Stage 2: Building the Upper Wing

The upper wing is built in two separate sections that will be joined later at the air- craft’s center line. Refer to Figures 2/1 through 2/15 for the number and location of the parts. Ribs are numbered out from the centerline. The following procedures will need to be repeated for the right and left upper wings.

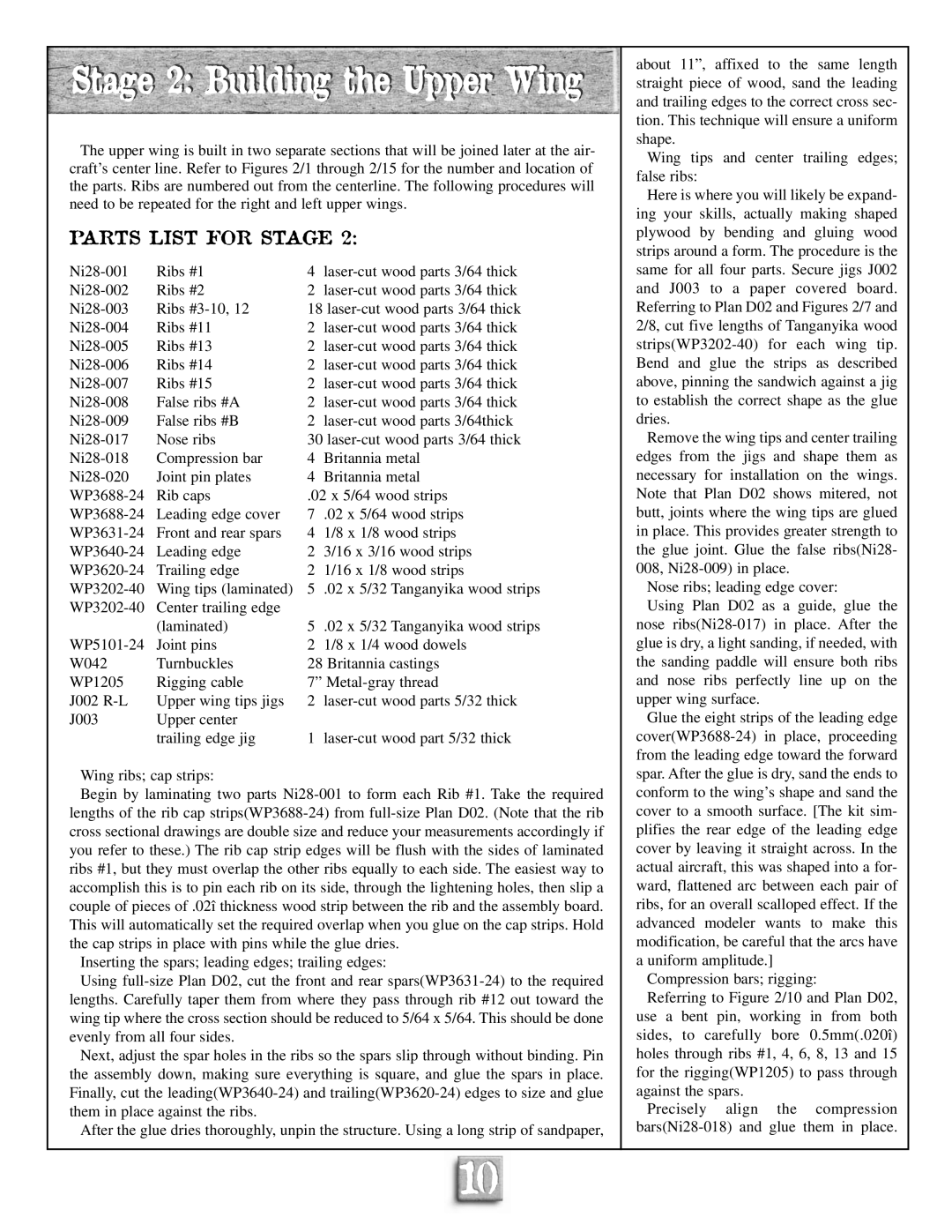

PARTS LIST FOR STAGE 2:

Ribs #1 | 4 | ||

Ribs #2 | 2 | ||

Ribs | 18 | ||

Ribs #11 | 2 | ||

Ribs #13 | 2 | ||

Ribs #14 | 2 | ||

Ribs #15 | 2 | ||

False ribs #A | 2 | ||

False ribs #B | 2 | ||

Nose ribs | 30 | ||

Compression bar | 4 | Britannia metal | |

Joint pin plates | 4 | Britannia metal | |

Rib caps | .02 x 5/64 wood strips | ||

Leading edge cover | 7 | .02 x 5/64 wood strips | |

Front and rear spars | 4 | 1/8 x 1/8 wood strips | |

Leading edge | 2 | 3/16 x 3/16 wood strips | |

Trailing edge | 2 | 1/16 x 1/8 wood strips | |

Wing tips (laminated) | 5 | .02 x 5/32 Tanganyika wood strips | |

|

| ||

| (laminated) | 5 | .02 x 5/32 Tanganyika wood strips |

Joint pins | 2 | 1/8 x 1/4 wood dowels | |

W042 | Turnbuckles | 28 Britannia castings | |

WP1205 | Rigging cable | 7” | |

J002 | Upper wing tips jigs | 2 | |

J003 | Upper center |

|

|

| trailing edge jig | 1 | |

Wing ribs; cap strips:

Begin by laminating two parts

Inserting the spars; leading edges; trailing edges:

Using

Next, adjust the spar holes in the ribs so the spars slip through without binding. Pin the assembly down, making sure everything is square, and glue the spars in place. Finally, cut the

After the glue dries thoroughly, unpin the structure. Using a long strip of sandpaper,

about 11”, affixed to the same length straight piece of wood, sand the leading and trailing edges to the correct cross sec- tion. This technique will ensure a uniform shape.

Wing tips and center trailing edges; false ribs:

Here is where you will likely be expand- ing your skills, actually making shaped plywood by bending and gluing wood strips around a form. The procedure is the same for all four parts. Secure jigs J002 and J003 to a paper covered board. Referring to Plan D02 and Figures 2/7 and 2/8, cut five lengths of Tanganyika wood

Remove the wing tips and center trailing edges from the jigs and shape them as necessary for installation on the wings. Note that Plan D02 shows mitered, not butt, joints where the wing tips are glued in place. This provides greater strength to the glue joint. Glue the false ribs(Ni28- 008,

Nose ribs; leading edge cover:

Using Plan D02 as a guide, glue the nose

Glue the eight strips of the leading edge

Compression bars; rigging:

Referring to Figure 2/10 and Plan D02, use a bent pin, working in from both sides, to carefully bore 0.5mm(.020î) holes through ribs #1, 4, 6, 8, 13 and 15 for the rigging(WP1205) to pass through against the spars.

Precisely align the compression

10