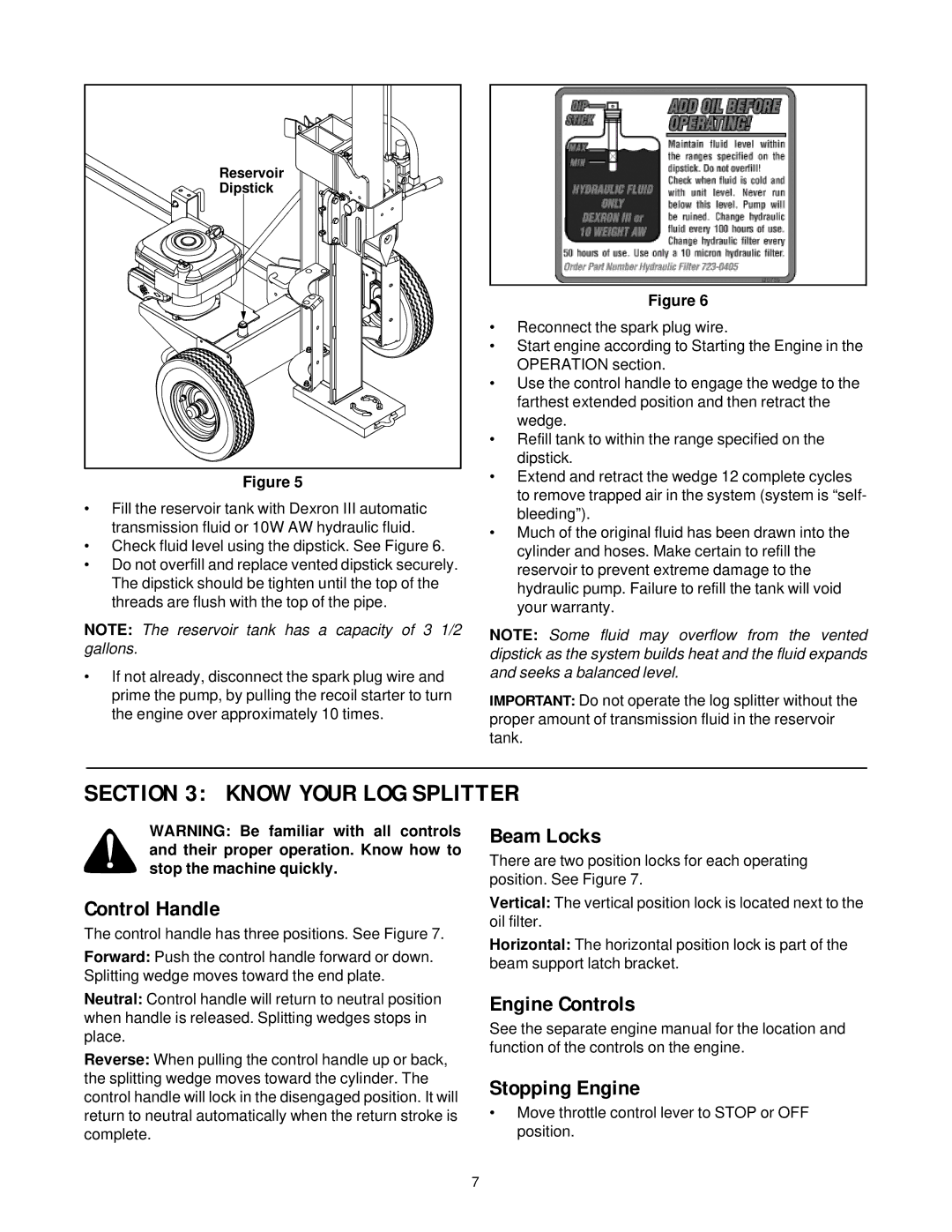

Reservoir |

Dipstick |

Figure 5

•Fill the reservoir tank with Dexron III automatic transmission fluid or 10W AW hydraulic fluid.

•Check fluid level using the dipstick. See Figure 6.

•Do not overfill and replace vented dipstick securely. The dipstick should be tighten until the top of the threads are flush with the top of the pipe.

NOTE: The reservoir tank has a capacity of 3 1/2 gallons.

•If not already, disconnect the spark plug wire and prime the pump, by pulling the recoil starter to turn the engine over approximately 10 times.

Figure 6

•Reconnect the spark plug wire.

•Start engine according to Starting the Engine in the OPERATION section.

•Use the control handle to engage the wedge to the farthest extended position and then retract the wedge.

•Refill tank to within the range specified on the dipstick.

•Extend and retract the wedge 12 complete cycles to remove trapped air in the system (system is “self- bleeding”).

•Much of the original fluid has been drawn into the cylinder and hoses. Make certain to refill the reservoir to prevent extreme damage to the hydraulic pump. Failure to refill the tank will void your warranty.

NOTE: Some fluid may overflow from the vented dipstick as the system builds heat and the fluid expands and seeks a balanced level.

IMPORTANT: Do not operate the log splitter without the proper amount of transmission fluid in the reservoir tank.

SECTION 3: KNOW YOUR LOG SPLITTER

WARNING: Be familiar with all controls and their proper operation. Know how to stop the machine quickly.

Control Handle

The control handle has three positions. See Figure 7.

Forward: Push the control handle forward or down. Splitting wedge moves toward the end plate.

Neutral: Control handle will return to neutral position when handle is released. Splitting wedges stops in place.

Reverse: When pulling the control handle up or back, the splitting wedge moves toward the cylinder. The control handle will lock in the disengaged position. It will return to neutral automatically when the return stroke is complete.

Beam Locks

There are two position locks for each operating position. See Figure 7.

Vertical: The vertical position lock is located next to the oil filter.

Horizontal: The horizontal position lock is part of the beam support latch bracket.

Engine Controls

See the separate engine manual for the location and function of the controls on the engine.

Stopping Engine

•Move throttle control lever to STOP or OFF position.

7