The torque speci![]() cations shown here are approximate values obtained with a fully charged battery pack.

cations shown here are approximate values obtained with a fully charged battery pack.

|

|

|

|

|

|

Small screws in softwood. | ||

Medium screws in softwood or small | ||

screws in hardwood. | ||

Large screws in softwoods. Medium | ||

screws in hardwood or large screws in | ||

|

| hardwood with pilot hole. |

![]() Because the settings shown in the table are only a guide, use a piece of scrap material to test the different clutch settings before driving screws into the workpiece.

Because the settings shown in the table are only a guide, use a piece of scrap material to test the different clutch settings before driving screws into the workpiece.

The speed selector is on top of the motor housing.

Allow the tool to come to a complete stop before

changing speeds. See “Applications” for recom- | ||

mended speeds under various | ||

conditions. | speed, push the | |

1. | For | |

2. | speed selector to display “1”. | |

For | speed, push the | |

| speed selector to display “2”. | |

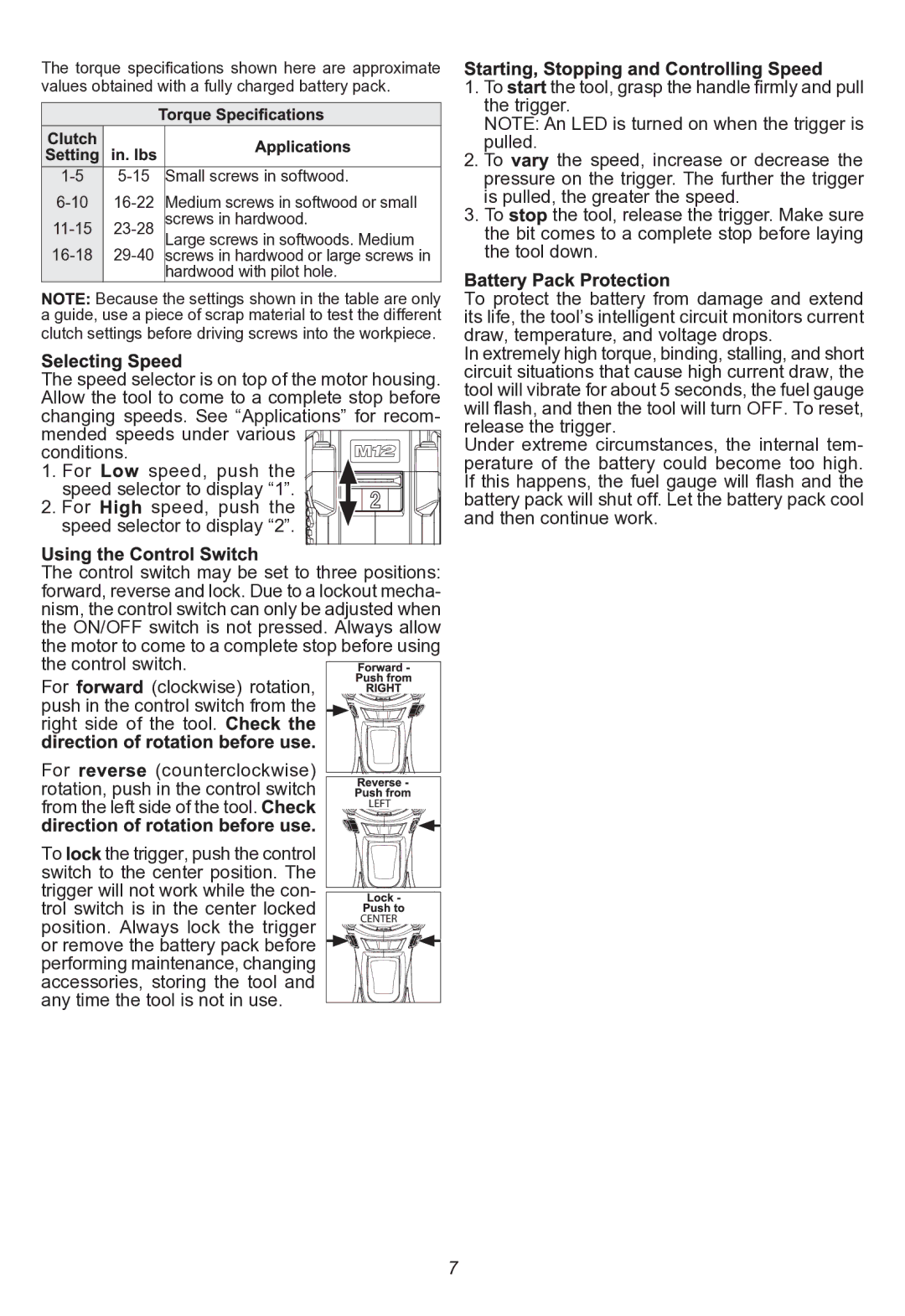

The control switch may be set to three positions: | ||

forward, reverse and lock. Due to a lockout mecha-

nism, the control switch can only be adjusted when

the ON/OFF switch is not pressed. Always allow

the motor to come to a complete stop before using | |||

the control switch. |

| ||

For | (clockwise) rotation, |

| |

push in the control switch from the |

| ||

right side of the tool. |

| ||

For | (counterclockwise) |

| |

rotation, push in the control switch |

| ||

from the left side of the tool. | LEFT | ||

| |||

To | the trigger, push the control |

| |

switch to the center position. The |

| ||

trigger will not work while the con- |

| ||

trol switch is in the center locked | CENTER | ||

position. Always lock the trigger | |||

| |||

or remove the battery pack before |

| ||

performing maintenance, changing |

| ||

accessories, storing the tool and |

| ||

any time the tool is not in use. |

| ||

1.To ![]() the tool, grasp the handle

the tool, grasp the handle ![]() rmly and pull the trigger.

rmly and pull the trigger.

NOTE: An LED is turned on when the trigger is pulled.

2.To the speed, increase or decrease the pressure on the trigger. The further the trigger is pulled, the greater the speed.

3.To the tool, release the trigger. Make sure the bit comes to a complete stop before laying the tool down.

To protect the battery from damage and extend its life, the tool’s intelligent circuit monitors current draw, temperature, and voltage drops.

In extremely high torque, binding, stalling, and short circuit situations that cause high current draw, the tool will vibrate for about 5 seconds, the fuel gauge will ![]() ash, and then the tool will turn OFF. To reset, release the trigger.

ash, and then the tool will turn OFF. To reset, release the trigger.

Under extreme circumstances, the internal tem- perature of the battery could become too high. If this happens, the fuel gauge will ![]() ash and the battery pack will shut off. Let the battery pack cool and then continue work.

ash and the battery pack will shut off. Let the battery pack cool and then continue work.

7