Model MRH800GS

Proposition 65WARNING

Page

Table of Contents

Best Deal! Order via Internet Dealers Only

Parts Ordering Procedures

Order via Fax Dealers Only

MRH800GS Safety Message Alert Symbols

MRH800GS Safety Message Alert Symbols

MRH800GS Rules for Safe Operation

General Safety

MRH800GS Rules for Safe Operation

MRH800GS Operation and Safety Decals

MRH800GS Operation and Safety Decals

MRH800GS Roller Specifications

MRH800GS Engine Specifications

MRH800GS -VIBRATION Roller Dimensions

MRH800GS Features

MRH800GS Vibration Roller Components

MRH800GS -VIBRATION Roller Components

MRH800GS -VIBRATION Roller Components

MRH800GS Handle BAR/LEVER Components

Handle BAR/LEVER Components

MRH800GS Handle BAR/LEVER Components

Initial Servicing

MRH800GS Engine Components

Page

Checking The Hydraulic System

MRH800GS Inspection

Before Starting

Engine Oil Check

Checking Levers and Horn

Checking The Vibrator Oil Level

Vibrator Oil Level Plug

Checking Water Tank

Starting the Engine

MRH800GS Operation

Electric Start

Starter Grip

Recoil Start

Watering

Traveling

Parking

Off Position Vibration Lever

Lifting

Safety Features

Stopping

Unloading

Daily Service

Inspection and Maintenance Service Tables

MRH800GS Maitenance

Spark Plug

Roller Inspection and Adjustment

Air Filter

MRH800GS Maintenance

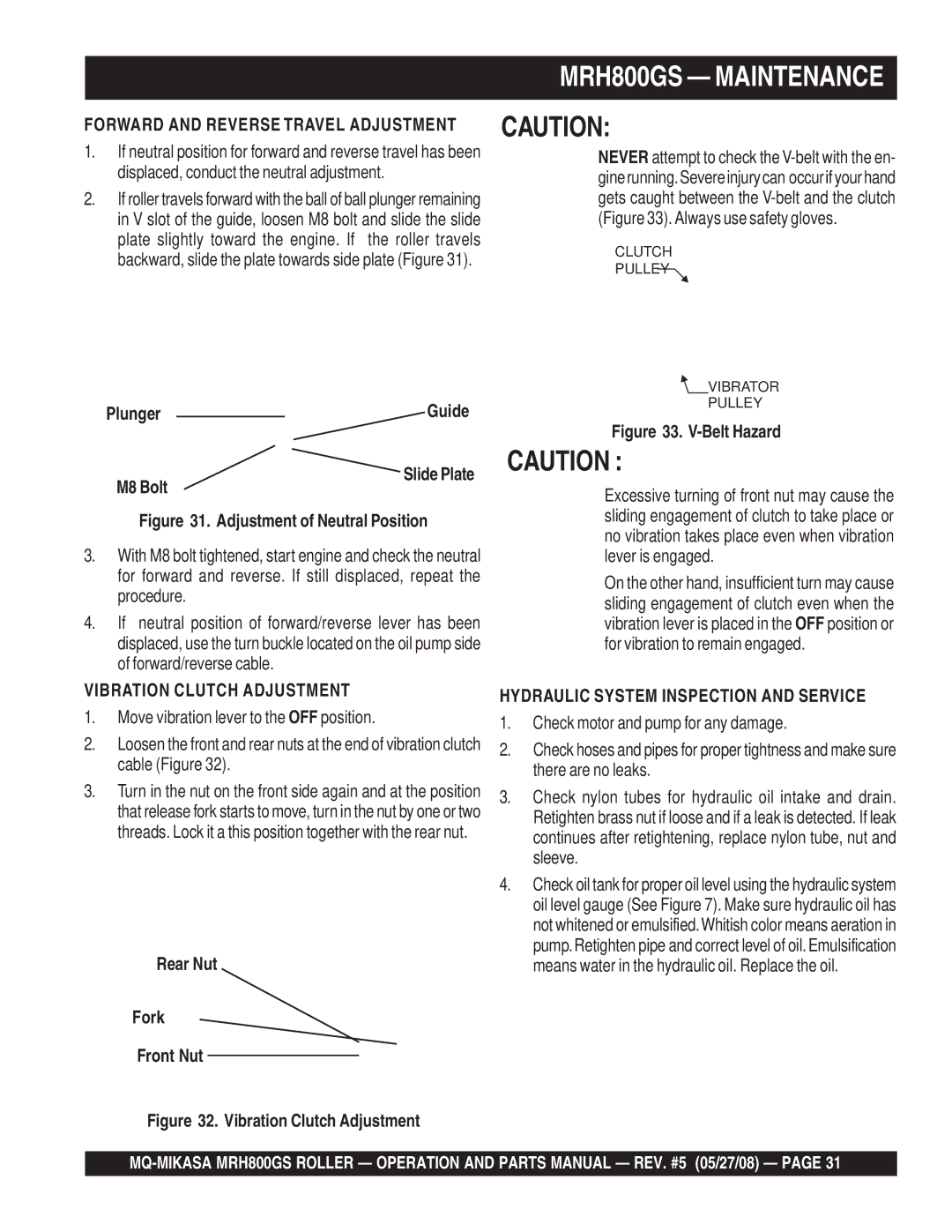

Vibration Clutch Adjustment

Forward and Reverse Travel Adjustment

Hydraulic System Inspection and Service

MRH-800GS Lubrication Chart

