SECTION 9: MAINTENANCE

WARNING: Disconnect the spark plug wire and ground against the engine before performing any repairs or maintenance.

AUGERS

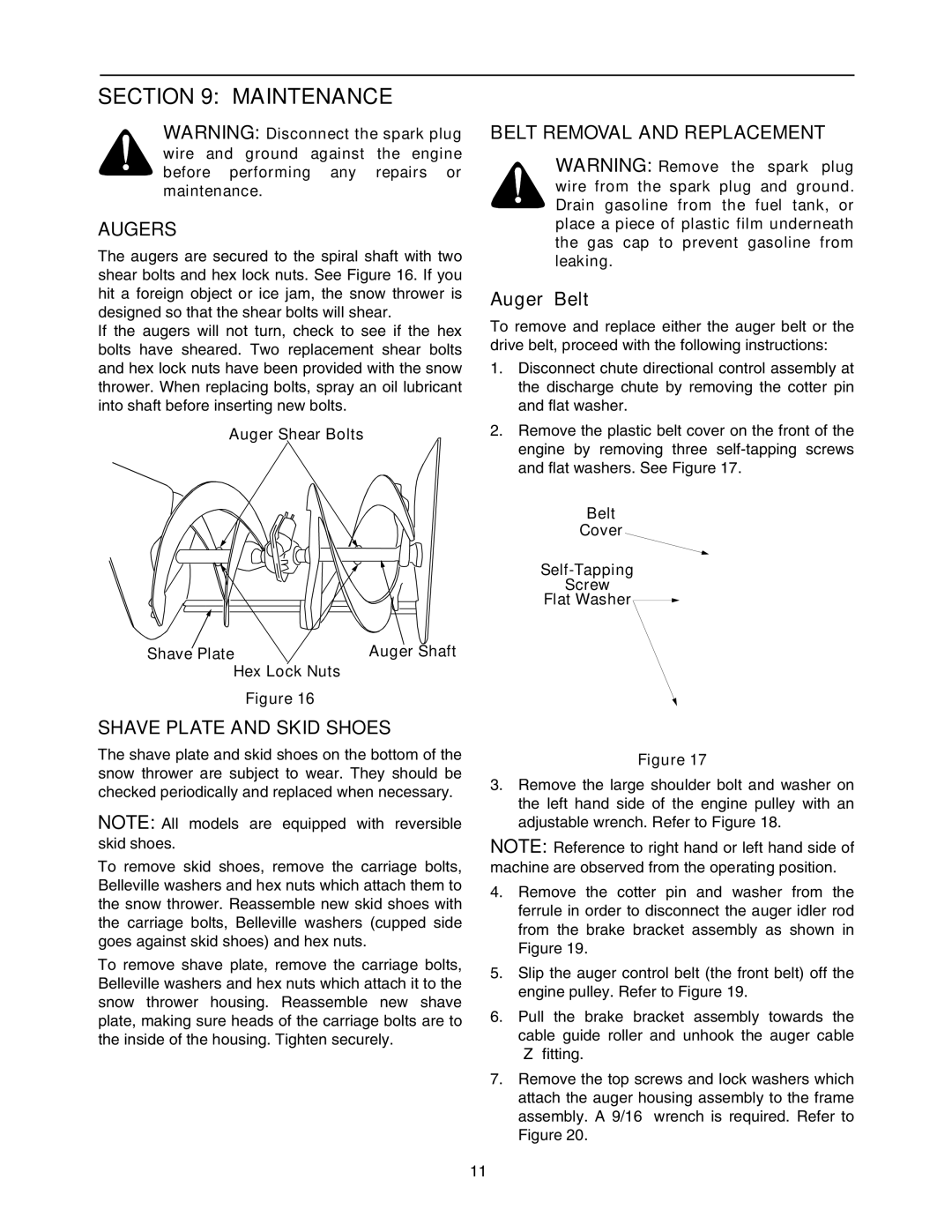

The augers are secured to the spiral shaft with two shear bolts and hex lock nuts. See Figure 16. If you hit a foreign object or ice jam, the snow thrower is designed so that the shear bolts will shear.

If the augers will not turn, check to see if the hex bolts have sheared. Two replacement shear bolts and hex lock nuts have been provided with the snow thrower. When replacing bolts, spray an oil lubricant into shaft before inserting new bolts.

Auger Shear Bolts

Shave Plate | Auger Shaft |

Hex Lock Nuts |

|

Figure 16

SHAVE PLATE AND SKID SHOES

The shave plate and skid shoes on the bottom of the snow thrower are subject to wear. They should be checked periodically and replaced when necessary.

NOTE: All models are equipped with reversible skid shoes.

To remove skid shoes, remove the carriage bolts, Belleville washers and hex nuts which attach them to the snow thrower. Reassemble new skid shoes with the carriage bolts, Belleville washers (cupped side goes against skid shoes) and hex nuts.

To remove shave plate, remove the carriage bolts, Belleville washers and hex nuts which attach it to the snow thrower housing. Reassemble new shave plate, making sure heads of the carriage bolts are to the inside of the housing. Tighten securely.

BELT REMOVAL AND REPLACEMENT

WARNING: Remove the spark plug wire from the spark plug and ground. Drain gasoline from the fuel tank, or place a piece of plastic film underneath the gas cap to prevent gasoline from leaking.

Auger Belt

To remove and replace either the auger belt or the drive belt, proceed with the following instructions:

1.Disconnect chute directional control assembly at the discharge chute by removing the cotter pin and flat washer.

2.Remove the plastic belt cover on the front of the engine by removing three

Belt

Cover

Self-Tapping

Screw

Flat Washer

Figure 17

3.Remove the large shoulder bolt and washer on the left hand side of the engine pulley with an adjustable wrench. Refer to Figure 18.

NOTE: Reference to right hand or left hand side of machine are observed from the operating position.

4.Remove the cotter pin and washer from the ferrule in order to disconnect the auger idler rod from the brake bracket assembly as shown in Figure 19.

5.Slip the auger control belt (the front belt) off the engine pulley. Refer to Figure 19.

6.Pull the brake bracket assembly towards the cable guide roller and unhook the auger cable “Z” fitting.

7.Remove the top screws and lock washers which attach the auger housing assembly to the frame assembly. A 9/16” wrench is required. Refer to Figure 20.

11