BA-SERIES

Page

Page

BA-SERIES TROWEL- Table of Contents

Order via Fax Dealers Only

BA-SERIES TROWEL- Parts Ordering Procedures

Best Deal! Order via Internet Dealers Only

BA-SERIES TROWEL- Training Checklist

Daily PRE-OPERATION Checklist

BA-SERIES TROWEL- Daily PRE-OPERATION Checklist

Foryour Safety Andthe Safety of Others

BA-SERIES TROWEL- Safety Message Alert Symbols

Over Speed Conditions Sight and Hearing hazard

BA-SERIES TROWEL- Safety Message Alert Symbols

BA-SERIES TROWEL- Rules for Safe Operation

Safety

Emergencies

Maintenance Safety

BA-SERIES TROWEL- Rules for Safe Operation

Machine Safety Decals

BA-SERIES TROWEL- Operation and Safety Decals

SideView

BA-SERIES TROWEL- Specifications Trowel

Specifications Engines & Electric Motor

BA-SERIES TROWEL- Specifications Engines

BA-SERIES TROWEL- General Information

BA-Series Walk-Behind Trowels

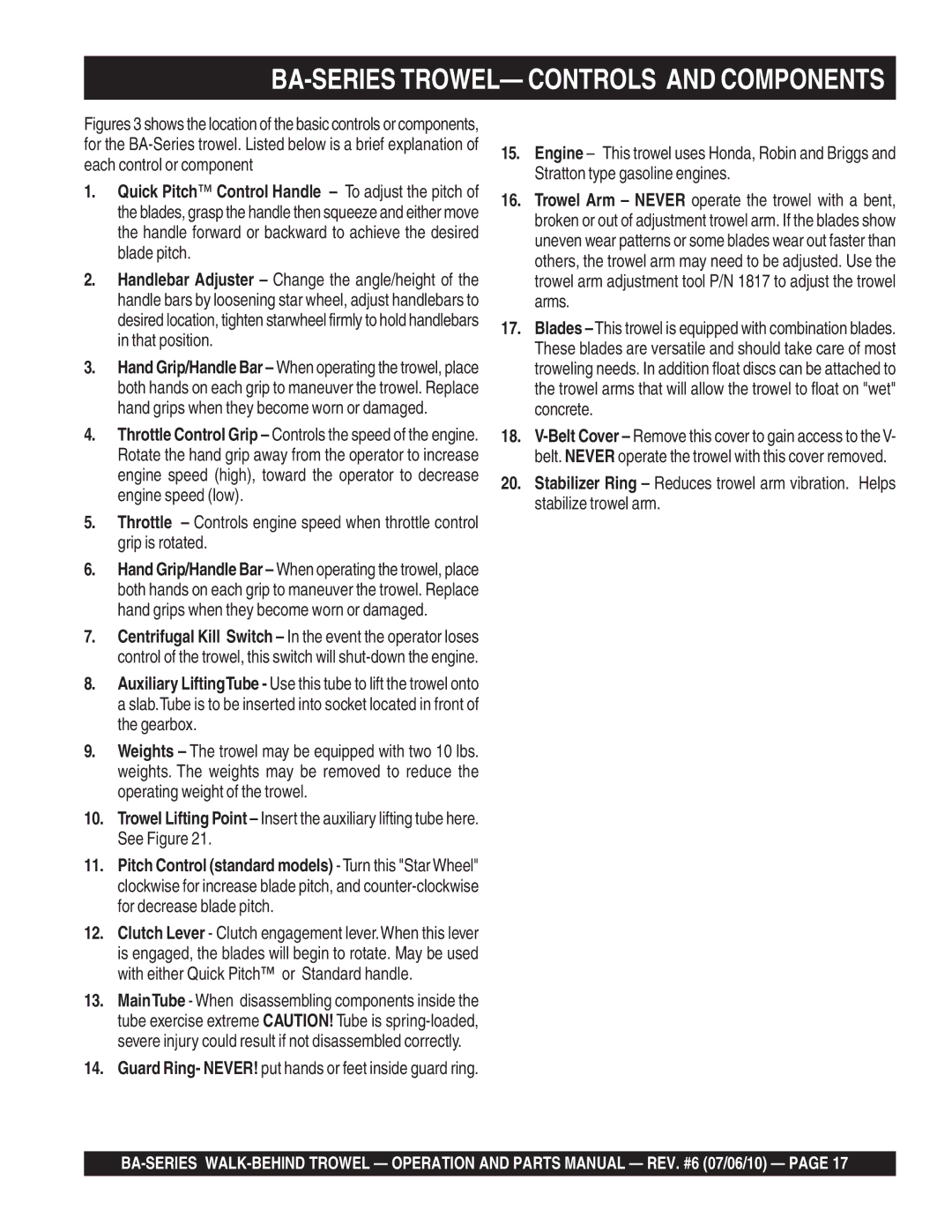

BA-SERIES TROWEL- Controls and Components

BA-SERIES TROWEL- Controls and Components

BA-SERIES TROWEL- Basic Engine

HandleTube Installation All Models

BA-SERIES Trowel Assembly and Installation

Assembly and Installation

Safety KillWire

BA-SERIES Trowel Assembly and Installation

Blade Pitch Cable

BA-SERIES Trowel Assembly and Installation

Engine Oil Check

BA-SERIES TROWEL- PRE-INSPECTION

Before Starting

BA-SERIES TROWEL- PRE-INSPECTION

Starting the Engine Honda engine

Lifting theTrowel Onto a Slab Auxiliary Lifting Tube

Lifting Bale Option

BA-SERIESTROWEL Initial START-UP

Centrifugal Kill Switch

PitchingThe Blades Quick Pitch Handle

BA-SERIES Trowel Operation

BA-SERIES Trowel Operation

Combo Blades

BA-SERIES Trowel Options

Clip-On Float Blades Optional

Grinding Attachments

Trowel Arm Adjustment Tool

Daily 8-10 Hours

Trowel Arm Adjustment Procedure

Weekly 50-60 Hours

Monthly 200-300 Hours

Trowel Arm Removal

BA-SERIES Trowel Maintenance

Spider Removal

Trowel Arm Flatness Test

Bronze Bushings Trowel Blade Removal

Re-Assembly

Trowel Arm Adjustment

Changing a Blade

Testing

Hand Clutch Adjustment

Troubleshooting

BA-SERIES Trowel Troubleshooting Trowel

Worn bearings in gearbox?