Vibrator Oil Maintenance

Handle Bar Maintenance Vibrator Oil

Page

MRH800GS Rollertroubleshooting

Engine Troubleshooting

MRH800GS -TROUBLESHOOTING

Air cleaner not clean?

Remarks Column

NO. Column

Part NO. Column

QTY. Column

Qty Description

Suggested Spare Parts

Decal Placement

MRH800GSVIBRATION Roller Decal Placement

DECAL, Mikasa Mobile DTE

Part Name

Axle Assy

MRH800GSVIBRATION Roller Axle Assy

Bearing 6308DU

Drum

Gear Plate

Drum Bracket R

Base Assy

MRH800GSVIBRATION Roller Base Assy

WASHER, Lock M10

Safety Guard

Assy

Base YANMAR-L100

Front Guard Assy

MRH800GSVIBRATION Roller Front Guard Assy

Bumper

Flat WASHER, M10

Lock WASHER, M10

Front Guard

Side Cover Assy

MRH800GSVIBRATION Roller Side Cover Assy

Rivet

SUPPORT, Cover

ROD Holder

Rubber Hinge

Water Tank Assy

MRH800GSVIBRATION Roller -WATERTANK Assy

Nylon NUT M10 SUS

Water Tank

CAP, Water Tank /MR

Washer 10.5X21X2 SUS

Hydraulic System Assy

MRH800GSVIBRATION Roller Hydraulic System Assy

Spiral Tube 11D-400L

Filter Head

OIL Element

Spiral Tube 11D-350L

MRH800GSVIBRATION Roller Hydraulic System Assy

WASHER, Flat M10 in SYSTEM8

HOLDER, Upper

HOLDER, Lower

COVER, Pipe

Hydraulic OIL Tank Assy

MRH800GSVIBRATION Roller Hydraulic Oiltank Assy

Level GAUGE/L =60

OIL TANK, Green

OIL Tank , Orange

Packing 1/4 CU

Engine Honda GX390 Assy

MRH800GSVIBRATION Roller Engine Assy

Bearing 6004DDU

SWITCH, Horn Button Assy

Wire Clamp

Tightener Pulley

Engine Honda GX390 ASSY.

MRH800GSVIBRATION Roller Engine ASSY.

