Always:

•Use clean fluid and check fluid level regularly.

•Use Dexron III Automatic Transmission Fluid or 10W AW hydraulic fluid.

•Use a filter (clean or replace regularly)

•Use a breather cap on fluid reservoir.

•Make certain pump is mounted and aligned properly.

•Use a flexible “spider” type coupling between engine and pump drive shafts.

•Keep hoses clear and unblocked.

•Bleed air out of hoses before operating.

•Flush and clean hydraulic system before starting after any malfunction or servicing.

•Use “pipe dope” on all hydraulic fittings.

•Allow time for

•Prime the pump before initial

•Split wood with the grain (lengthwise) only.

Never:

•Use when fluid is below 20° F or above 150° F.

•Use a solid engine /pump coupling.

•Operate through relief valve for more than several seconds.

•Attempt to adjust unloading or relief valve settings without pressure gauges.

•Operate with air in hydraulic system.

•Use teflon tape on hydraulic fittings.

•Attempt to cut wood across the grain.

Using The Log Splitter

•Place the log splitter on level, dry, and solid ground.

•Place the beam in either the horizontal or vertical position and lock in place with the appropriate locking rod.

•Block the front and back of both wheels.

•Place the log against the end plate and only split wood in the direction of the grain.

•When necessary to stabilize the log, place your hand only on sides of log. NEVER place hand on the end between the log and splitting wedge.

•Only one adult should stabilize the log and operate the control handle, so the operator has full control over stabilizing the log and movement of the splitting wedge.

Control Handle Positions

•Move control handle FORWARD or DOWN to split wood.

•Release the control handle to stop the wedge movement.

•Move control handle BACK or UP to return the wedge.

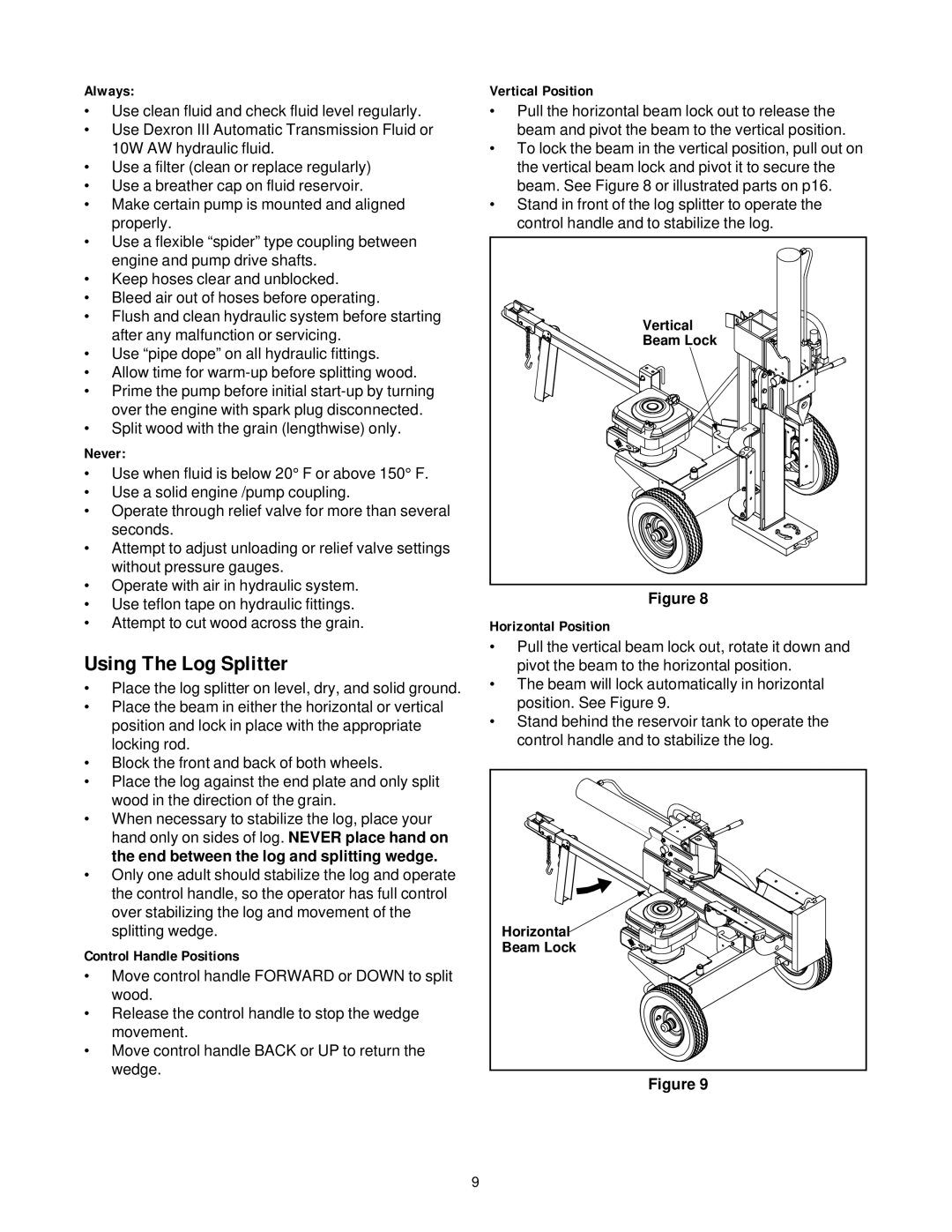

Vertical Position

•Pull the horizontal beam lock out to release the beam and pivot the beam to the vertical position.

•To lock the beam in the vertical position, pull out on the vertical beam lock and pivot it to secure the beam. See Figure 8 or illustrated parts on p16.

•Stand in front of the log splitter to operate the control handle and to stabilize the log.

Vertical |

Beam Lock |

Figure 8

Horizontal Position

•Pull the vertical beam lock out, rotate it down and pivot the beam to the horizontal position.

•The beam will lock automatically in horizontal position. See Figure 9.

•Stand behind the reservoir tank to operate the control handle and to stabilize the log.

Horizontal |

Beam Lock |

Figure 9

9