POWER TOOL USE AND CARE

POWER TOOL USE AND CARE

16. | Do not force the power tool. Use the |

| correct power tool for your applica- |

| tion. The correct power tool will do the |

| job better and safer at the rate for which |

| it was designed. |

17. | Do not use the power tool if the switch |

| does not turn it on and off.Any power tool |

| that cannot be controlled with the switch is |

| dangerous and must be repaired. |

18. | Disconnect the plug from the power |

25. | Use power tools only with specifically |

| designated battery packs. Use of any |

| other battery packs may create a risk of |

| injury and fire. |

26. | When battery pack is not in use, keep |

| it away from other metal objects like |

| paper clips, coins, keys, nails, screws, |

| or other small metal objects that can |

| make a connection from one terminal |

| to another. Shorting the battery terminals |

| together may cause burns or a fire. |

27. | Under abusive conditions, liquid may |

| be ejected from the battery, avoid |

3.Wear ear protectors with impact drills. Exposure to noise can cause hearing loss.

4.Hold power tools by insulated grip- ping surfaces when performing an operation where the cutting tool may contact hidden wiring or its own cord. Contact with a “live” wire will make ex- posed metal parts of the tool “live” and shock the operator.

Symbology

Volts Direct Current

Impacts per Minute

Under Load (IPM)

Underwriters

Laboratories, Inc.

source and/or the battery pack from |

the power tool before making any |

adjustments, changing accessories, |

or storing power tools. Such preven- |

tive safety measures reduce the risk of |

starting the tool accidentally. |

19. Store idle power tools out of the reach |

of children and do not allow persons |

unfamiliar with the power tools or |

these instructions to operate power |

tools. Power tools are dangerous in the |

hands of untrained users. |

20. Maintain power tools. Check for |

misalignment or binding of moving |

parts, breakage of parts and any |

other condition that may affect the |

power tool's operation. If damaged, |

have the power tool repaired before |

use. Many accidents are caused by |

poorly maintained power tools. |

21. Keep cutting tools sharp and clean. |

Properly maintained cutting tools with |

sharp cutting edges are less likely to |

bind and are easier to control. |

22. Use the power tool, accessories and |

tool bits etc., in accordance with |

these instructions and in the manner |

intended for the particular type of |

power tool, taking into account the |

working conditions and the work to |

be performed. Use of the power tool for |

operations different from those intended |

could result in a hazardous situation. |

BATTERY TOOL USE AND CARE

BATTERY TOOL USE AND CARE

23.Ensure the switch is in the off posi- tion before inserting battery pack. Inserting the battery pack into power tools that have the switch on invites accidents.

24.Recharge only with the charger speci- fied by the manufacturer. A charger that is suitable for one type of battery pack may create a risk of fire when used with another battery pack.

contact. If contact accidentally oc- |

curs, flush with water. If liquid con- |

tacts eyes, additionally seek medical |

help. Liquid ejected from the battery |

may cause irritation or burns. |

SERVICE

28.Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the power tool is maintained.

SPECIFIC SAFETY RULES

1.Maintain labels and nameplates. These carry important information. If unreadable or missing, contact a MILWAUKEE service facility for a free replacement.

2.WARNING! Some dust created by power sanding, sawing, grinding, drill- ing, and other construction activities contains chemicals known to cause cancer, birth defects or other reproduc- tive harm. Some examples of these chemicals are:

•lead from

•crystalline silica from bricks and cement and other masonry products, and

•arsenic and chromium from chemically- treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a well ven- tilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles.

Specifications

Catalog |

|

|

| Drive |

| Average |

| Volts |

| IPM | Torque | ||

No. | Type | DC | RPM | Shank | Output | |

Impact Driver | 14.4 | 1/4" Hex | 740 | |||

Impact Wrench | 14.4 | 3/8" Square | 1056 | |||

Impact Wrench | 14.4 | 1/2" Square | 1404 | |||

|

|

|

|

|

|

|

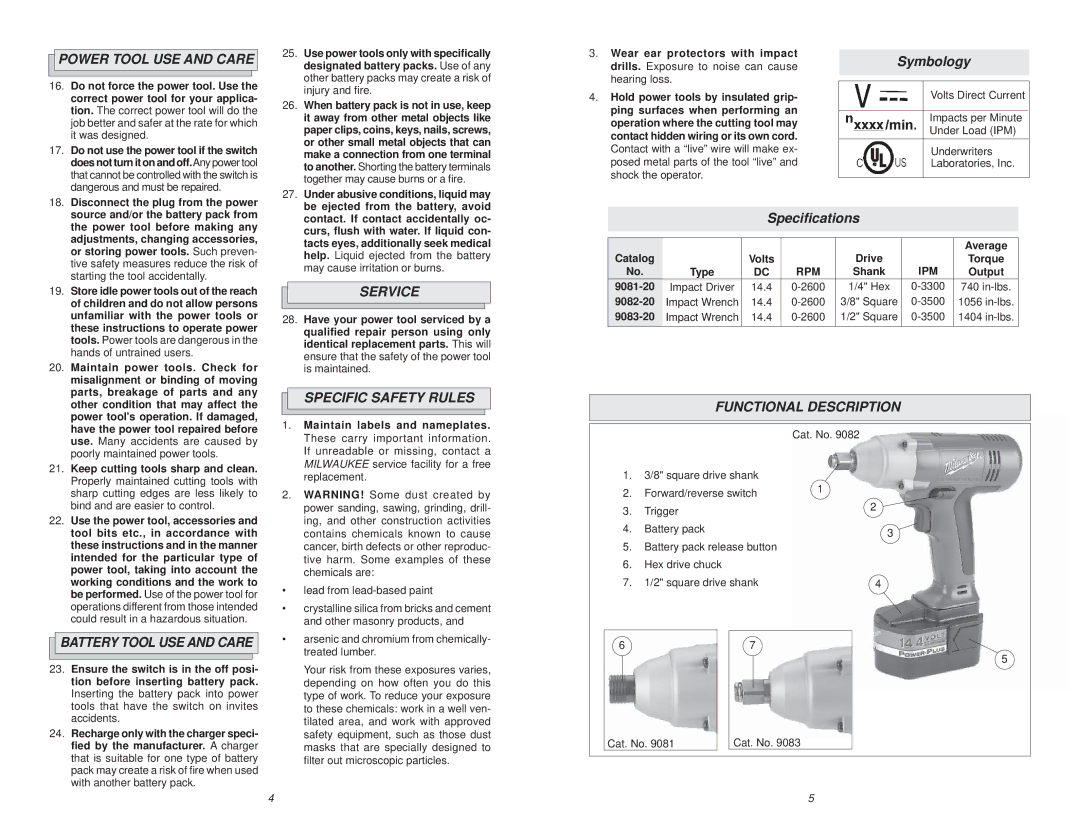

FUNCTIONAL DESCRIPTION

Cat. No. 9082

1.3/8" square drive shank

2. | Forward/reverse switch | 1 | |

2 | |||

3. | Trigger | ||

| |||

4. | Battery pack | 3 | |

|

|

5.Battery pack release button

6.Hex drive chuck

7. | 1/2" square drive shank | 4 |

6 | 7 |

|

5

Cat. No. 9081 | Cat. No. 9083 |

4 | 5 |