Engine GX390K1SM32

Wire Harness

Switch CP, S-1B W/CORD

Clamp TC-150

Electric Device Honda GX390 Assy

MRH800GS Electric Device

MICRO-SWITCH ,700

ROD, Battery

HOLDER, Battery -6,7

Battery Cord

Clutch Vibration Assy

MRH800GSVIBRATION Roller Clutch Vibration Assy

Bearing

LOCK, Wire

Counter Pulley 130D-3V1

Counter Bracket

Vibrator Assy

MRH800GSVIBRATION Roller -VIBRATOR Assy

Gear

Vibrating Case

Bearing 6308C4

Gear Spacer

Upper Control ARM Assy

MRH800GSVIBRATION Roller Upper Control ARM Assy

MRH800GSVIBRATION Roller Upper Control ARM Assy

Upper Control ARM ASSY.

MRH800GSVIBRATION Roller Upper Control ARM ASSY.CONT

Conical Spring Washer M12

GUIDE, Wire E/G

Throttle Wire

KEY

Lower Control ARM Assy

MRH800GSVIBRATION Roller Lower Control ARM Assy

MRH800GSVIBRATION Roller Lower Control ARM Assy

Cylinder Head Assy

Honda GX-390K1SM32 Cylinder Head Assy

PACKING, Head Cover

CLIP, Valve Guide

GASKET, Cylinder Head

Cover COMP., Head

Cylinder Barrel Assy

Honda GX-390K1SM32 Cylinder Barrel Assy

PLUG, Sealing

Switch ASSY, OIL Level

SHAFT, Governor ARM

BOLT, Drain Plug

Crankcase Cover Assy

Honda GX-390K1SM32 Crankcase Cover Assy

BEARING, Radial

WEIGHT, Governor

SLIDER, Governor

Plain Washer 6MM

Crankshaft Assy

Honda GX-390K1SM32 Crankshaft Assy

WASHER, Lock 8MM

WEIGHT, Balancer

Piston Assy

Honda GX-390K1SM32 Piston Assy

CLIP,PISTON PIN 20MM

Ring SET, Piston

Piston STD

PIN Piston

Camshaft Assy

Honda GX-390K1SM32 Camshaft Assy

ARM, Valve Rocker

SPRING, Weight Return

NUT, Pibot Adjusting

ROD, Push

Recoil Starter Assy

Honda GX-390K1SM32 Recoil Starter Assy

RETAINER, Spring

RACHET, Starter

SPRING, Friction

SPRING, Ratchet

FAN Cover Assy

Honda GX-390K1SM32 FAN Cover Assy

Cover COMP., FAN

CLIP, Tube

Shroud

Carburetor Assy

Honda GX-390K1SM32 Carburetor Assy

Pilot Screw

Gasket SET

Valve SET, Float

Float SET

AIR Cleaner Assy

Honda GX-390K1SM32 AIR Cleaner Assy

PACKING, Elbow

COVER, AIR Cleaner

GROMET, AIR Cleaner

COLLAR, AIR Cleaner

Muffler Assy

Honda GX-390K1SM32 Muffler Assy

GASKET, EX. Pipe

Muffler Comp DB

PIPE, Exhaust

CAP, Muffler

Fuel Tank Assy

Honda GX-390K1SM32 Fueltank Assy

Ring 14MM

JOINT, Fuel Tank

Tank COMP., Fuel

Fuel Filter

Flywheel Assy

Honda GX-390K1SM32 Flywheel Assy

NUT, Special 16MM

FAN, Cooling

PULLEY, Starter

Flywheel Comp

Ignition Coil Assy

Honda GX-390K1SM32 Ignition Coil Assy

GROMMET, Cord

Coil ASSY., Ignition

Spark Plug CAP

CLAMPER, Cord

Starter Motor Assy

Honda GX-390K1SM32 Starter Motr Assy

Honda GX-390K1SM32 Starter Motor Assy

Control Assy

Honda GX-390K1SM32 Control Assy

ROD, Governor

Adjusting Spring

Wire Holder

ARM, Governor

Control BOX Assy

Honda GX-390K1SM32 Control BOX Assy

Band

Regulator ASSY., Rect

CASE, Control

Panel COMP., Control

Label Assy

Honda GX-390K1SM32 Label Assy

Emblem

Terms and Conditions of Sale Parts

Page

Mexico United Kingdom

United States

Canada