BA-SERIES Trowel Troubleshooting Trowel

Troubleshooting Engine

BA-SERIES Trowel Troubleshooting Engine

Xxxxx only Not Used on

BA-SERIESTROWEL Explanation of Codes in Remarks Column

To 3 Units

BA-SERIES Trowel Suggested Spare Parts

Nameplates and Decals Quick Pitch Handle

BA-SERIES Trowel Nameplate and Decals

Decal Power Trowel

Decal PRE-LOAD Indicator

Nameplate and Decals

Decal QUICK-PITCH Handle

Standard Handle Assy Detail B Detail a See

BA-SERIESTROWEL Standard Handle Assy

BA-SERIESTROWEL Standard Handle Assy

QUICK-PITCH T-HANDLE Detail B Detail a See

BA-SERIESTROWEL QUICK-PITCH Handle Assy

BLOCK, QP Adjustment

CONNECTOR, QP Control ARM

DECAL, Preload Trim Indicator

DECAL, Latch Warning

Quick Pitch Handle Detail B Detail a See

BA-SERIESTROWEL Quick Pitch Handle Assy

HOUSING, Throttle Cable

SCREW, QP Trim Adjustment

DECAL, Arrow

NUT, QP Trim Ctrl ADJ

BA-SERIESTROWEL -THRUST Bearing KIT Assy

Thrust Bearing KIT Assembly

Flange Bearing

Wear Ring

Thrust Collar W/BUSHING

Bushing

Blade Spider Assy

BA-SERIESTROWEL 4-BLADE Spider Assy

Wear Plate

Assy

Bearing Insert

INT. SHKP. Washer 3/8

OIL for Operation

BA-SERIESTROWEL Gearbox and Engine Mounts Assy

BA-SERIESTROWEL Gearbox and Engine Mounts Assy

BA-SERIESTROWEL Gearbox and Engine Mounts Assy

Front Engine Mount Robin

Front Engine Mount Honda

Front Engine Mount Briggs

Rear Engine Mount Honda 8HP

BA-SERIESTROWEL ENGINES, HONDA, ROBIN, Briggs & Stratton

Engine 8HP Honda

Hand Clutch Assy

BA-SERIESTROWEL Hand Clutch Assy

Part Name QTY

BA-SERIESTROWEL Hand Clutch Assy

Guard Ring Assy

BA-SERIESTROWEL Guard Ring Assy

Guard Ring Assy

Detail a

BA-SERIESTROWEL Stabilizer Ring Assy

WASHER, LOCK, 5/16 MED

Blades & Adjustment Fixture Assy

BA-SERIESTROWEL Blades & Adjustment Fixture Assy

LUBRA-CAP

BA-SERIESTROWEL Blades & Adjustment Fixture Assy

Lifting Bale ASSY. Option

BA-SERIESTROWEL Lifting Bale ASSY. Option

Spacer Robin Engine

AIR Cleaner Assy

Honda GX240K1QA2 Engine AIR Cleaner Assy

GROMMET, AIR Cleaner

COVER, AIR Cleaner

COLLAR, AIR Cleaner

Collar B, AIR Cleaner

Camshaft Assy

Honda GX240K1QA2 Engine Camshaft Assy

ROD Push

SPRING, Weight Return

ARM Valve Rocker

Lifter Valve

Carburetor Assy

Honda GX240K1QA2 Engine Carburetor Assy

Gasket SET

PLATE, Lever Setting

Valve SET, Float

Float SET

Control Assy

Honda GX240K1QA2 Engine Control Assy

ROD, Governor

ARM, Governor

SPRING, Governor

SPRING, Throttle Return

Crankcase Cover Assy

Honda GX240K1QA2 Engine Crankcase Cover Assy

HOLDER, Governor Weight

