroke. Do not use blades less than 3-1/2" long since they won't extend beyond the shoe throughout the stroke.

For best performance and longest life, see “Acces- sories” to select the best blade for the job.

Quik-Lok®Blade Clamp

Blade

Blade

Unplug the tool before changing blades. Be sure the spindle and blade clamp areas are clean. Metal chips and sawdust may prevent the Quik-Lok® Blade Clamp from clamping securely.

1.Depending on the job, the blade may be inserted with the teeth facing up or down. To install a blade, twist collar in the direction of the arrow while inserting the blade into the clamp until the tang butts against the collar.

2.Release collar and the spring loaded mechanism will clamp the blade firmly in place.

3.Twist collar in the opposite direction of the arrow to ensure that the blade is locked into the clamp.

4.Tug on blade to make sure it is securely locked in place.

5.To remove a blade, twist collar in the direction of the arrow while pulling on the blade. Be careful when handling hot blades.

Quik-Lok® Blade Clamp Maintenance

•Periodically clean dust and debris from the Quik- Lok® Blade Clamp with dry compressed air.

•If the collar resists twisting, twist itr back and forth to shake debris loose.

•Periodically lubricate Quik-Lok® Blade Clamp with dry lubricant such as graphite.

Removing broken blades from the Quik-Lok® Blade Clamp

Unplug the tool before removing blades. Broken blades can be removed by the following methods.

•Point the tool downward, twist the collar, and shake the tool up and down (do not turn the tool on while your fingers are holding the blade clamp open). The shank of the broken blade should drop out of the clamp.

•If shaking the tool doesn't work:

In most cases, a corner of the broken blade will extend beyond the blade clamp. Simply twist the collar and pull the broken blade out of the clamp by this corner.

•If the broken stub doesn't extend far enough to be grabbed by its corner, use a thin blade with small teeth (such as a metal cutting blade) to hook the blade that is jammed in the clamp while twisting the collar and pull it out.

OPERATION

WARNING To reduce the risk of injury, wearsafetygogglesorglasseswithsideshields.

Adjustable Pivot Shoe

The shoe can be adjusted forward or backward to six positions to take advantage of the unused portion of the blade or for special jobs requiring low blade clearance.

Fig. 3

1/4 Turn

1.To a d j u s t t h e s h o e , p u l l t h e s h o e release lever down 1/4 turn and slide the shoe forward or backward to the desired position.

2.To lock the shoe in position, push the shoe release lever up.

3.After adjusting the shoe, slowly pull the trigger to be sure the blade always extends beyond the shoe and your work through- out the stroke.

DO NOT OPERATE SAWZALL WITHOUT SHOE. STRIKING THE SPINDLE AGAINST WORK MAY DAMAGE THE RECIPROCATING MECHANISM.