WEIGHT, Governor

PIN, Governor Weight

GASKET, Case Cover

Crankshaft Assy

Honda GX240K1QA2 Engine Crankshaft Assy

90745ZE2600 KEY 6.3 X 6.3 X 961006206000

WEIGHT, Balancer

Cylinder Barrel Assy

Honda GX240K1QA2 Engine Cylinder Barrel Assy

BOLT, Drain Plug

SHAFT, Governor ARM

OIL Seal

WASHER, Drain Plug 12MM

Cylinder Head Assy

Honda GX240K1QA2 Engine Cylinder Head Assy

GUIDE, EX. VALVE, OS, Optional

GUIDE, VALVE, OS, Optional

CLIP, Valve Guide

GASKET, Cylinder Head

FAN Cover Assy

Honda GX240K1QA2ENGINE FAN Cover Assy

CLIP, Wire Harness

Switch ASSY., Engine Stop

CLIP, Tube

Shroud

Flywheel Assy

Honda GX240K1QA2 Engine Flywheel Assy

Flywheel Comp

FAN, Cooling

NUT, Special 16MM

KEY, Special Woodruff

Fuel Tank Assy

Honda GX240K1QA2ENGINE Fueltank Assy

JOINT, Fuel Tank

Rubber Supporter 107MM

Tank COMP., Fuel *NH1*, Black

GASKET, Fuel Filler CAP

Ignition Coil Assy

Honda GX240K1QA2 Engine Ignition Coil Assy

WIRE, Stop Switch 370MM

GROMMET, Wire

Coil ASSY., Ignition

CAP ASSY., Noise Suppressor

Muffler Assy

Honda GX240K1QA2 Engine Muffler Assy

Protector COMP., Muffler

Muffler Comp

PROTECTOR, EX. Pipe

PIPE, EX

Piston Assy

Honda GX240K1QA2 Engine Piston Assy

Ring SET, PISTON, STD

BOLT, Connecting ROD

Ring SET, PISTON, 0.75, Optional

PISTON, Standard

Recoil Starter Assy

Honda GX240K1QA2 Engine Recoil Starter Assy

Honda GX240K1QA2 Engine Recoil Starter Assy

Labels

Honda GX240K1QA2 Engine Labels

LABEL, Caution

EMBLEM, Internal

MARK, CHOKE, External

MARK, OIL ALERT, E

Crankcase Assy

Robin EH25-2 Engine Crankcase Assy

Valve Guide

Includes Items W

Ball Bearing 6206C3

Ball Bearing 6202C3

Robin EH25-2 Engine Crankshaft Assy

NUT

Connecting ROD Bolt

Spring Washer

Woodruff KEY

Intake and Exhaust Assy

Robin EH25-2 Engine Intake and Exhaust Assy

Spring PIN

Release Lever

Snap Ring

Tappet

Governor Assy

Robin EH25-2 Engine Governor Assy

Governor Lever

Wire Bracket

Governor Shaft

Governor ROD CP

Cooling and Starting Assy

Robin EH25-2 Engine Cooling and Starting Assy

LABEL, Trade Mark

Blower Housing CP

LABEL, Recoil OHV

Head Cover

Robin EH25-2 Engine Fueltank Assy

Fuel Tank CAP CP

Fuel Tank CP

Fuel Filter CP

Filter

Robin EH25-2 Engine Carburetor Assy

Adjust Screw

Adjuster

Includes Items W/%

Throttle Valve

Flywheel and Ignition Assy

Robin EH25-2 Engine Flywheel and Ignition Assy

Flywheel CP

Switch Assy

Ignition Coil CP

Clamp

OIL Sensor Assy

Robin EH25-2 Engine OIL Sensor Assy

700 KS31102801

Terms and Conditions of Sale Parts

Page

HERE’S HOW to GET Help